Multi-level stamping die for cold stamping machining

A stamping die and cold stamping technology, applied in the field of multi-stage stamping dies, can solve the problems of increasing equipment costs, affecting the production efficiency of enterprises, and limiting the scope of use of stamping dies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

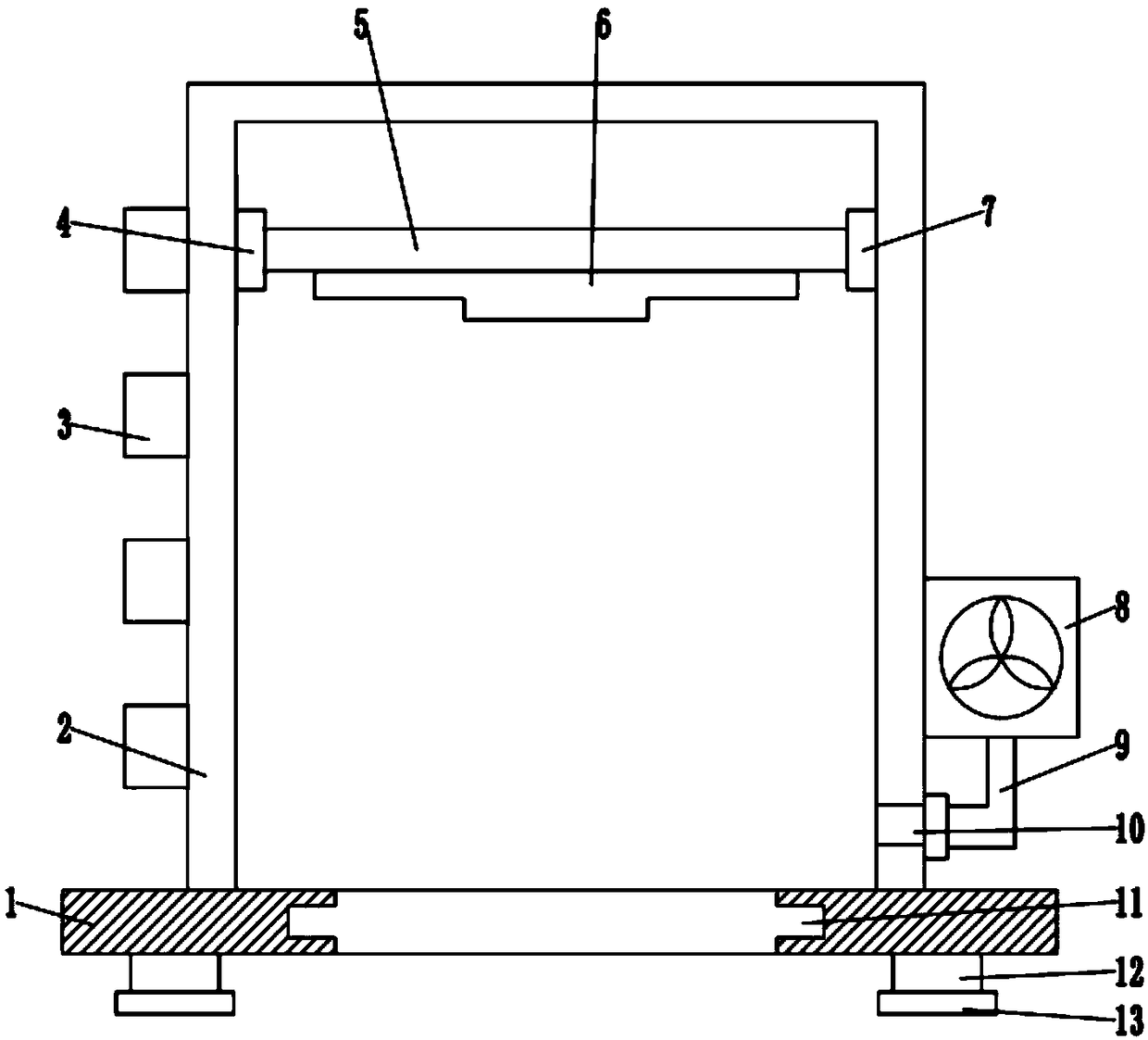

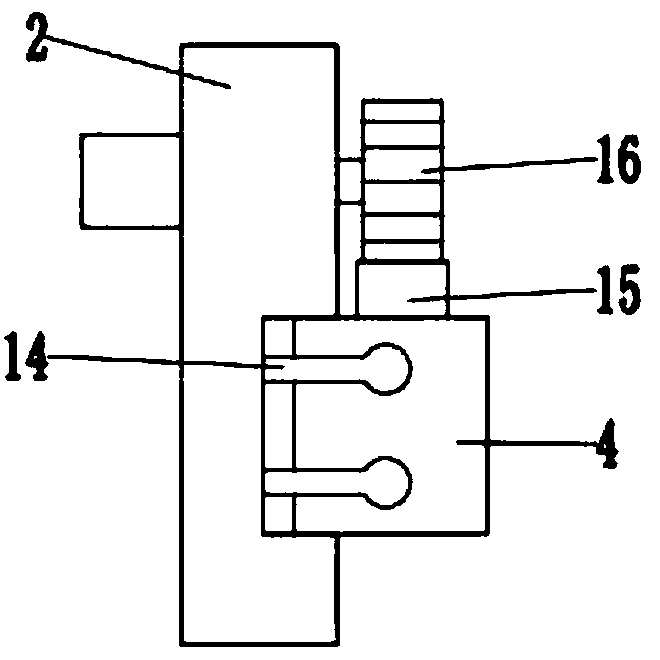

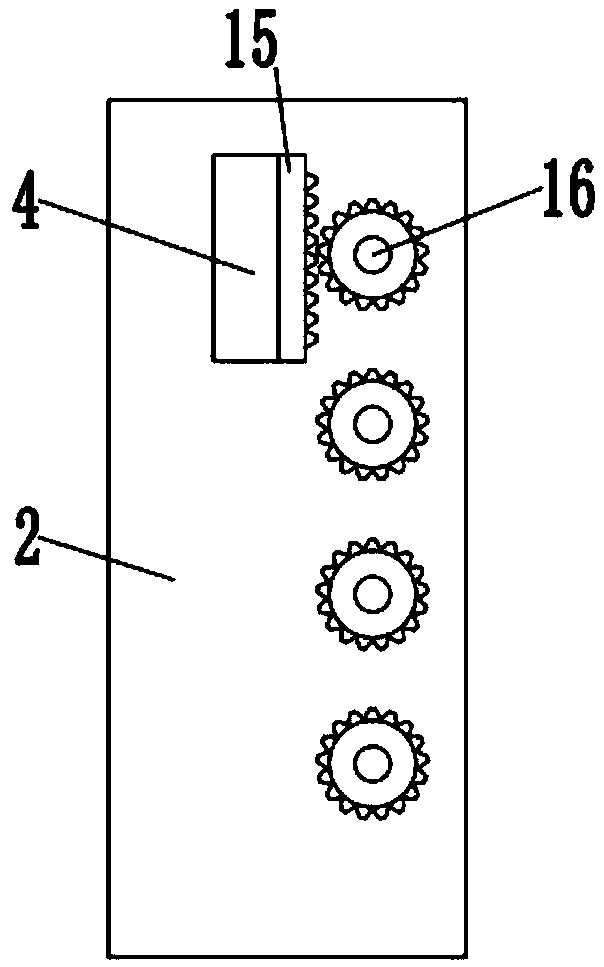

[0024] see Figure 1~3 , in an embodiment of the present invention, a multi-stage stamping die for cold stamping, including a base 1; a frame 2 is fixedly installed on the base 1, the frame 2 is an inverted U-shaped structure, and the inside of the frame 2 A lifting plate 5 is provided, and the inside of the frame 2 is located on the left and right sides of the lifting plate 5, and two chutes are symmetrically opened, and the left and right ends of the frame 2 are slidably installed by the first slider 4 and the second slider 7 respectively. In the inside of the frame 2; two guide rods 14 are symmetrically fixedly installed inside the chute, and the guide rod 14 is a long strip structure composed of a long bar and a cylinder. The first slide block 4 and the second slide block 7. There are guide grooves compatible with the guide rods 14 inside, so that the lifting plate 5 can slide up and down stably inside the chute; the bottom of the lifting plate 5 is fixedly equipped with a...

Embodiment 2

[0028] see Figure 1~4 , in an embodiment of the present invention, a multi-stage stamping die for cold stamping, including a base 1; a frame 2 is fixedly installed on the base 1, the frame 2 is an inverted U-shaped structure, and the inside of the frame 2 A lifting plate 5 is provided, and the inside of the frame 2 is located on the left and right sides of the lifting plate 5, and two chutes are symmetrically opened, and the left and right ends of the frame 2 are slidably installed by the first slider 4 and the second slider 7 respectively. In the inside of the frame 2; two guide rods 14 are symmetrically fixedly installed inside the chute, and the guide rod 14 is a long strip structure composed of a long bar and a cylinder. The first slide block 4 and the second slide block 7. There are guide grooves compatible with the guide rods 14 inside, so that the lifting plate 5 can slide up and down stably inside the chute; the bottom of the lifting plate 5 is fixedly equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com