An x-ray detection device for liquid die forging products

A detection device, liquid die forging technology, applied in the direction of material analysis using radiation, etc., can solve the problems of low sensitivity of T-joint inspection, slow inspection speed, high cost of X-ray film and other equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

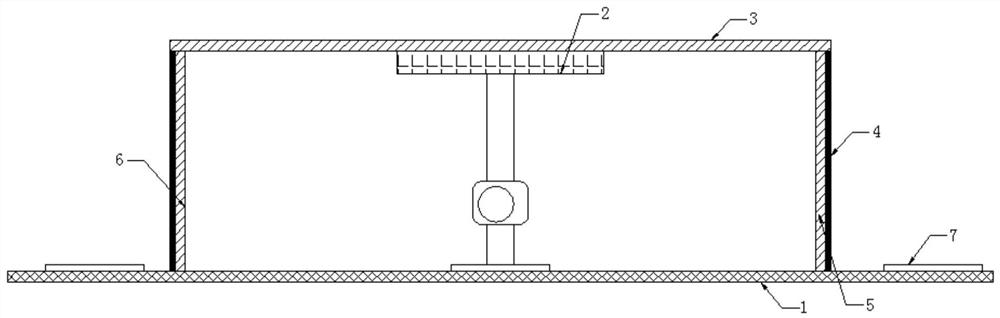

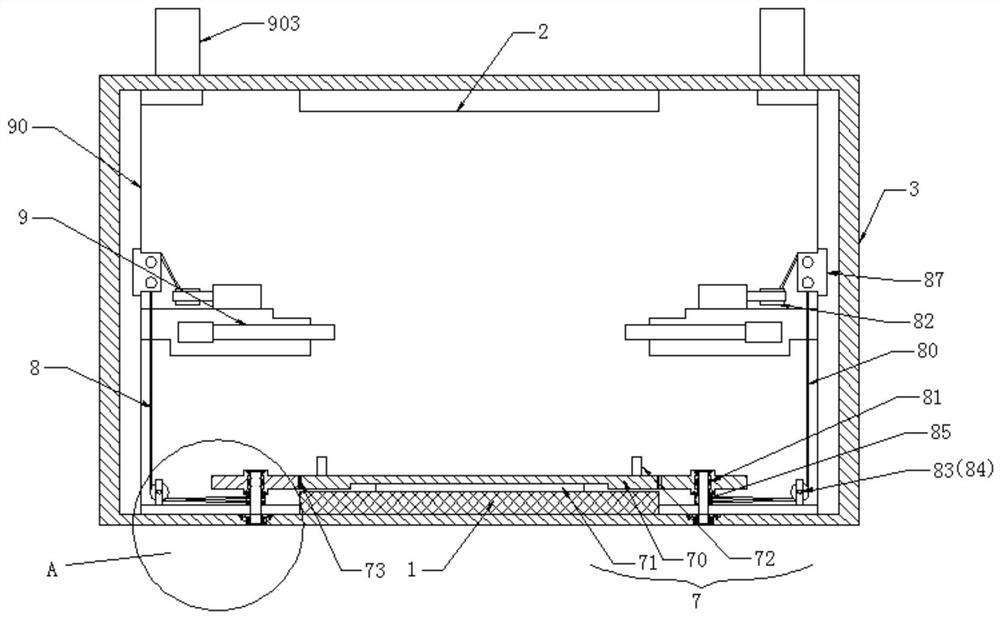

[0031] Please refer to the attached Figure 1-2, an X-ray detection device for liquid die forging products, comprising a belt conveyor 1, a casing 3 provided with X-ray detection electronic equipment 2, the belt conveyor 1 passing through the casing 3, and the casing 3 has an inlet 5 And the outlet 6, and the radiation protection curtain 4 is arranged at the inlet 5 and the outlet 6, and also includes a rotating positioning structure 7, a control device, the rotating positioning structure 7 is installed on the belt of the belt conveyor 1 at an equal distance, and the rotating positioning structure 7 includes A placing end face 70 and a base 71 for placing and positioning the object to be tested, the placing end face 70 is rotatably mounted on the base 71, and a fixing structure 72 is provided on the placing end face 70, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com