Automatic coal feeding loading device

A technology for coal feeding and raw material box, which is applied in the field of automatic coal feeding and feeding devices, can solve the problems of coal sliding, raw material loss, manual feeding, etc., so as to prevent sliding or side leakage, avoid raw material loss, and avoid excessive discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

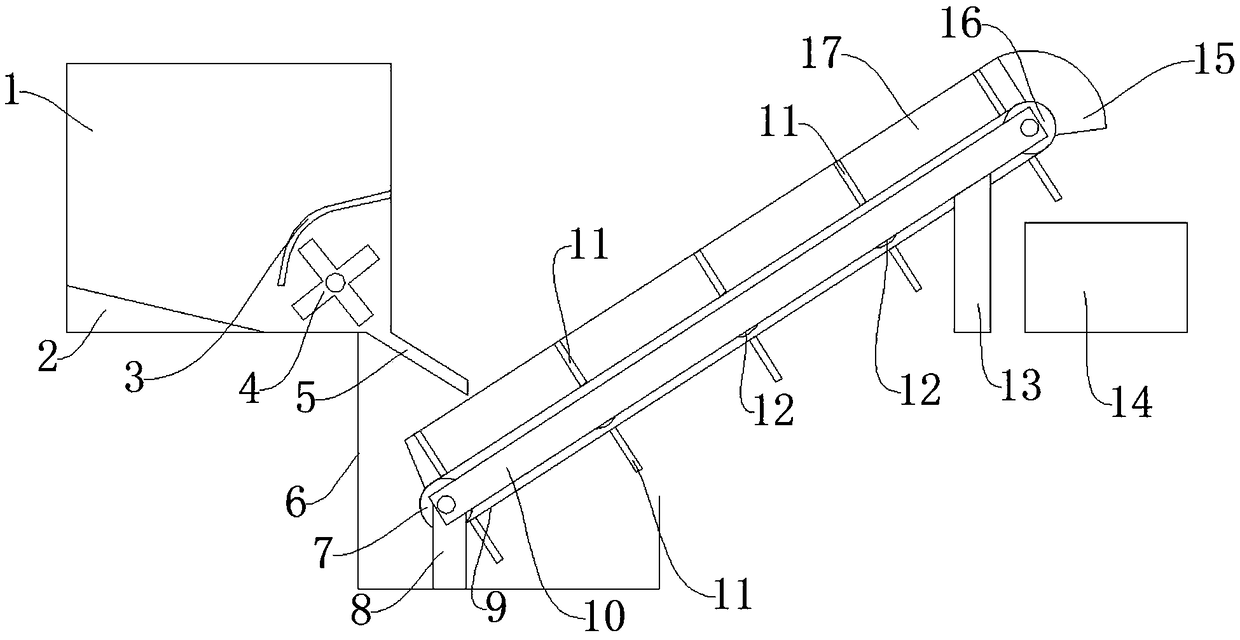

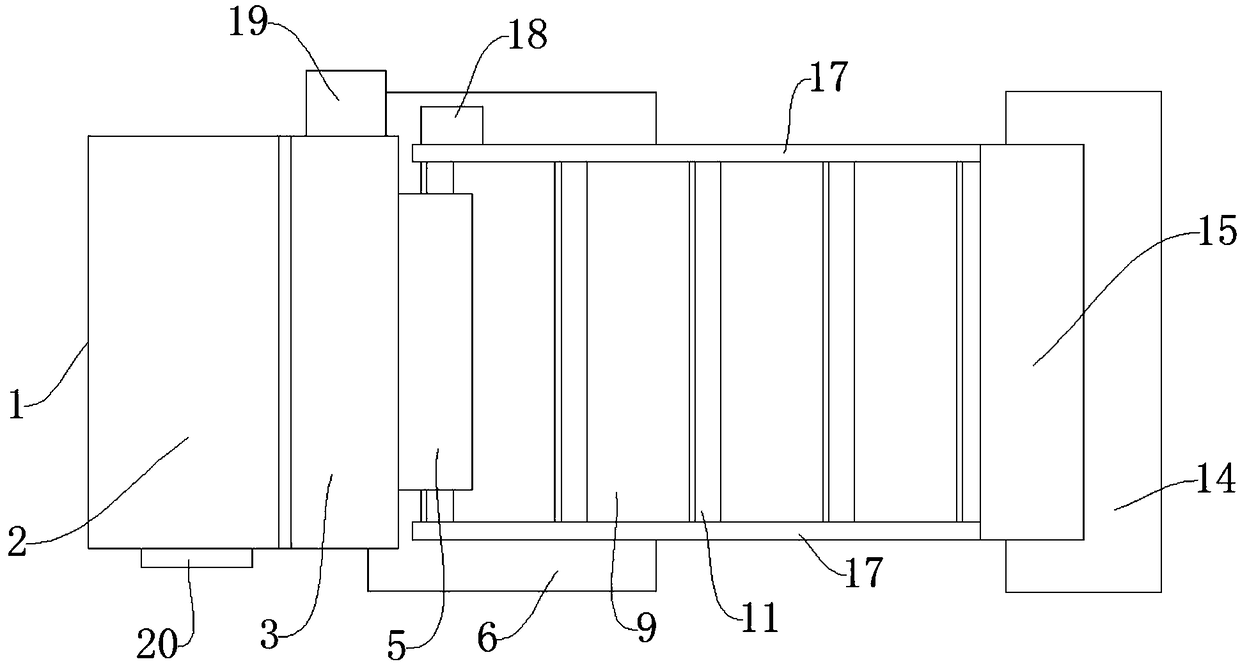

[0019] The present invention will be further explained below in conjunction with the drawings:

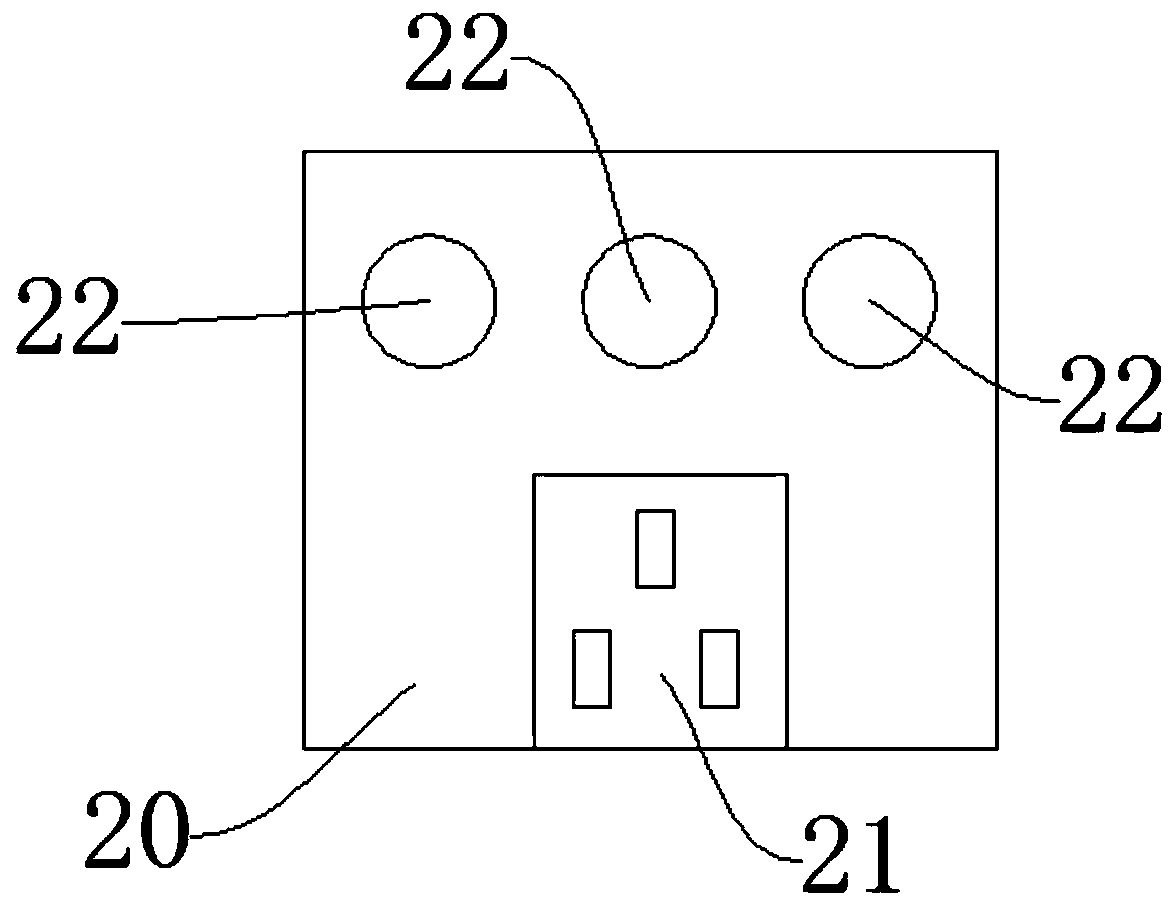

[0020] Such as Figure 1-Figure 3 As shown, an automatic coal feeding device includes a raw material box 1, a slope plate 2, and a baffle plate 3. A slope plate 2 is provided below the inside of the raw material box 1, and the slope plate 2 plays a role of drainage. A baffle plate 3 is provided at the bottom end of the slope plate 2, and the baffle plate 3 plays a role of blocking and protecting materials. A cross plate 4 is provided under the baffle plate 3, and the cross plate 4 plays the role of limiting and discharging. A discharge pipe 5 is arranged under the cross plate 4, and a turning motor 19 is provided behind the raw material box 1. The turning motor 19 drives the turning of the cross plate 4. The turning motor 19 is connected with the raw material box 1 by screws, and the turning motor 19 It is connected with the cross plate 4 through a rotating shaft. The front of the ra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap