Preparation method of mizolastine sustained release preparation

A technology of sustained-release preparations and mizolastine, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc. High production cost and other issues, to achieve the effect of uniform size, good slow-release function and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

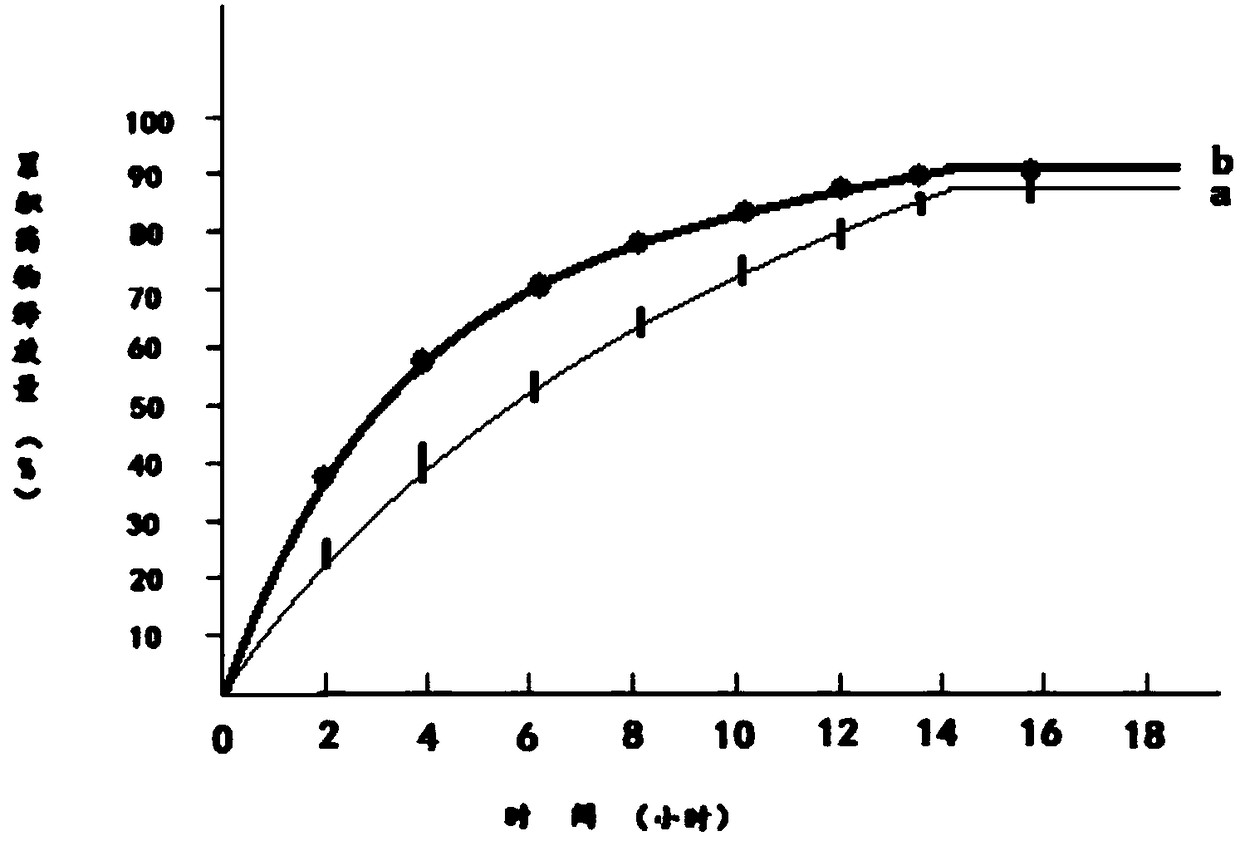

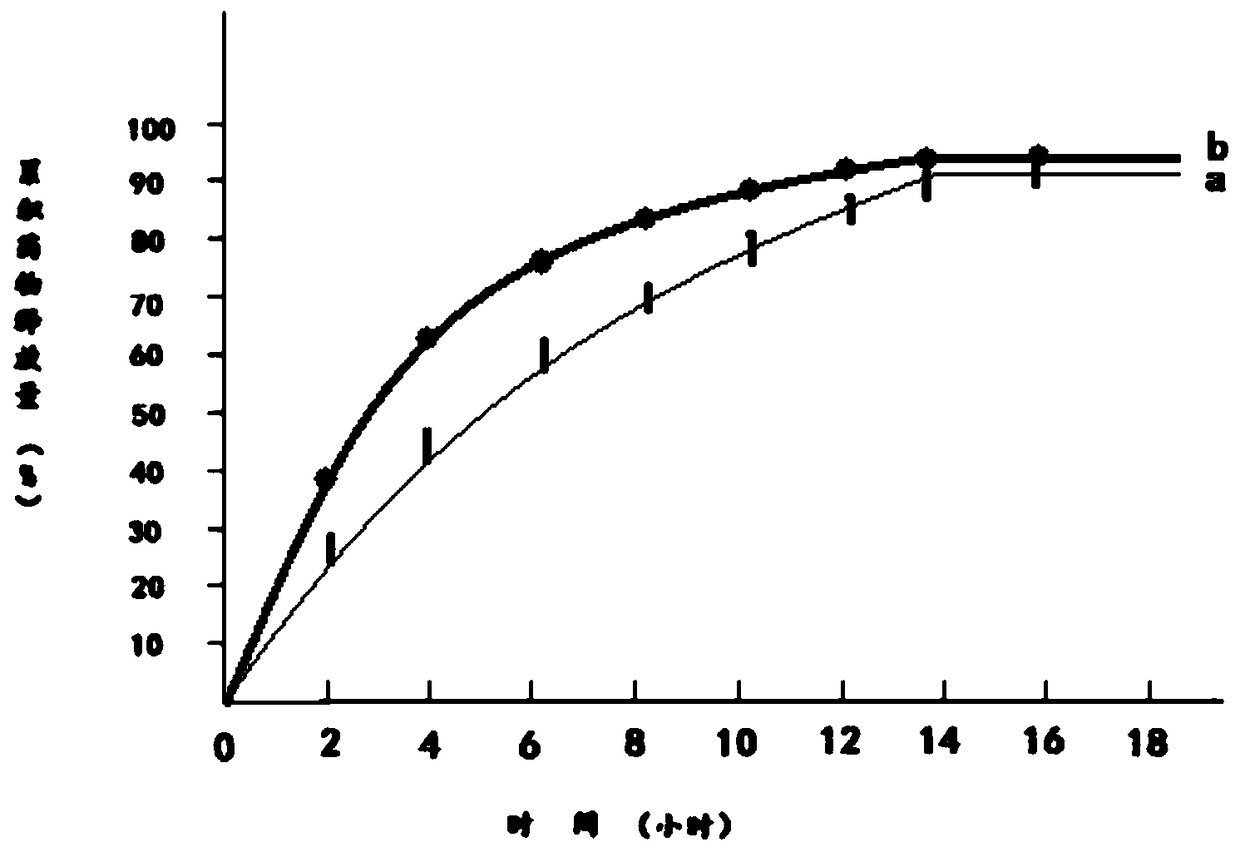

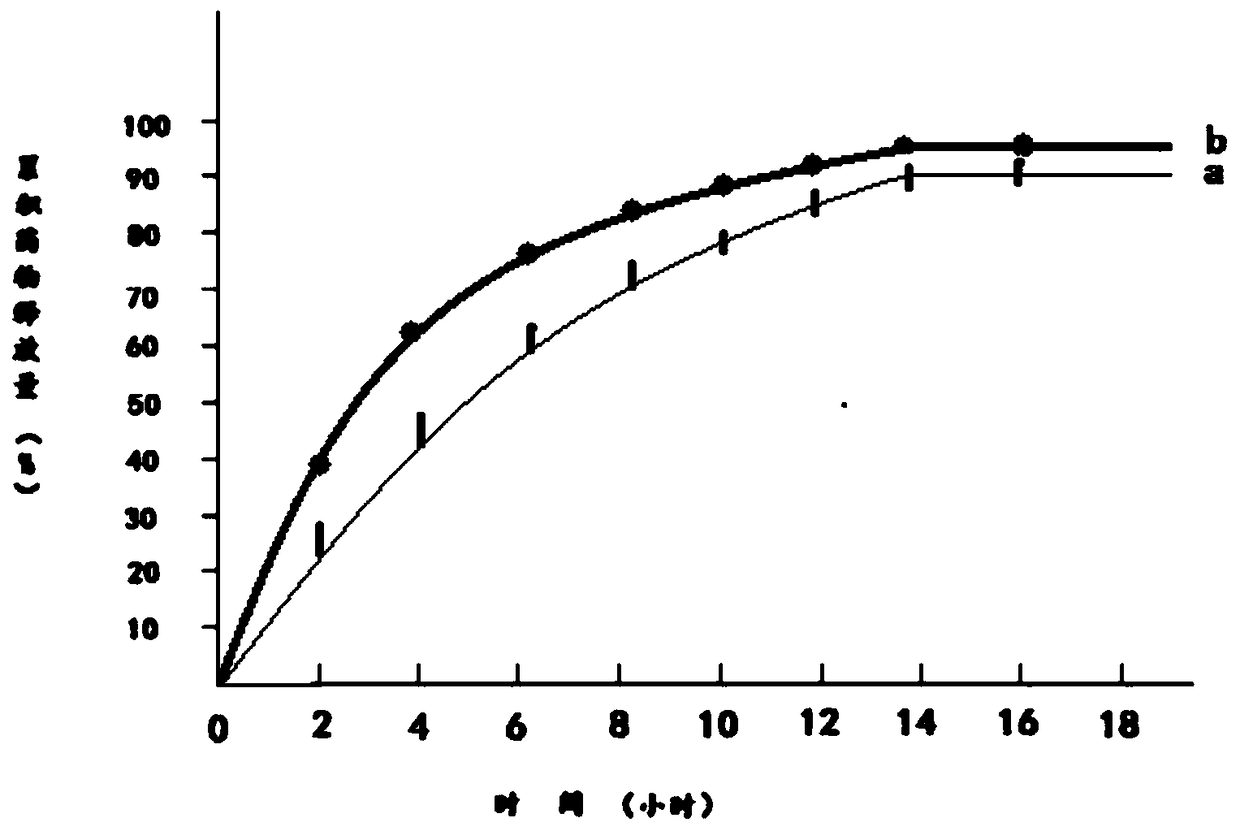

Image

Examples

Embodiment 1

[0023] 1) Dissolve 100 g of mizolastine in 130 g of 95% ethanol to obtain a mizolastine ethanol solution, which is referred to as solution A;

[0024] 2) Add 130g of hydroxypropyl β-cyclodextrin and 20g of mannitol to solution A to obtain solution B;

[0025] 3) Dissolve 100g of polylactic acid and 20g of polyethylene glycol 200 in 100g of acetone to obtain a solution of polylactic acid and polyethylene glycol 200, which is referred to as solution C;

[0026] 4) Mix solution B and solution C to obtain solution D;

[0027] 5) Transfer solution D to a magnetic stirrer, control the temperature of solution D at 15°C to 18°C, continuously stir solution D for 12 hours, then reduce the temperature of solution D to 0°C to 1°C within 2 hours and let it stand for 12 hours. Hours, keep the temperature of solution D at 0°C to 1°C during the standing period;

[0028] 6) Heat the solution D obtained in step 5, and stir continuously for 12 hours when the temperature of the solution D rises...

Embodiment 2

[0032] 1) Dissolve 100 g of mizolastine in 140 g of 95% ethanol to obtain a mizolastine ethanol solution, which is referred to as solution A;

[0033] 2) Add 140g of hydroxypropyl β-cyclodextrin and 25g of mannitol to solution A to obtain solution B;

[0034] 3) Dissolve 120g of polylactic acid and 30g of polyethylene glycol 200 in 120g of acetone to obtain a solution of polylactic acid and polyethylene glycol 200, which is referred to as solution C;

[0035] 4) Mix solution B and solution C to obtain solution D;

[0036] 5) Transfer solution D to a magnetic stirrer, control the temperature of solution D at 15°C to 18°C, continuously stir solution D for 12 hours, then reduce the temperature of solution D to 0°C to 1°C within 2 hours and let it stand for 12 hours. Hours, keep the temperature of solution D at 0°C to 1°C during the standing period;

[0037] 6) Heat the solution D obtained in step 5, and stir continuously for 12 hours when the temperature of the solution D rises...

Embodiment 3

[0041] 1) Dissolve 100 g of mizolastine in 150 g of 95% ethanol to obtain a mizolastine ethanol solution, which is referred to as solution A;

[0042] 2) Add 150g of hydroxypropyl β-cyclodextrin and 30g of mannitol to solution A to obtain solution B;

[0043] 3) Dissolve 140g of polylactic acid and 40g of polyethylene glycol 200 in 140g of acetone to obtain a solution of polylactic acid and polyethylene glycol 200, which is referred to as solution C;

[0044] 4) Mix solution B and solution C to obtain solution D;

[0045] 5) Transfer solution D to a magnetic stirrer, control the temperature of solution D at 15°C to 18°C, continuously stir solution D for 12 hours, then reduce the temperature of solution D to 0°C to 1°C within 2 hours and let it stand for 12 hours. Hours, keep the temperature of solution D at 0°C to 1°C during the standing period;

[0046] 6) Heat the solution D obtained in step 5, and stir continuously for 12 hours when the temperature of the solution D rises...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com