A method of reducing submerged nozzle clogging by calcium aluminum iron alloy treatment

A ferroalloy, immersion technology, applied in the field of steelmaking and refining, to achieve the effect of improving the quality of casting slabs, good castability of molten steel, and reducing the incidence of nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

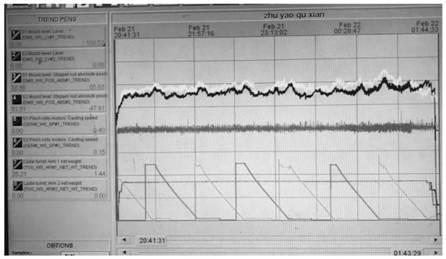

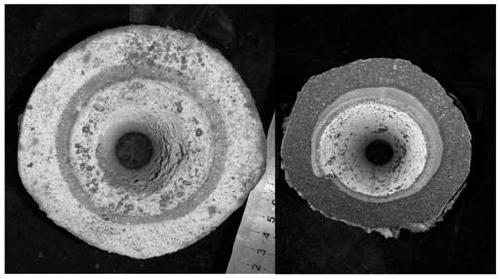

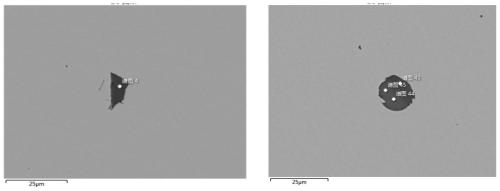

Image

Examples

Embodiment 1

[0032] Smelting a heat of ultra-low carbon SDC04 steel, the converter tapping temperature is 1679°C, the oxygen content at the end point is 527ppm, aluminum slag balls and small grains of lime are added to the steel for slag modification, the RH entry temperature is 1635°C, and the RH refining Carry out natural decarburization, the decarburization time is 15min, use aluminum block for complete deoxidation, Als in steel is 0.015% after deoxidation, after adding aluminum block for 3min, use calcium aluminum iron to adjust the Alt content in steel to 0.042% according to the target, and add Fe at the same time -Ti alloy, RH pure cycle for 8 minutes to break the void, the Ca content of the molten steel in the tundish is controlled at 7ppm, the ultra-low carbon steel is cast in 7 furnaces, the section is 237mm×1800mm, the casting speed is 1.0m / min, and the ultra-low carbon steel is used Mold slag, superheat is controlled at 25°C-40°C, high alkalinity covering agent is used in the tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com