A low-temperature-resistant power cable and preparation method thereof

A power cable and low temperature resistant technology, applied in the field of low temperature resistant power cables and their preparation, can solve the problems of brittle skin, leakage of conductors, loss of elasticity of cables, etc., to reduce corrosion, prolong service life, and have good aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

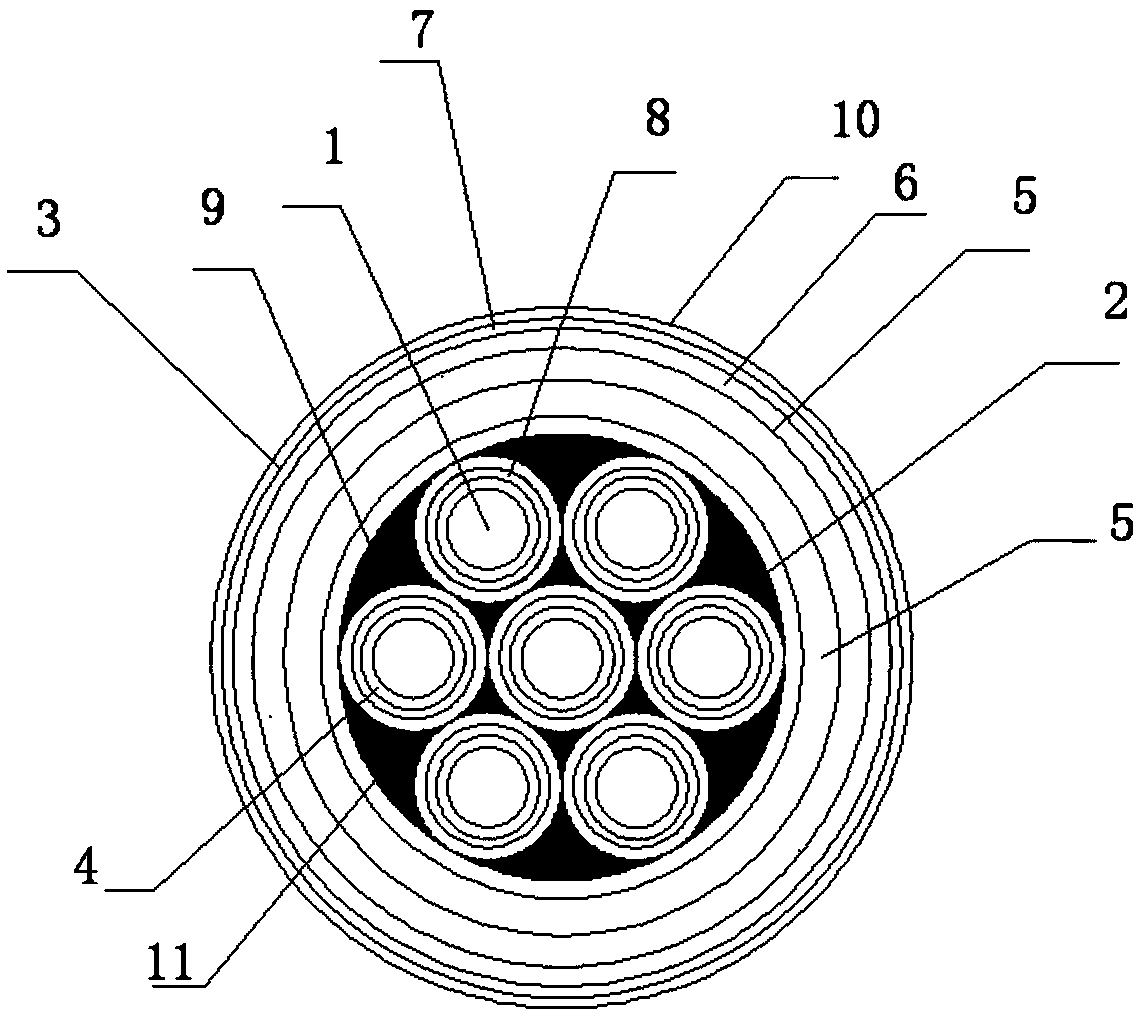

Embodiment 1

[0028] This embodiment provides a low temperature resistant power cable with a structure such as figure 1 As shown, it includes cable core, cable duct 2 and protection tube 3. The cable core is arranged in the cable duct 3, and the outer side of the cable duct 2 is provided with a protection tube 3. The cable core is composed of several conductors 1, one of which is Set in the middle, the rest of the conductors form a ring-shaped junction around the conductor set in the middle, and there is a gap between each conductor, the gap is filled with mica particles 11, and an insulating layer 4 is provided on the outside of each conductor 1, the insulating layer 4. A shielding layer 8 is provided on the outside, a second insulation layer 9 is provided on the outside of the shielding layer 8, a first insulation layer 5 is provided on the outside of the wire conduit 2, and a steel tape armor layer 6 is provided on the outside of the first insulation layer 5. , a pressure-sensitive struc...

Embodiment 2

[0041] This embodiment provides a low temperature resistant power cable with a structure such as figure 1 As shown, it includes cable core, cable duct 2 and protection tube 3. The cable core is arranged in the cable duct 3, and the outer side of the cable duct 2 is provided with a protection tube 3. The cable core is composed of several conductors 1, one of which is Set in the middle, the rest of the conductors form a ring-shaped junction around the conductor set in the middle, and there is a gap between each conductor, the gap is filled with mica particles 11, and an insulating layer 4 is provided on the outside of each conductor 1, the insulating layer 4. A shielding layer 8 is provided on the outside, a second insulation layer 9 is provided on the outside of the shielding layer 8, a first insulation layer 5 is provided on the outside of the wire conduit 2, and a steel tape armor layer 6 is provided on the outside of the first insulation layer 5. , a pressure-sensitive struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com