Environment-friendly material for curing microorganism sludge and application thereof

An environmentally friendly material and microbial technology, applied in the direction of biological sludge treatment, fixed/solidified sludge treatment, water pollutants, etc., can solve problems that have not been effectively and reasonably solved, so as to improve consolidation efficiency, control pollutants, The effect of increasing the strength of silt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

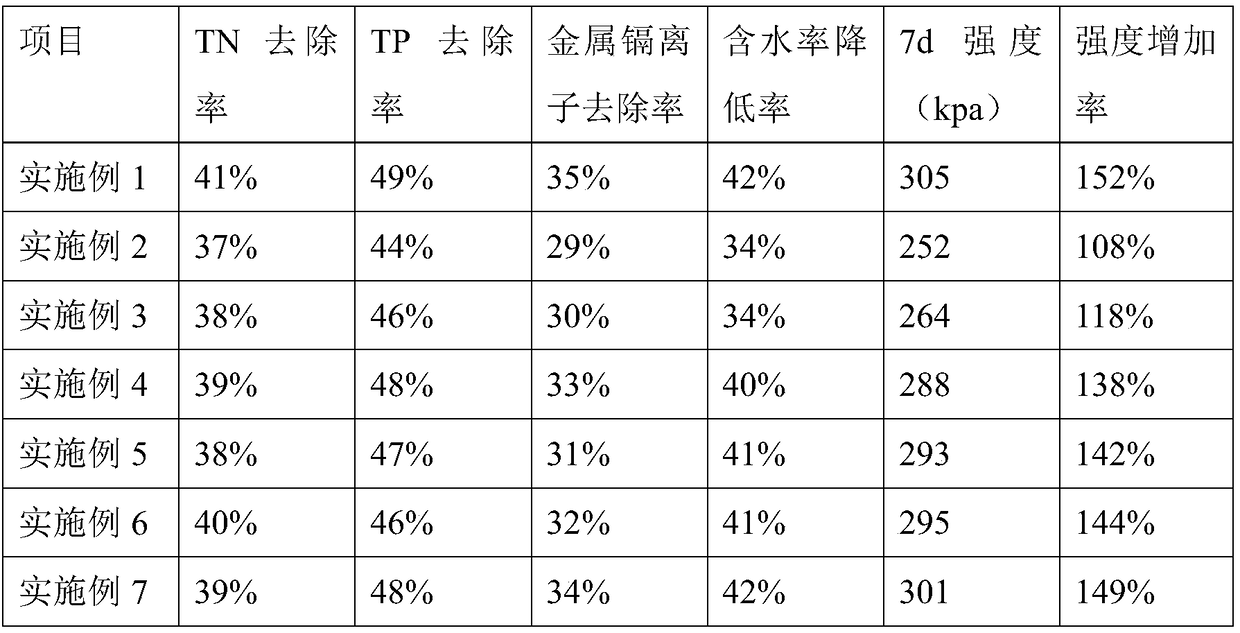

Embodiment 1

[0044]The composition ratio of each component of the microbial sludge solidification environmental protection material is: the composite water treatment bacterial agent is SOUTH RANCH / Nanhua Qianmu's EM bacterial concentrated powder, the bacterial calcium ratio is 1:9, and the amount of calcium chloride added is 3% of the dry weight of the sludge % (1.2g), the amount of cetyltrimethylammonium bromide is 5% (2g) of the dry weight of the sludge, and the amount of LPS is 4% (1.6g) of the dry weight of the sludge. The initial water content of the test sludge is 92.0% , with an initial pH of 9.01 and an organic matter content of 5.31%, dried in an oven and ground through a 100-mesh sieve for later use. Take 40g of air-dried and sieved sludge with an electronic balance, place it in a beaker, add 360g of distilled water, and prepare sludge with a moisture content of 90%, as a blank group. In addition, weigh 40g of air-dried and sieved sludge, add 300g of distilled water, and dissolve...

Embodiment 2

[0046] In this example, the composition ratio of the components of the sludge solidification and environmental protection new material is as follows: the composite water treatment bacterial agent is SOUTHRANCH / Nanhua Qianmu's EM bacterial concentrated powder, the bacterial calcium ratio is 1:8, and the amount of calcium chloride added is silt dry 2% of the weight, cetyl trimethyl ammonium bromide addition is 4% of the dry weight of the sludge, and PAMG addition is 3% of the dry weight of the sludge. The test sludge had an initial moisture content of 92.0%, an initial pH of 9.01, and an organic matter content of 5.31%. It was dried in an oven and ground through a 100-mesh sieve for use. Take 40g of air-dried and sieved sludge with an electronic balance, place it in a beaker, add 360g of distilled water, and prepare sludge with a moisture content of 90%, as a blank group. In addition, weigh 40g of air-dried and sieved sludge, add 300g of distilled water, and dissolve the above-m...

Embodiment 3

[0048] In this example, the composition ratio of the components of the sludge-solidified environmentally friendly new material is: the composite water treatment bacterial agent is SOUTHRANCH / Nanhua Qianmu's EM bacteria concentrated powder, the bacteria-calcium ratio is 1:10, and the amount of calcium chloride added is silt 4% of the dry weight, cetyltrimethylammonium bromide addition is 6% of the dry weight of the sludge, and PAMG addition is 5% of the dry weight of the sludge. The test sludge had an initial moisture content of 92.0%, an initial pH of 9.01, and an organic matter content of 5.31%. It was dried in an oven and ground through a 100-mesh sieve for use. Take 40g of air-dried and sieved sludge with an electronic balance, place it in a beaker, add 360g of distilled water, and prepare sludge with a moisture content of 90%, as a blank group. In addition, weigh 40g of air-dried and sieved sludge, add 300g of distilled water, and dissolve the above-mentioned composite sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com