An aqueous nanometer heating film containing graphene and carbon nanotubes and a preparation method thereof

A technology of carbon nanotubes and graphene, which is applied in the field of water-based nano-heating film and its preparation, can solve the problems of uneven heat generation, non-temperature-resistant, heat-resistant and flame-resistant, and low conversion efficiency of electric-thermal radiation of the heating film, so as to eliminate safety Effects of accidents and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also provides a method for preparing a water-based nano-heating film containing graphene and carbon nanotubes, comprising the following preparation steps:

[0024] (1) According to the design of the water-based nano-heating film, first print the conductive silver paste on the electrode position of the insulating flame-retardant flexible film, and dry it through the drying tunnel;

[0025] (2) The water-based nano-conductive ink containing graphene and carbon nanotubes is coated on the insulating flame-retardant flexible film printed with silver electrodes by gravure printing, or screen printing, or automatically, and dried in a drying tunnel to form a water-based ink. Nano three-dimensional conductive layer.

[0026] (3) According to the design of the water-based nano-heating film, the copper electrode is covered on the silver electrode, and at the same time, it is hot-pressed and laminated with the insulating and flame-retardant flexible film cove...

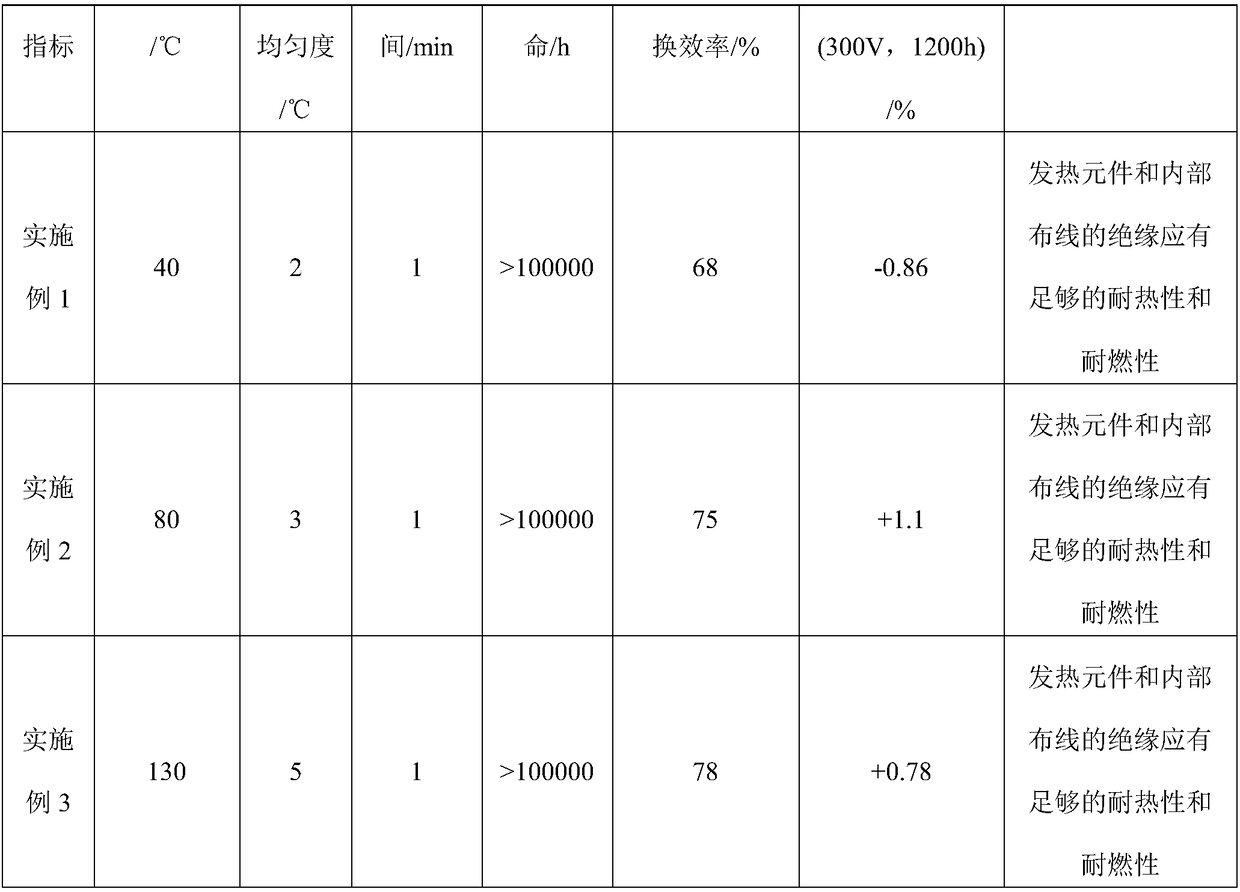

Embodiment 1

[0032] This example is used to illustrate the preparation of a water-based nano-heating film containing graphene and carbon nanotubes by the method of the present invention.

[0033] (1) The surface temperature of the water-based nano-heating film is designed to be 45°C, the power density is 220W / square meter, the working voltage is 220V, and the unit heating area is 0.1 square meters, then the square resistance of the water-based nano-scale three-dimensional conductive layer is: R=2200Ω.

[0034] (2) According to the design, print the conductive silver paste on the flame-retardant PET film and dry it in a 200°C oven. Then, the water-based nano conductive ink containing graphene and carbon nanotubes is gravure printed on the flame-retardant PET printed with silver electrodes, and dried in a 120°C oven to form a water-based nano three-dimensional conductive layer. The water-based nano three-dimensional conductive layer has a layer thickness of 15 microns, wherein the content of...

Embodiment 2

[0036] (1) The surface temperature of the water-based nano-heating film is designed to be 80°C, the power density is 1000W / square meter, the working voltage is 220V, and the unit heating area is 0.5 square meters, then the square resistance of the water-based nano-scale three-dimensional conductive layer is: R=96.8Ω.

[0037] (2) According to the design, print the conductive silver paste on the flame-retardant PI film and dry it in a 200°C oven. Then, the water-based nano conductive ink containing graphene and carbon nanotubes is screen-printed on the flame-retardant PI film printed with silver electrodes, and dried in a 120°C oven to form a water-based nano three-dimensional conductive layer. The water-based nano three-dimensional conductive layer has a layer thickness of 15 microns, wherein the content of graphene is 5%, the content of carbon nanotubes is 7%, the content of nano-conductive carbon black is 32%, the content of water-based resin binder is 36%, and the content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap