Optical fiber protection structure and manufacturing method of optical element

A technology for optical fiber protection and structure, which is applied in the field of optical fiber protection structure and optical element manufacturing, and can solve the problems of deterioration of optical properties of optical fiber, difficult to use curing shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

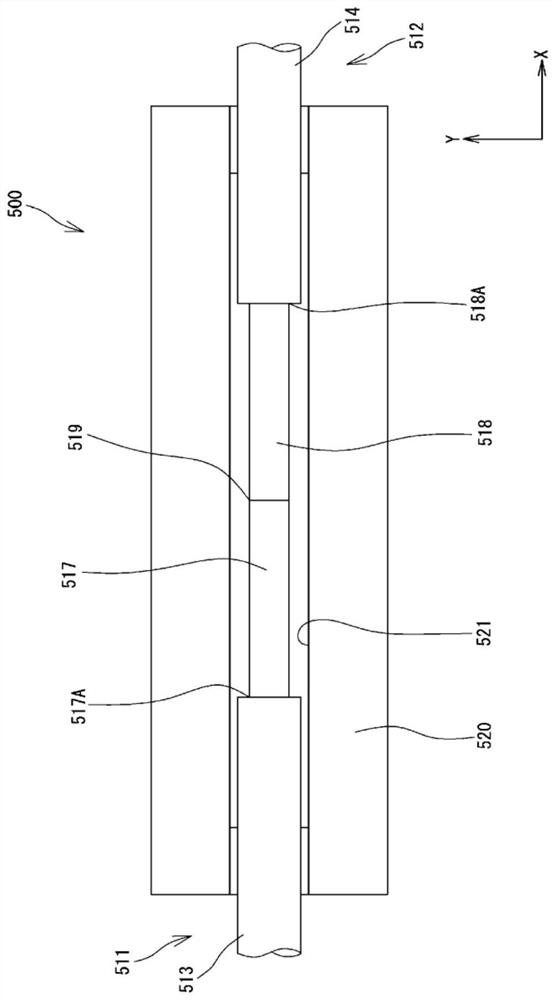

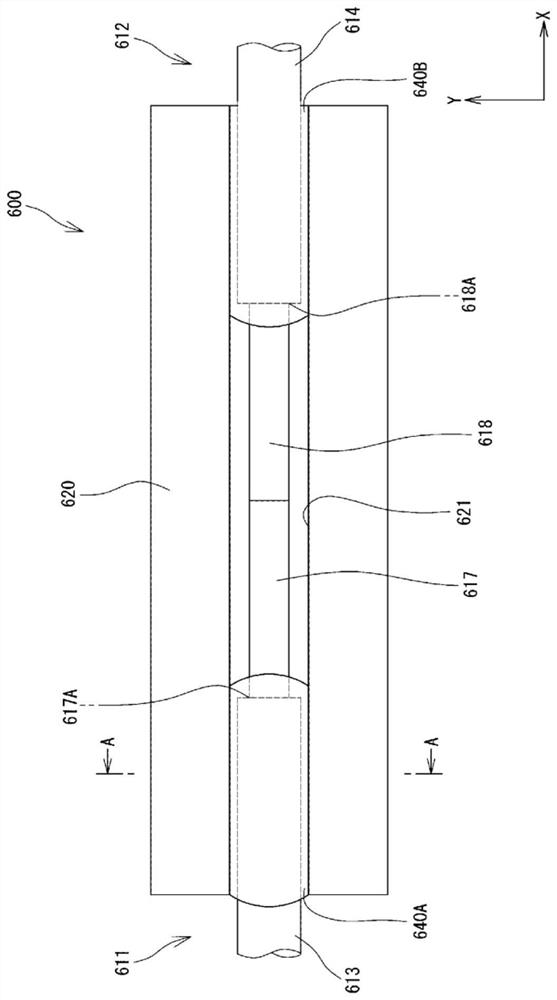

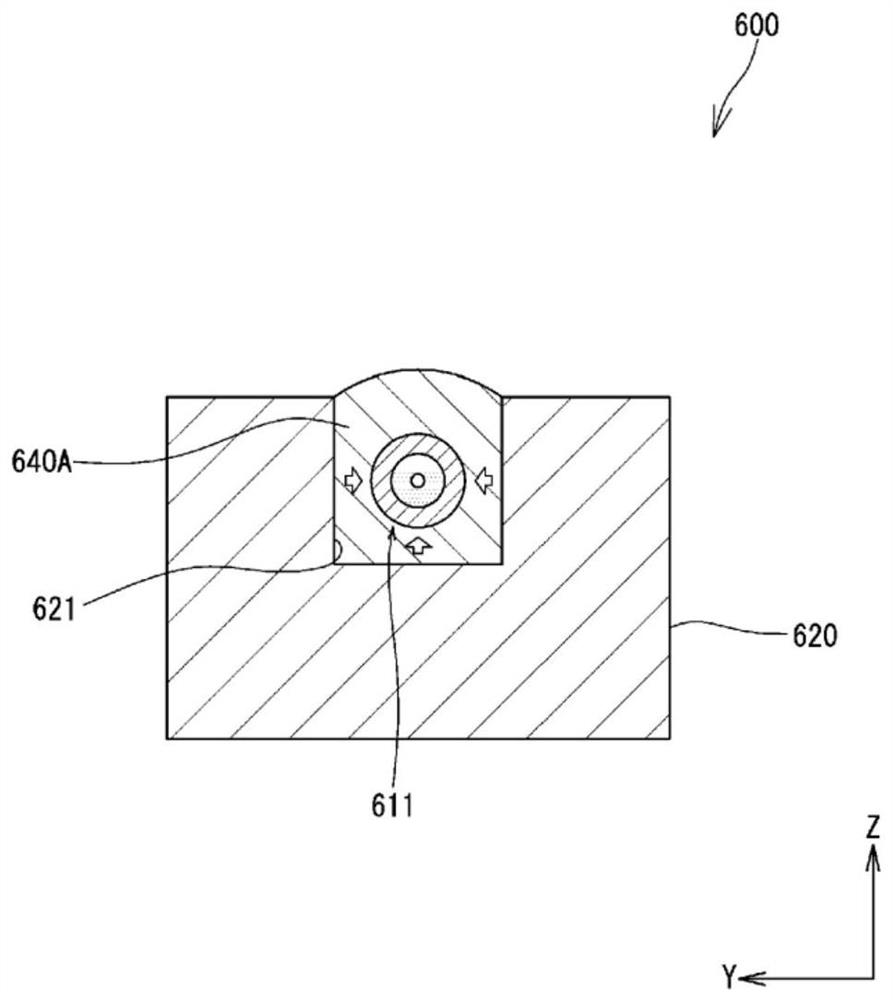

[0050] Below, refer to Figure 5 ~ Figure 20B Embodiments of the optical fiber protection structure and the optical combination structure using the optical fiber protection structure of the present invention will be described in detail. exist Figure 5 ~ Figure 20B In , the same reference numerals are attached to the same or corresponding constituent elements, and repeated explanations are omitted. In addition, in Figure 5 ~ Figure 20B In some cases, the scale and size of each constituent element may be exaggerated, and some constituent elements may be omitted.

[0051] Figure 5 It is a plan view showing the light combining path structure 1 in the first embodiment of the present invention, Figure 6 yes Figure 5 The BB line section view. Such as Figure 5 as well as Figure 6 As shown, the optical combiner structure 1 includes: an optical combiner 10 , which includes mutually fused optical fibers 11 , 12 ; and a fiber housing portion 20 , which protects the fused po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com