Processing technology of polymeric ferric sulfate

A technology for polymerizing ferric sulfate and processing technology, applied in the direction of ferric sulfate, etc., can solve the problems of inconvenient installation and disassembly of the filter screen, the modifier has no adsorption effect, and the nitrite ion is easy to exceed the standard, and achieves a large degree of molecular polymerization. , the effect of improving flocculation performance and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

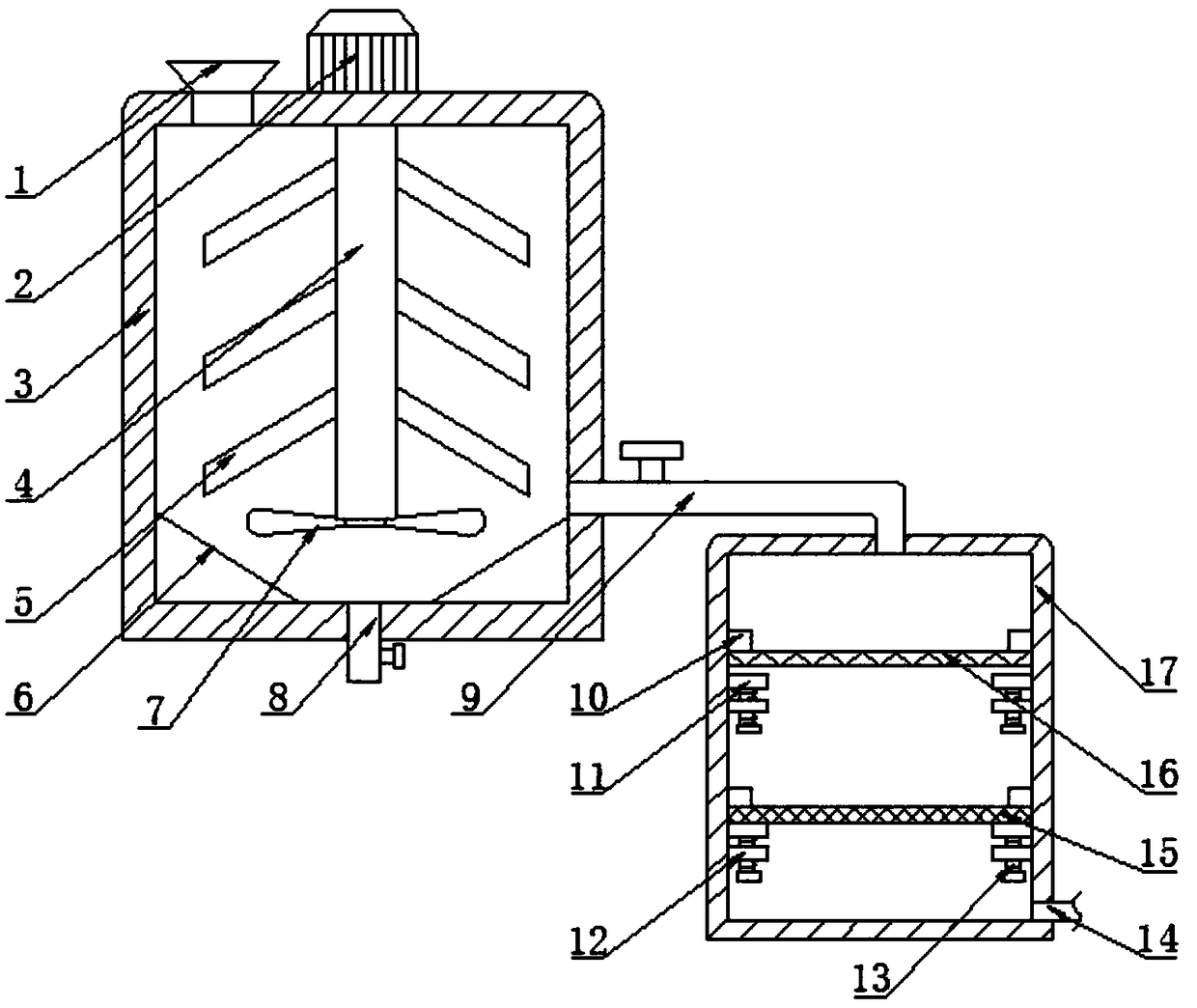

Method used

Image

Examples

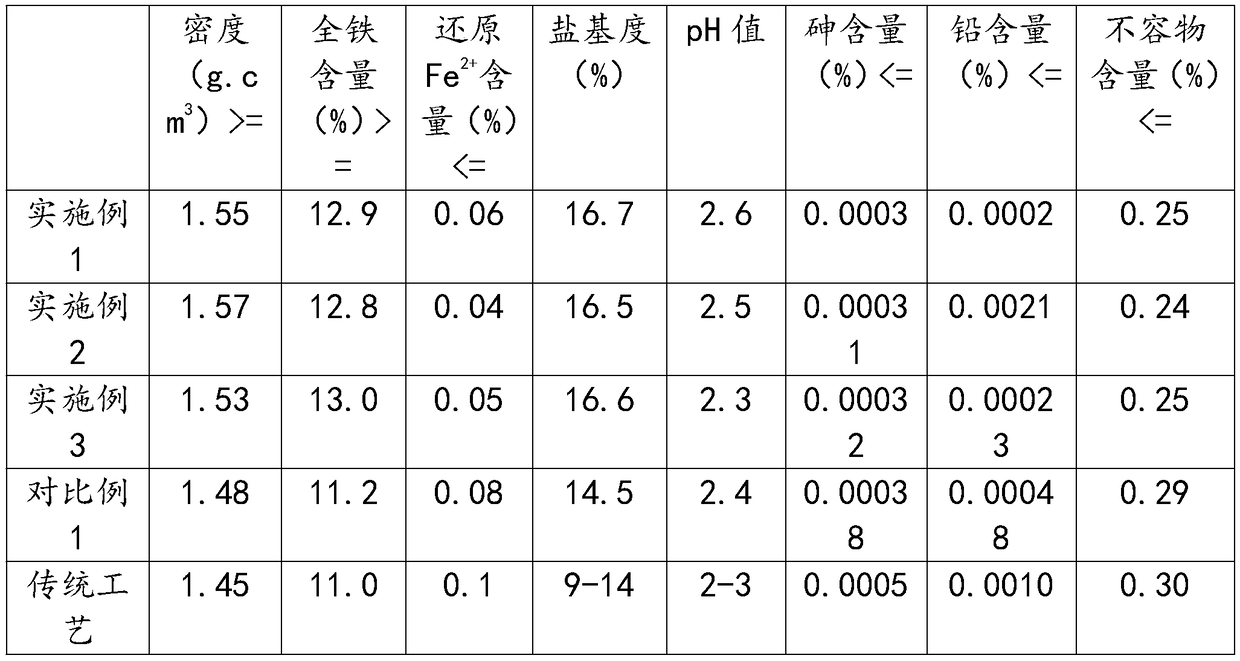

Embodiment 1

[0032] A processing technique for polyferric sulfate, comprising the following steps:

[0033] 1) Add 300Kg of tap water to the closed reaction kettle, then start stirring, slowly add 0.9t of ferrous sulfate heptahydrate, and add 100Kg of the required dilute titanium white acid under the condition of stirring. After adding, heat the closed reaction kettle with steam, stop feeding steam after heating up to 30°C, and close the steam valve after the ferrous sulfate heptahydrate is completely dissolved, and open the cooling circulating water outlet valve;

[0034] 2) After stirring for 5 minutes, stop stirring, open the bottom valve of the closed reaction kettle, open the inlet and outlet valves of the circulation pump, and turn on the circulation pump. For the first time, 10Kg of solid sodium nitrite and 500g of sodium iodide are prepared into a solution, and then poured into the closed reaction kettle Add in, stir and mix evenly, the stirring time is 20 minutes, and carry out ta...

Embodiment 2

[0045] A processing technique for polyferric sulfate, comprising the following steps:

[0046] 1) Add 350Kg of tap water to the closed reaction kettle, then start stirring, slowly add 1.1t of ferrous sulfate heptahydrate, and add 120Kg of the required dilute titanium white acid under the condition of stirring, and the waste dilute titanium white acid is 15 minutes After adding, heat the closed reaction kettle with steam, stop feeding steam after heating up to 35°C, and close the steam valve after ferrous sulfate heptahydrate is completely dissolved, and open the outlet valve of cooling circulating water;

[0047] 2) After stirring for 5 minutes, stop stirring, open the bottom valve of the closed reaction kettle, open the inlet and outlet valves of the circulation pump, and turn on the circulation pump. For the first time, 10Kg of solid sodium nitrite and 500g of sodium iodide are prepared into a solution, and then poured into the closed reaction kettle Add in, stir and mix eve...

Embodiment 3

[0058] A processing technique for polyferric sulfate, comprising the following steps:

[0059] 1) Add 330Kg of tap water to the closed reaction kettle, then start stirring, slowly add 1t of ferrous sulfate heptahydrate, and add 110Kg of the required dilute titanium white acid under the condition of stirring, and add the dilute titanium white acid in 15 minutes After finishing, heat the closed reaction kettle with steam, stop feeding the steam after heating up to 35°C, until the ferrous sulfate heptahydrate is completely dissolved, close the steam valve, and open the cooling circulating water outlet valve;

[0060] 2) After stirring for 5 minutes, stop stirring, open the bottom valve of the closed reaction kettle, open the inlet and outlet valves of the circulation pump, and turn on the circulation pump. For the first time, 10Kg of solid sodium nitrite and 500g of sodium iodide are prepared into a solution, and then poured into the closed reaction kettle Add in, stir and mix ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com