An epoxy resin dry-type transformer mold

A dry-type transformer and epoxy resin technology, applied in the field of transformers, can solve the problems of increasing mold cost, low mold utilization rate, mold management and inconvenience in use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

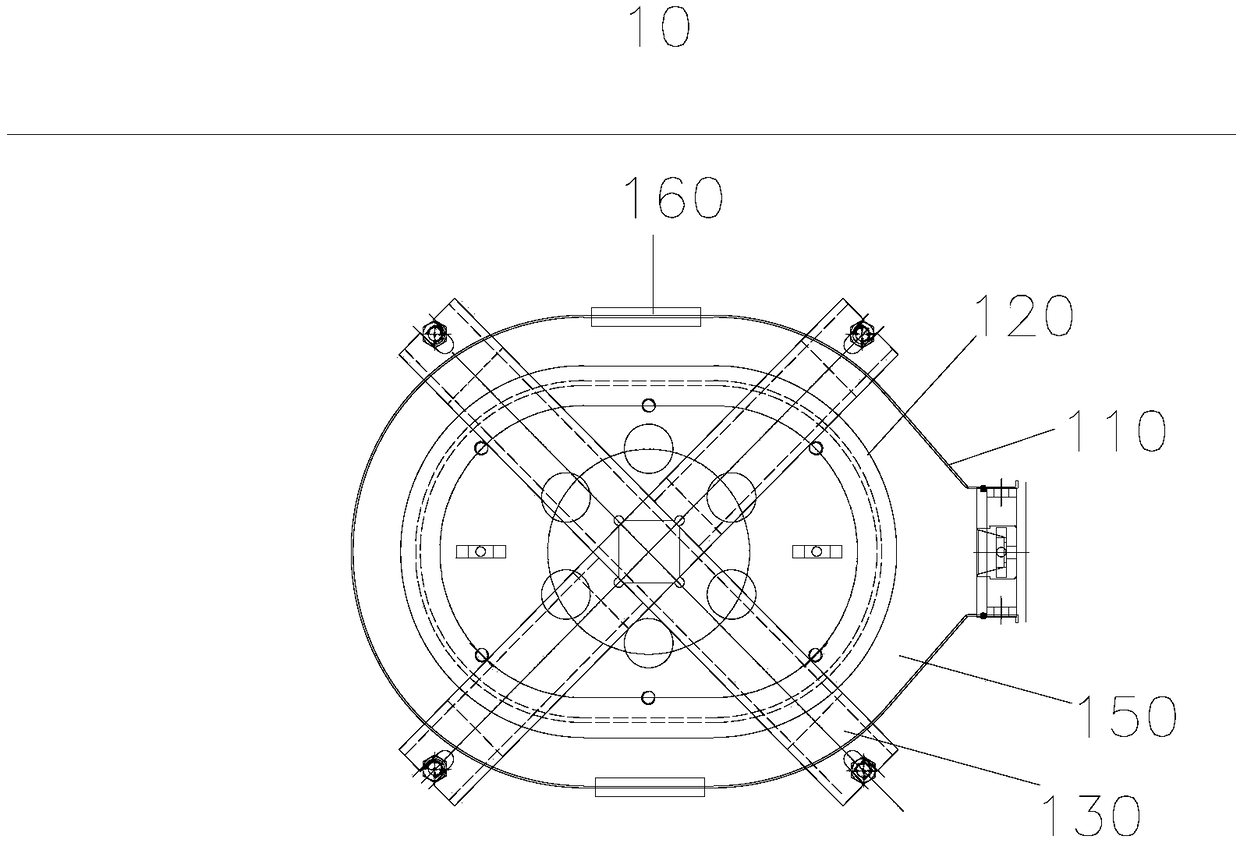

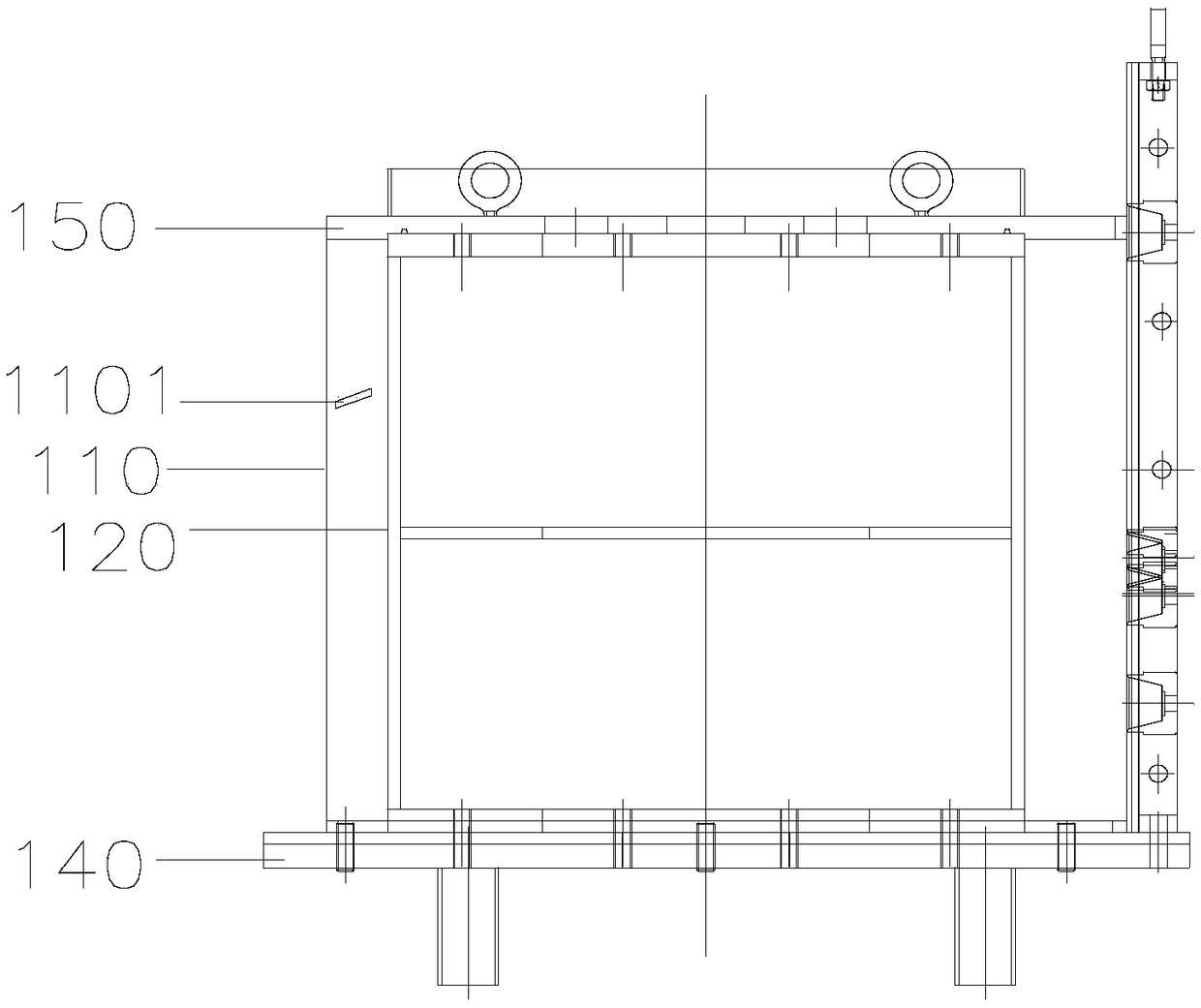

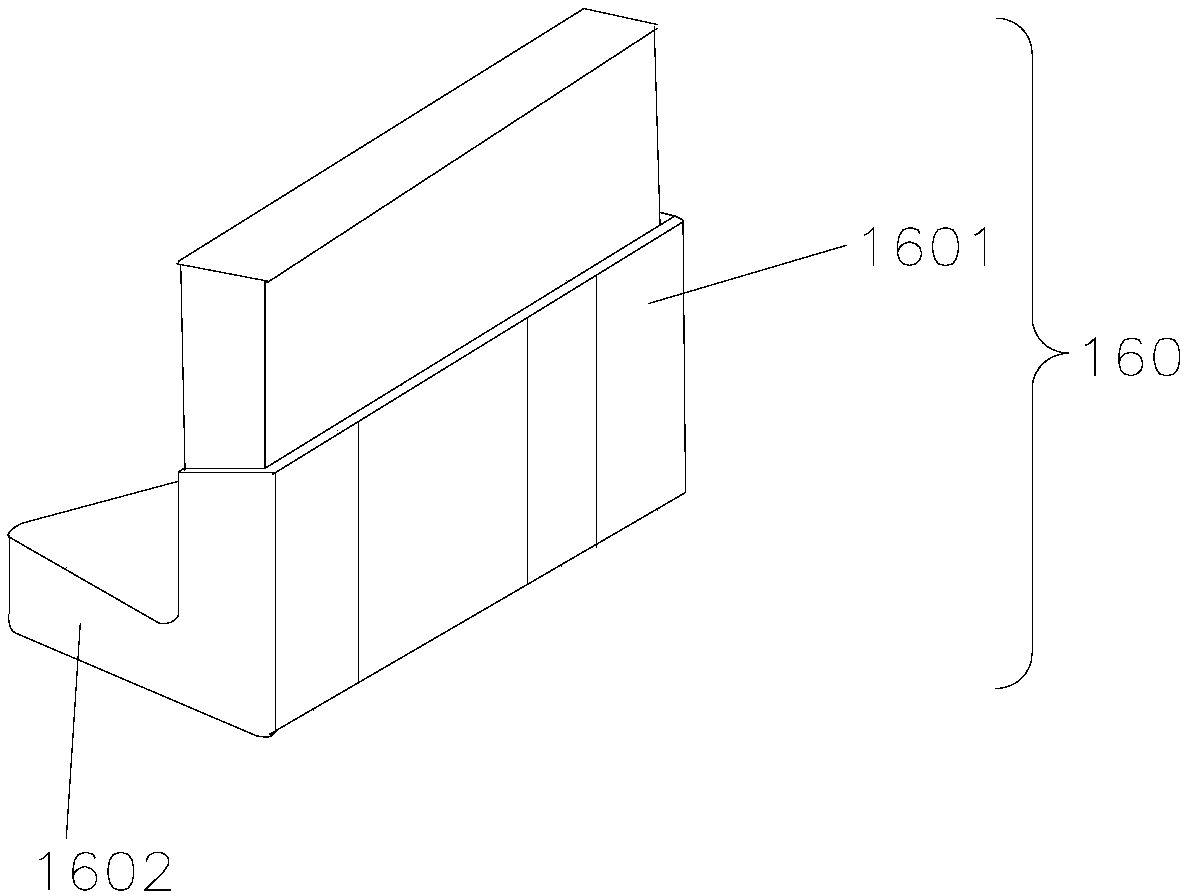

[0036] see Figure 1A , Figure 1B as well as figure 2, the present invention provides an epoxy resin dry-type transformer mold, including a high-voltage mold 10, and the high-voltage mold 10 includes an outer mold 110, an inner mold 120, a cross press frame 130, a bottom plate 140, and a support plate for adjusting the height of the coil 150, the outer mold 110 is sleeved outside the inner mold 120, a cavity is formed between the outer mold 120 and the inner mold 110, the transverse section of the cavity is circular, the outer mold 110 and the inner mold 110 The lower end of the inner mold 120 is connected to the bottom plate 140, the cross press frame 130 is arranged on the upper end of the outer mold 110 and connected to the bottom plate 140 through a screw, and the support plate 150 is arranged between the outer mold 110 and the inner mold 110. Between the molds 120 is used to seal the upper end of the cavity, and the support plate 150 can slide up and down along the cav...

Embodiment 2

[0050] see Figure 3A , Figure 3B as well as Figure 4 , the present invention provides an epoxy resin dry-type transformer mold, including a low-voltage mold 20, the low-voltage mold 20 includes a cylinder 210, the cross-section of the cylinder 210 is oval with one end cut off, the cylinder One end of the cylinder 210 is provided with a baffle 220 that can move up and down along the cylinder 210 , and the baffle 220 is sleeved on the outer surface of the cylinder 210 .

[0051] Since the low-voltage molds 20 of SCB12 and SCB13 type epoxy resin dry-type transformers are only different in height under the same voltage level, so in this embodiment, when the baffle 220 is located on the cylinder 210 At the edge, it corresponds to the coil height of the low-voltage mold 20 of the SCB13-type epoxy resin dry-type transformer. When the baffle 220 slides down the preset distance along the barrel 210, it can become the low-voltage mold 20 of the SCB12 type dry-type transformer, whe...

Embodiment 3

[0064] An epoxy resin dry-type transformer mold combination includes a high-voltage mold 10 and a low-voltage mold 20 . The epoxy resin dry-type transformer mold includes the high-voltage mold 10 as described in Embodiment 1 and the low-voltage mold 20 as described in Embodiment 2. After the low-voltage coil is wound, the low-voltage mold 20 is taken out, after the high-voltage coil is wound, epoxy resin is poured, and the high-voltage mold 10 is taken out after the casting, so as to form an epoxy resin dry-type transformer.

[0065] In this embodiment, the epoxy resin dry-type transformer mold is applicable to both SCB12 and SCB13 type epoxy resin dry-type transformers.

[0066] In this embodiment, the epoxy resin dry-type transformer mold includes a high-voltage mold 10 and a low-voltage mold 20. The high-voltage mold 10 adjusts the height of the coil through the support plate 150, and the low-voltage mold 20 can adjust the height of the coil through the baffle 220. At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com