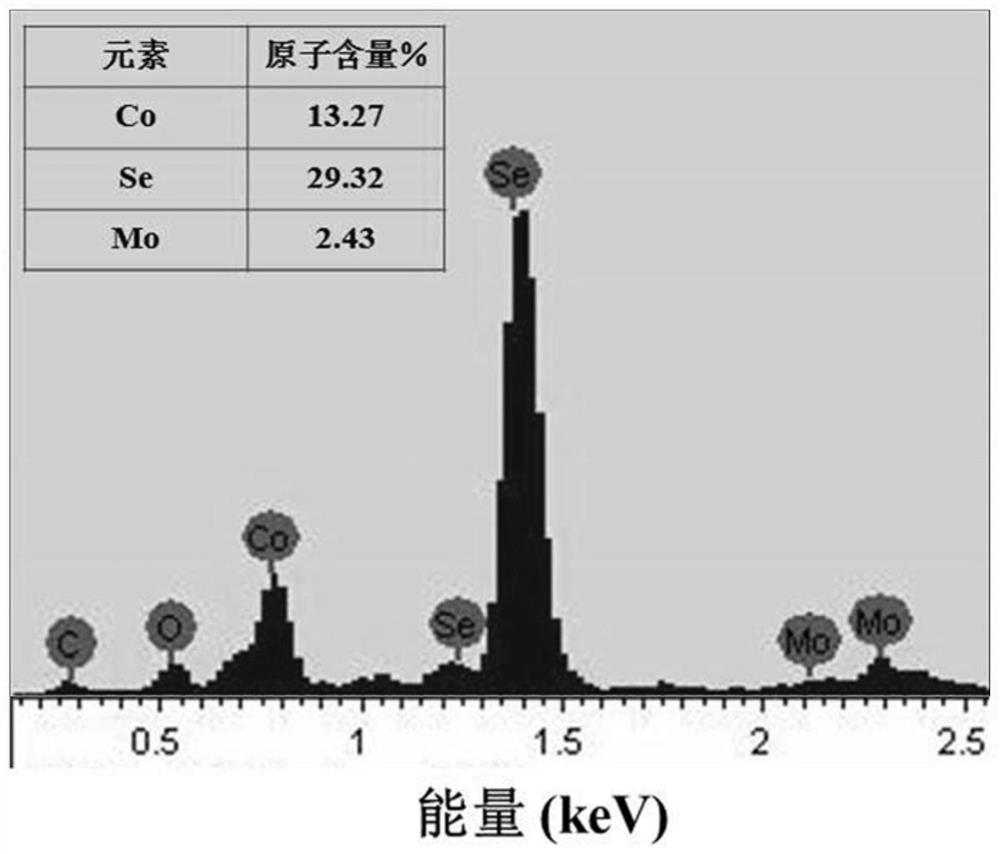

A hollow tubular cobalt-selenium compound/molybdenum-selenium compound composite nanomaterial and its preparation method and application

A technology of composite nanomaterials and selenium compounds, applied in the field of preparation of inorganic micro-nanomaterials, can solve the problems of poor conductivity, limited catalytic performance, insufficient lamellar catalytic active sites, etc., and achieves controllable reaction, mature and stable process, excellent electrical Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

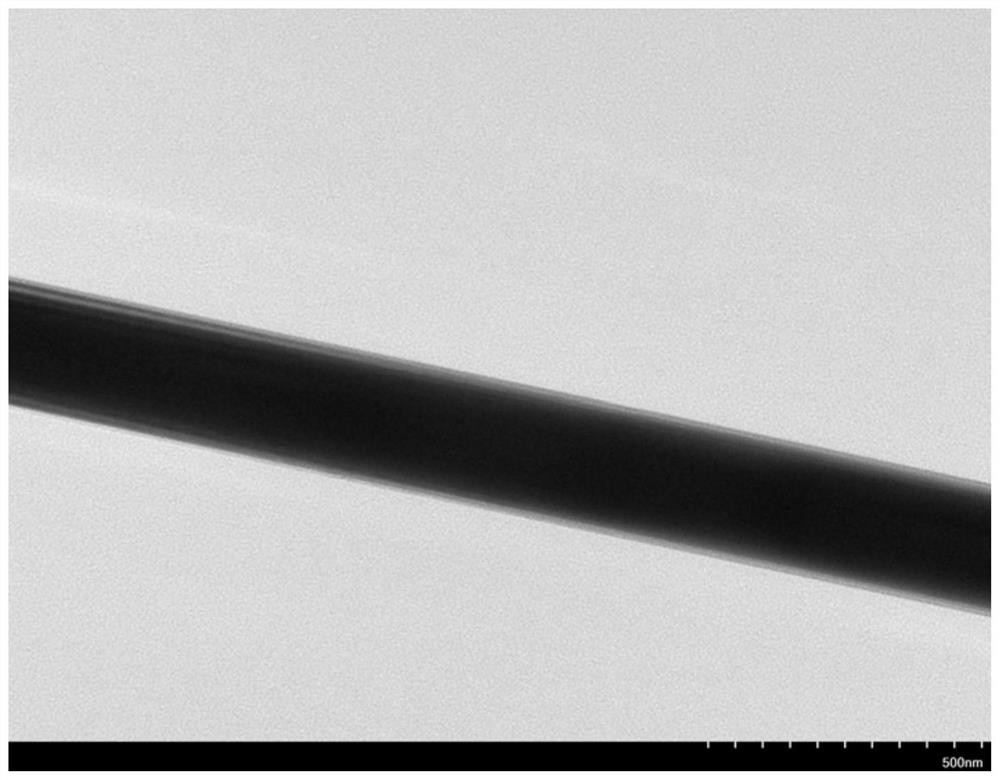

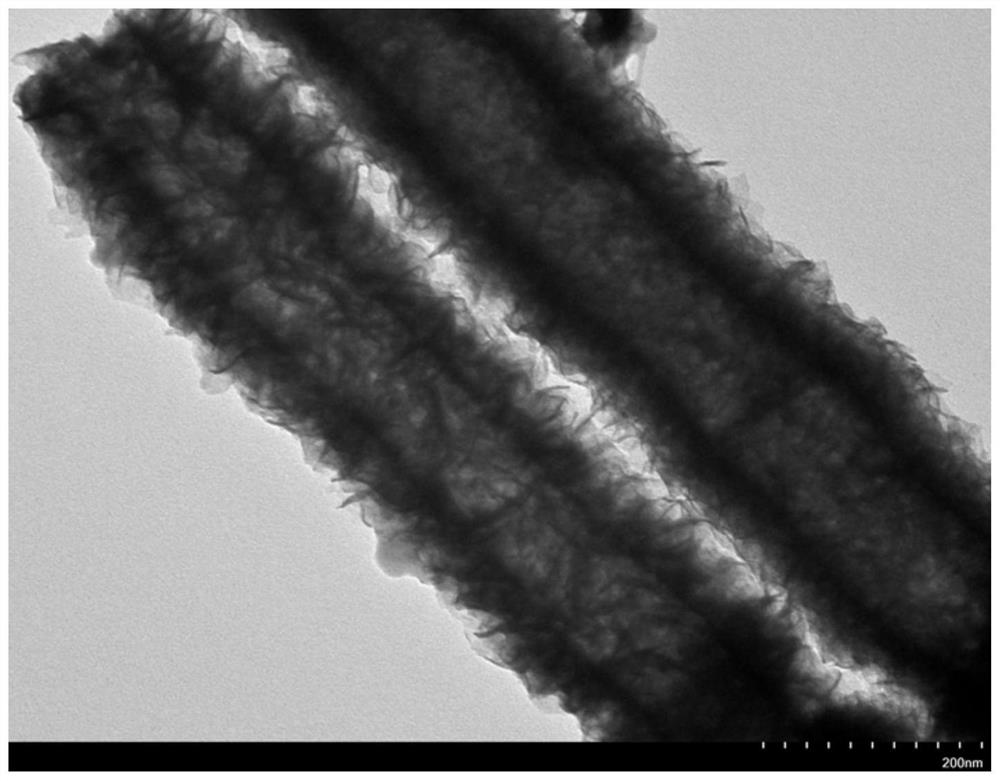

[0037] A hollow tubular CoSe 2 / MoSe 2 A method for preparing a composite nanomaterial, comprising the steps of:

[0038] A. Weigh 1.5mmol cobalt chloride hexahydrate and 3mmol urea, add 30ml deionized water and stir until dissolved to obtain a clear and transparent solution; transfer the solution to a reaction kettle lined with tetrafluoroethylene, close the reaction kettle and put In a constant temperature box, heat at 90°C for 12h;

[0039] B. After the reaction, the cooled liquid in the reaction kettle was centrifuged to separate the solid product, and after the solid product was cleaned several times, it was placed in a vacuum drying oven and dried at 60°C for 6 hours;

[0040] C, weigh 0.12g of the product obtained in step B, add 30mL N, N-dimethylformamide, stir to make it uniformly dispersed; then add 0.45mmol sodium molybdate (Na 2 MoO 4 ), stirred until completely dissolved;

[0041] D. Add 2mmol of selenium powder into 2mL of hydrazine hydrate, stir until disso...

Embodiment 2

[0047] A hollow tubular CoSe 2 / MoSe 2 A method for preparing a composite nanomaterial, comprising the steps of:

[0048] A. Weigh 2mmol cobalt chloride hexahydrate and 2mmol urea, add 30ml deionized water and stir until dissolved to obtain a clear and transparent solution; transfer the solution to a reaction kettle lined with tetrafluoroethylene, close the reaction kettle and put it into a constant temperature In the oven, heat at 120°C for 10h;

[0049] B. After the reaction, the cooled liquid in the reaction kettle was centrifuged to separate the solid product, and after the solid product was cleaned several times, it was placed in a vacuum drying oven and dried at 60°C for 6 hours;

[0050] C, weigh 0.3g of the product obtained in step B, add 50mL N, N-dimethylformamide, stir to make it uniformly dispersed; then add 0.8mmol sodium molybdate (Na 2 MoO 4 ), stirred until completely dissolved;

[0051] D. Add 3mmol of selenium powder into 3mL of hydrazine hydrate, stir u...

Embodiment 3

[0055] A hollow tubular CoSe 2 / MoSe 2 A method for preparing a composite nanomaterial, comprising the steps of:

[0056] A. Weigh 1mmol cobalt nitrate hexahydrate and 2mmol urea, add 20ml deionized water and stir until dissolved to obtain a clear and transparent solution; transfer the solution to a reaction kettle lined with tetrafluoroethylene, close the reaction kettle and put it into a constant temperature box , at 140°C, heating for 8h;

[0057] B. After the reaction, the cooled liquid in the reaction kettle was centrifuged to separate the solid product, and after the solid product was cleaned several times, it was placed in a vacuum drying oven and dried at 60°C for 6 hours;

[0058] C, weigh 0.2g of the product obtained in step B, add 40mL N, N-dimethylformamide, stir to make it uniformly dispersed; then add 0.7mmol sodium molybdate (Na 2 MoO 4 ), stirred until completely dissolved;

[0059] D. Add 2mmol of selenium powder into 3mL of hydrazine hydrate, stir until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com