Bi1/2Na1/2TiO3 high-dielectric ceramic capacitor material with high-temperature stability and preparation method of Bi1/2Na1/2TiO3 high-dielectric ceramic capacitor material

A ceramic capacitor and sodium bismuth titanate-based technology are applied in the field of high dielectric ceramic capacitor materials and their preparation, which can solve the problems of low dielectric permittivity and difficulty in extending the working temperature range, and achieve a simple preparation method, excellent performance and good performance. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

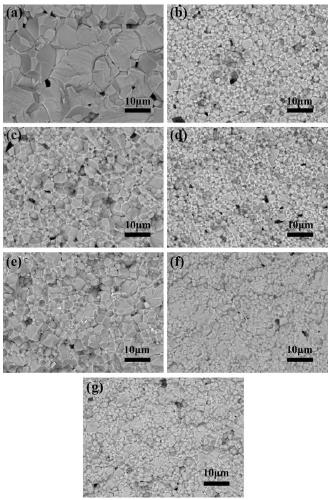

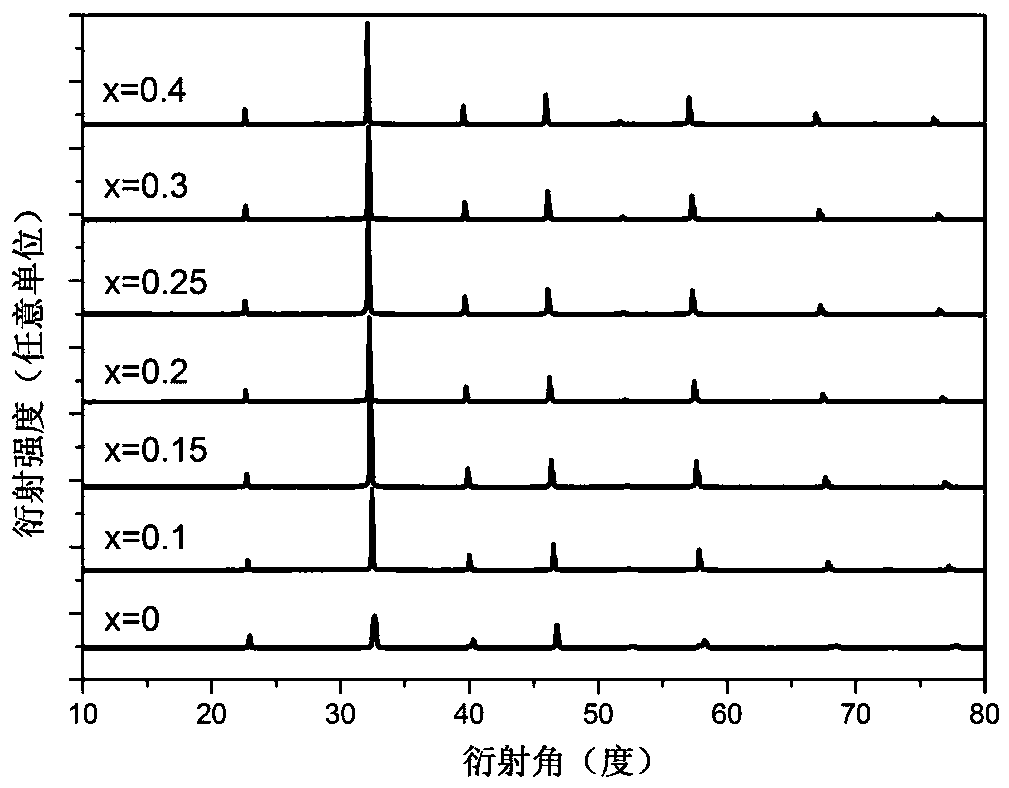

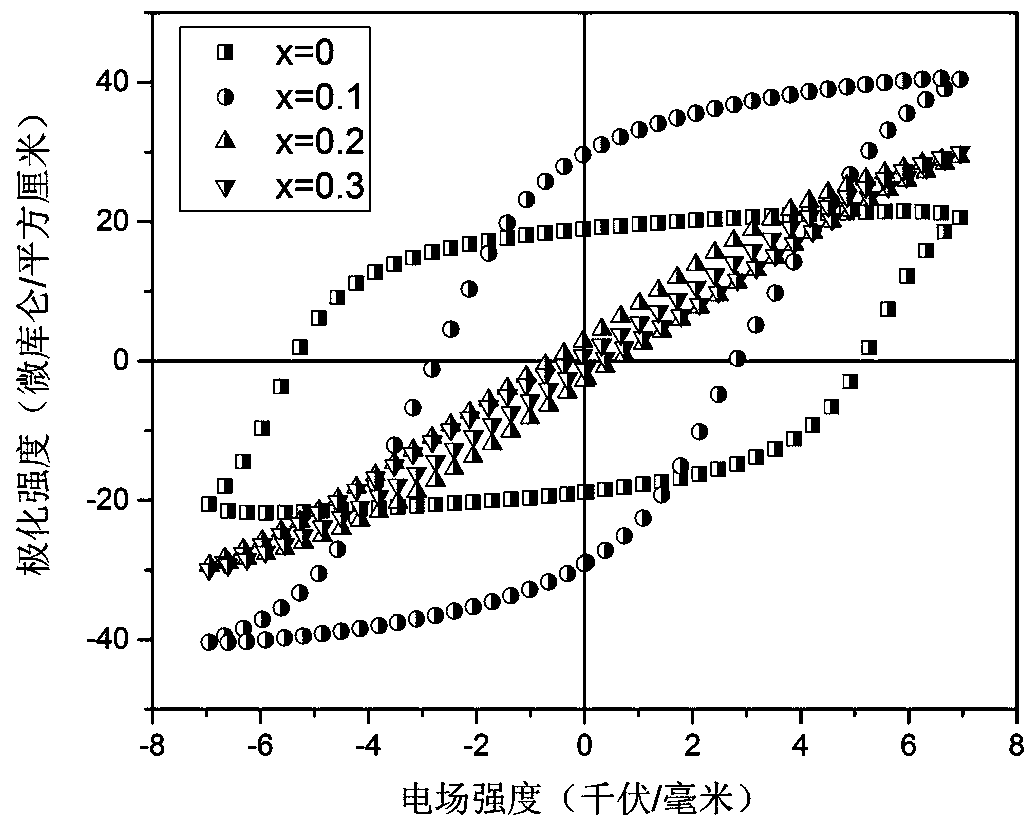

Embodiment 1

[0043] 1) According to the chemical composition (1-x)Bi 1 / 2 Na 1 / 2 TiO 3 -xPbMg 1 / 3 Nb 2 / 3 o 3 , x = 0.1 in the metal atom molar ratio and take into account the purity of the raw materials and weigh Bi respectively 2 o 3 , NaHCO 3 、TiO 2 , Pb 3 o 4 , Nb 2 o 5 And basic magnesium carbonate as raw material;

[0044] 2) The weighed Bi 2 o 3 , NaHCO 3 、TiO 2 , Pb 3 o 4 , Nb 2 o 5 Mix it with basic magnesium carbonate and put it in a nylon ball mill tank, use absolute ethanol as the medium, mix it with zirconia balls for 24 hours, the ratio of solid to liquid balls is 1:2:4, and pass through a 40-mesh sieve after drying at 80°C , the briquette was heated to 800°C for high-temperature calcination synthesis, kept for 2 hours, and the heating rate was 2°C / min;

[0045] 3) Grind 100 g of the powder synthesized in step (2), mix and mill it with zirconia balls for 48 h, dry it at 80° C. and grind it into powder, and select 6 g of 7 wt % polyvinyl alcohol aqueous solu...

Embodiment 2

[0047] 1) According to the chemical composition (1-x)Bi 1 / 2 Na 1 / 2 TiO 3 -xPbMg 1 / 3 Nb 2 / 3 o 3 , x = 0.3 metal atom molar ratio and take Bi by weighing respectively after considering raw material purity 2 o 3 , NaHCO 3 、TiO 2 , Pb 3 o 4 , Nb 2 o 5 And basic magnesium carbonate as raw material;

[0048] 2) The weighed Bi 2 o 3 , NaHCO 3 、TiO 2 , Pb 3 o 4 , Nb 2 o 5 Mix it with basic magnesium carbonate and put it in a nylon ball mill tank, use absolute ethanol as the medium, mix it with zirconia balls for 24 hours, the ratio of solid to liquid balls is 1:2:4, and pass through a 40-mesh sieve after drying at 80°C , the briquette was heated to 800°C for high-temperature calcination synthesis, kept for 2 hours, and the heating rate was 2°C / min;

[0049] 3) Grind 100 g of the powder synthesized in step (2), mix and mill it with zirconia balls for 48 h, dry it at 80° C. and grind it into powder, and select 6 g of 7 wt % polyvinyl alcohol aqueous solution as the ...

Embodiment 3

[0051] 1) According to the chemical composition (1-x)Bi 1 / 2 Na 1 / 2 TiO 3 -xPbMg 1 / 3 Nb 2 / 3 o 3 , x = 0.2 metal atom molar ratio and take Bi by weighing respectively after considering raw material purity 2 o 3 , NaHCO 3 、TiO 2 , Pb 3 o 4 , Nb 2 o 5 And basic magnesium carbonate as raw material;

[0052] 2) The weighed Bi 2 o 3 , NaHCO 3 、TiO 2 , Pb 3 o 4 , Nb 2 o 5 Mix it with basic magnesium carbonate and put it in a nylon ball mill tank, use absolute ethanol as the medium, mix it with zirconia balls for 24 hours, the ratio of solid to liquid balls is 1:2:4, and pass through a 40-mesh sieve after drying at 80°C , the briquette was heated to 800°C for high-temperature calcination synthesis, kept for 2 hours, and the heating rate was 2°C / min;

[0053] 3) Grind 100 g of the powder synthesized in step (2), mix and mill it with zirconia balls for 48 h, dry it at 80° C. and grind it into powder, and select 6 g of 7 wt % polyvinyl alcohol aqueous solution as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com