New energy automobile charging buckled cover assembling equipment

A new energy vehicle and assembly equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems affecting product quality, product surface scratches, irregular shape of charging button cover, etc., to achieve convenient screw fixing , Improve work efficiency and avoid scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

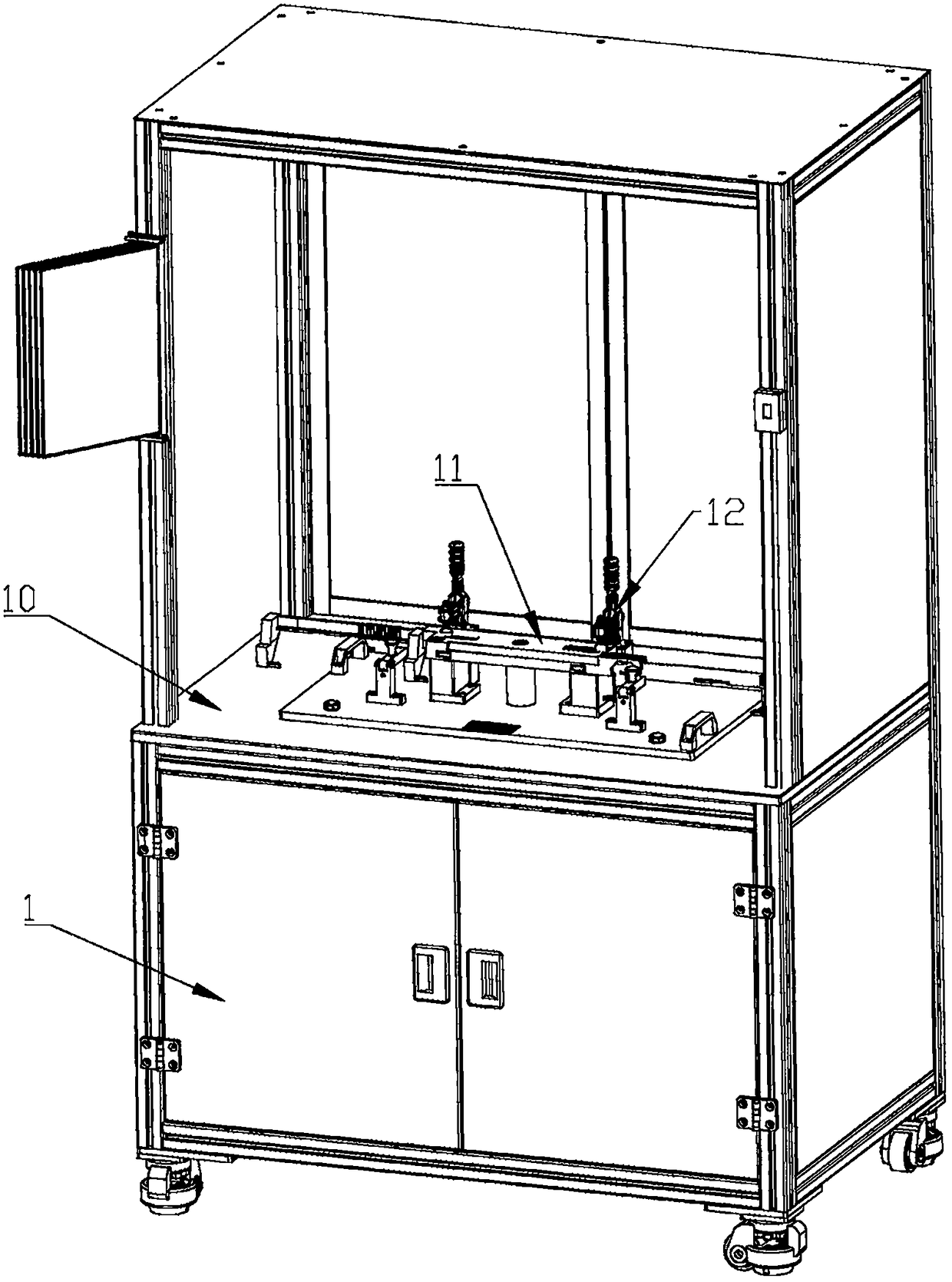

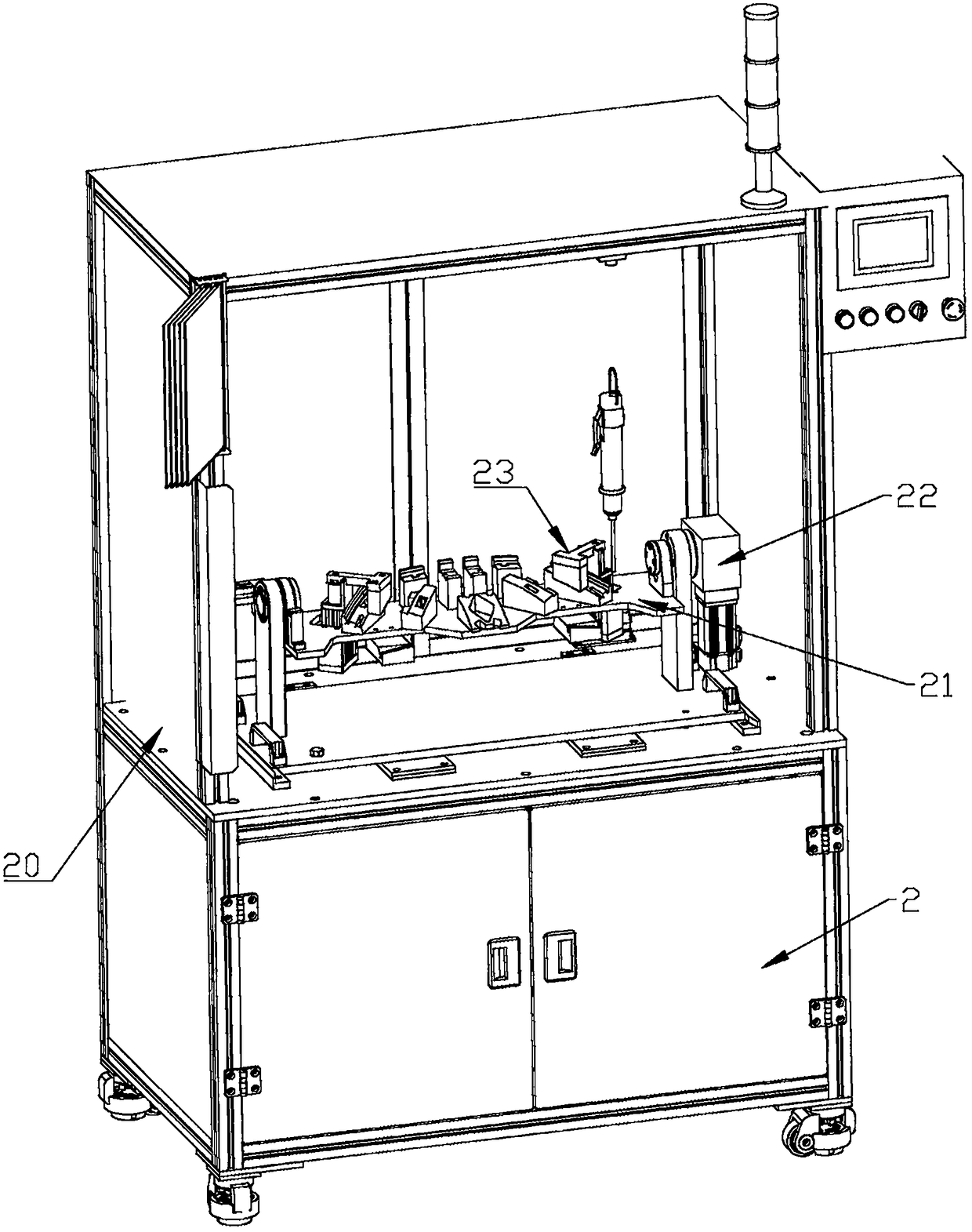

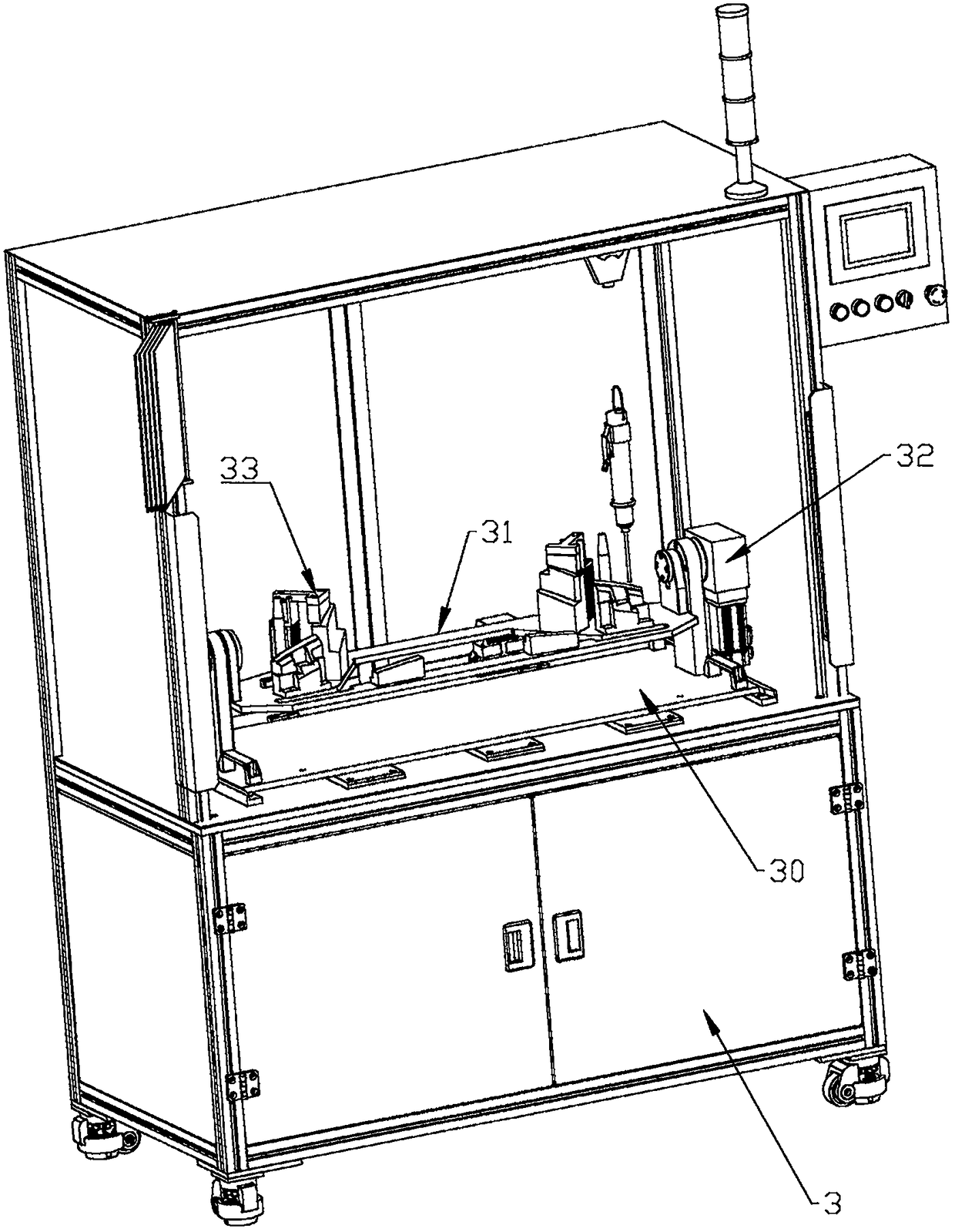

[0022] Such as Figure 1-5 As shown, a new energy vehicle charging buckle cover assembly equipment includes: lock body assembly installation platform 1, outer cover bright strip installation platform 2, bright strip lock body installation platform 3, outer panel hinge installation platform 4, charging buckle Cover installation platform 5; the lock body assembly installation platform 1, the outer cover plate bright strip installation platform 2, the bright strip lock body installation platform 3, the outer panel hinge installation platform 4, and the charging buckle cover installation platform 5 form a charging buckle cover assembly assembly line; the lock body assembly mounting platform 1 is equipped with a lock body; the outer cover is placed on the outer cover bright strip installation platform 2, and the bright strip and the outer cover are assembled through the outer cover bright strip installation platform 2 Turn over and screw to form the bright strip of the outer cover;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com