Composite boards and panels

A technology of core board and building board, applied in the field of building board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

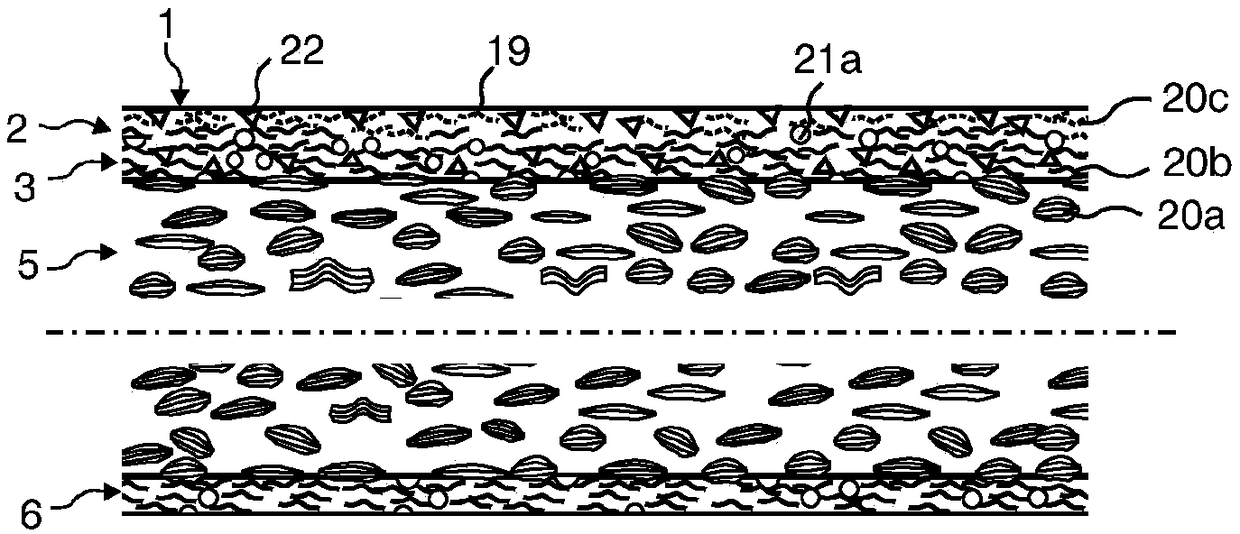

[0185] 48% by weight of wood particles and dry fibers from spruce with a moisture content of about 1% and sieved through a 400 micron screen, with 48% by weight of PVC particles (Vestolit 1353) with an average size of 60 microns and 4% by weight of gray pigment Mixing such that a dry blend of wood particles in powder form and thermoplastic particles in powder form is obtained. Thereafter the dry blend was applied as a 12mm thick powder layer onto a 0.6mm aluminum panel, preheated to 100°C in a hot air oven and fed into a hydraulic press. The dry blend was squeezed under heating at 160° C. with a pressure of 10 bar within 2 minutes and allowed to cool. When the temperature reached 80°C, the press was turned on. Flat rigid 4 mm gray wood plastic particle (WPP) panels were obtained at room temperature.

[0186] 200g / m 2 A balanced layer of powder containing a mixture of 35% by weight of melamine, 35% by weight of wood fibers and 30% by weight of PVC powder (Vestolit 1353) was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com