Preparation method of high-purity strontium hydroxide

A strontium hydroxide, high-purity technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, can solve the problem of low purity of strontium hydroxide products, and achieve the effects of reducing carbonization, improving calcination efficiency and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

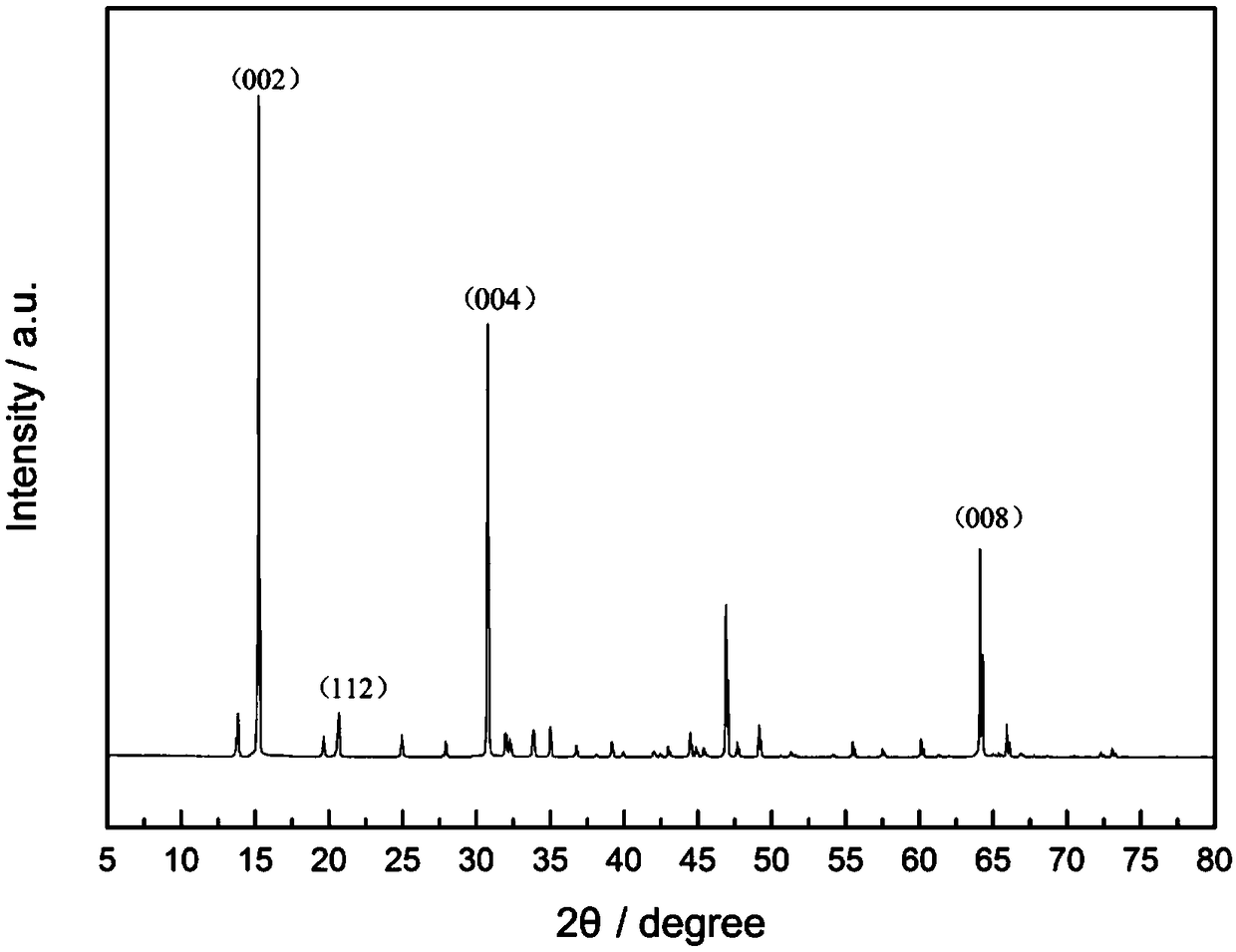

Image

Examples

preparation example Construction

[0030] The preparation method of high-purity strontium hydroxide of the present invention comprises the following steps:

[0031] In step S1, industrial strontium carbonate is calcined by a microwave calcining method to obtain a calcined product.

[0032] Preferably, in this step, the calcination temperature is 1250°C-1350°C, and the calcination time is 10min-30min. Microwave heating can achieve the effect of rapid calcination, and the time required is a fraction or even a tenth of the heating time of muffle furnaces, electric furnaces, tunnel kilns, lifting kilns, rotary kilns and other equipment.

[0033] In step S2, the calcined product is soaked in water and subjected to hot filtration to obtain a first hot solution of strontium hydroxide.

[0034] Preferably, in this step, the calcined product is soaked in water according to a solid-to-liquid ratio of 1:5 to 1:10; that is, for every 1 mass part of the calcined product, 5 to 10 mass parts of water are used for water immer...

Embodiment 1

[0049] The first step is calcining strontium carbonate.

[0050] Specifically, 200 g of industrial strontium carbonate was weighed, placed in a microwave calciner, heated to 1250° C. for 15 min, and kept at a temperature of 30 min to obtain 140.5 g of a calcined product.

[0051] In the second step, crude strontium hydroxide is prepared.

[0052]Specifically, the calcined product is immersed in 702.5g of water, heated to boiling and kept for 10 minutes to obtain the first slurry; the first slurry is filtered while it is hot to obtain the first hot solution of strontium hydroxide, and the solution is cooled to 5°C, solid-liquid separation to obtain aqueous crude strontium hydroxide octahydrate crystals; place the crystals in a blast drying oven, and dry at 50°C for 30 minutes to obtain 325 g of crude strontium hydroxide.

[0053] In the obtained crude strontium hydroxide, the content of strontium hydroxide octahydrate is 98.93%.

[0054] The third step is to prepare high-puri...

Embodiment 2

[0058] The first step is calcining strontium carbonate.

[0059] Specifically, 200 g of industrial strontium carbonate was weighed, placed in a microwave calciner, heated to 1280° C. for 15 minutes, and kept for 25 minutes to obtain 141.5 g of calcined products.

[0060] In the second step, crude strontium hydroxide is prepared.

[0061] Specifically, the calcined product is immersed in 849g of water, heated to boiling and kept for 15 minutes to obtain the first slurry; the first slurry is filtered while it is hot to obtain the first hot solution of strontium hydroxide, and the solution is cooled to 10 °C; solid-liquid separation to obtain aqueous crude strontium hydroxide octahydrate crystals; place the crystals in a blast drying oven and dry at 50 °C for 30 minutes to obtain 306 g of crude strontium hydroxide.

[0062] In the obtained crude strontium hydroxide, the content of strontium hydroxide octahydrate is 99.01%.

[0063] The third step is to prepare high-purity stron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com