A common treatment method for low-cobalt and high-manganese waste materials and waste lithium battery cathode materials

A technology for waste lithium batteries and cathode materials, which is applied in the field of regeneration of cathode materials of nickel-cobalt-manganese ternary lithium batteries, can solve the problems of high cost and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

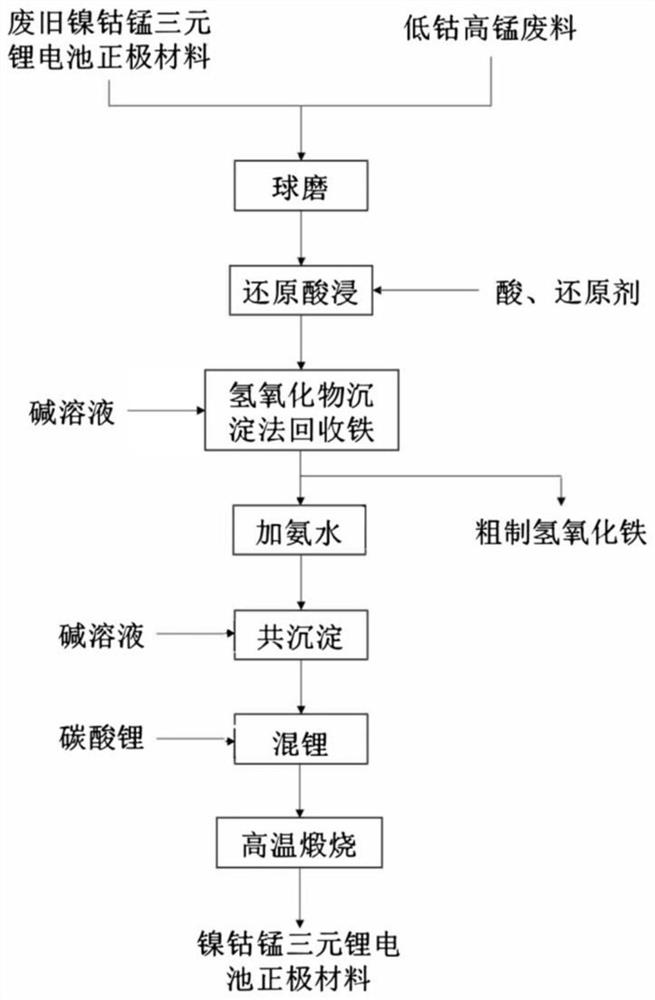

[0025] refer to figure 1 , figure 1 It shows a process flow chart of co-processing low-cobalt high-manganese waste materials and waste lithium battery cathode materials according to an embodiment of the present invention.

[0026] Mix the low-cobalt and high-manganese waste with the positive electrode material of the waste lithium battery, ball mill it for 0.5h, and then use acid and reducing agent to leach to obtain the first mixed solution, wherein the acid used is sulfuric acid, the reducing agent is hydrogen peroxide, and the leaching temperature is 45°C. The leaching time is 0.5 h, the acid concentration is 0.5 mol / L; the first mixed solution is heated in a water bath and suction filtered to obtain the second mixed solution, and sodium hydroxide solution is added to the second mixed solution to adjust the pH to 4 to obtain crude hydrogen Iron oxide precipitation and the third mixed solution, wherein the temperature of the water bath heating is 50°C, and the heating time ...

Embodiment 2

[0029] Mix the low-cobalt and high-manganese waste material with the positive electrode material of the waste lithium battery, ball mill it for 1 hour, and then use acid and reducing agent to leaching to obtain the first mixed solution, wherein the acid used is nitric acid, the reducing agent is ascorbic acid, the leaching temperature is 65°C, and the leaching The time is 2.5 hours, the acid concentration is 2mol / L; the first mixed solution is heated in a water bath and suction filtered to obtain the second mixed solution, and sodium hydroxide solution is added to the second mixed solution to adjust the pH to 4.5 to obtain crude ferric hydroxide Precipitation and the third mixed solution, wherein the temperature of the water bath heating is 70°C, and the heating time is 3h; add manganese, nickel, cobalt nitrate solution to the third mixed solution to adjust the ion ratio, so that the nickel, cobalt, and manganese ion moles The concentration ratio is 1:1:1, adding ammonia water ...

Embodiment 3

[0031] Mix the low-cobalt and high-manganese waste with the positive electrode material of the waste lithium battery, ball mill for 2 hours, and then use acid and reducing agent to leaching to obtain the first mixed solution, wherein the acid used is hydrochloric acid, the reducing agent is glucose, the leaching temperature is 95°C, and the leaching The time is 5 hours, the acid concentration is 4mol / L; the first mixed solution is heated in a water bath and suction filtered to obtain the second mixed solution, and sodium hydroxide solution is added to the second mixed solution to adjust the pH to 5 to obtain crude ferric hydroxide precipitate And the third mixed solution, wherein the temperature of the water bath heating is 90 ℃, and the heating time is 3h; Add the chloride salt solution of manganese, nickel, cobalt to the third mixed solution to adjust the ion ratio, so that the nickel, cobalt, manganese ion moles The concentration ratio is 1:1:1, add ammonia water and continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com