Catalyst for producing fuel oil by catalytically cracking waste plastics and preparation method thereof

A catalytic cracking, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low efficiency of plastic decomposition, lack of catalyst, selectivity It can achieve the effect of small loss of transition metal, high catalytic efficiency and high decomposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Titanium-based catalyst (Ti)

[0037](1) Pretreatment: Grind 10g of the clay raw material to an average size of no more than 30 meshes, and select bentonite from Sigma-Aldrich (USA) as the raw material of the clay structure;

[0038] (2) Preparation of homogeneous clay suspension: the clay obtained in step (1) is mixed with deionized water under stirring to prepare homogeneous clay suspension;

[0039] (3) Preparation of intercalation solution: mix 0.1mol / L sodium hydroxide alkaline solution as an activator with 2g titanium chloride, control the pH of the mixed solution to 4, and age the solution at a specific temperature for 4h after mixing Achieve balance;

[0040] (4) Intercalation: Under stirring conditions, the intercalation solution prepared in step (3) is added dropwise to the homogeneous clay suspension obtained in step (2), the dropping temperature is controlled at 80°C, and the dropping time is controlled at 15 hours;

[0041] (5) Aging and wa...

Embodiment 2

[0045] Embodiment 2: zirconium-based catalyst (Zr)

[0046] (1) Pretreatment: Grind 10g of the clay raw material to an average size of no more than 30 meshes, and select bentonite from Sigma-Aldrich (USA) as the raw material of the clay structure;

[0047] (2) Preparation of homogeneous clay suspension: the clay obtained in step (1) is mixed with deionized water under stirring to prepare homogeneous clay suspension;

[0048] (3) Preparation of intercalation solution: 0.1mol / L sodium hydroxide alkaline solution is mixed with 2g zirconium chloride as an activator, the pH of the mixed solution is controlled to be 4, after mixing, the solution is aged at a specific temperature for a period of time time to balance;

[0049] (4) Intercalation: adding the intercalation solution prepared in step (3) dropwise to the homogeneous clay suspension obtained in step (2), the dropping temperature is controlled at 80°C, and the dropping time is controlled at 15 hours;

[0050] (5) Aging and ...

Embodiment 3

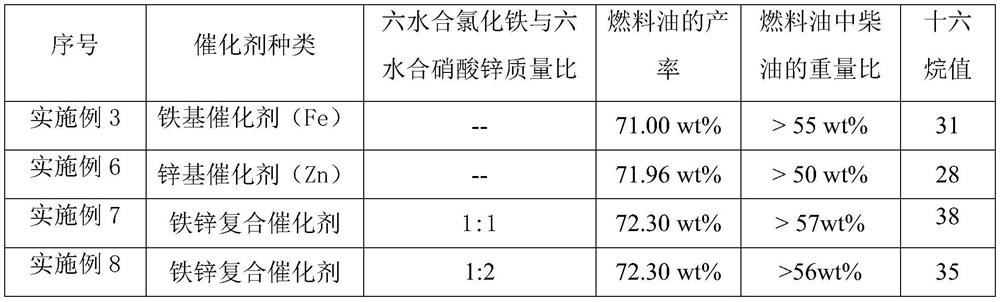

[0054] Embodiment 3: Iron-based catalyst (Fe)

[0055] (1) Pretreatment: Grind 10g of the clay raw material to an average size of no more than 30 meshes, and select bentonite from Sigma-Aldrich (USA) as the raw material of the clay structure;

[0056] (2) Preparation of homogeneous clay suspension: the clay obtained in step (1) is mixed with deionized water under stirring to prepare homogeneous clay suspension;

[0057] (3) Preparation of intercalation solution: 0.1mol / L sodium hydroxide alkaline solution is mixed with 4g ferric chloride hexahydrate as an activator, the pH of the mixed solution is controlled to be 4, after mixing, the solution is kept at a specific temperature Aging for a period of time to reach equilibrium;

[0058] (4) Intercalation: adding the intercalation solution prepared in step (3) dropwise to the homogeneous clay suspension obtained in step (2), the dropping temperature is controlled at 80°C, and the dropping time is controlled at 15 hours;

[0059]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com