A kind of rice bran oil refining method

A technology of rice bran oil and rice bran, applied in the field of rice bran oil refining, to achieve the effects of accelerating the crystallization process, increasing the content, improving refining efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

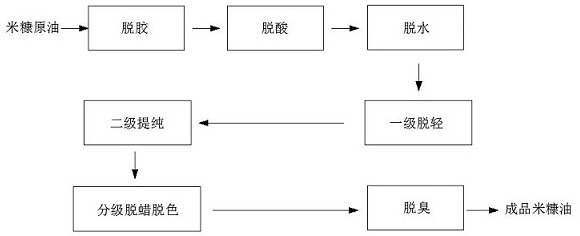

Image

Examples

Embodiment 1

[0028] The present embodiment provides a method for refining rice bran oil, comprising the following steps:

[0029] 1) Phosphoric acid degumming

[0030] Heat the crude rice bran to 50°C, add 0.08% phosphoric acid (concentration of 80%) to the oil, stir and heat to 65°C, stop heating, and continue stirring for 15 minutes to obtain degummed oil.

[0031] 2) Alkali refining and deacidification

[0032] Add the alkaline solution with a temperature of 60°C and a concentration of 13°Bé, stir and heat to 85°C, react for 15 minutes, and then remove the soapstock by centrifugation to obtain a deacidified oil.

[0033] 3) Flash dehydration

[0034] The above-mentioned deacidified oil is transported to a flash tower for one flash evaporation to remove part of the water to obtain dehydrated oil.

[0035] 4) Level 1 lightening

[0036] The dehydrated oil is transported to the preheater through the feed pump and preheated to a preheating temperature of 190°C. After that, the preheate...

Embodiment 2

[0048]The present embodiment provides a method for refining rice bran oil, comprising the following steps:

[0049] 1) Phosphoric acid degumming

[0050] Heat the crude rice bran to 45°C, add 0.07% phosphoric acid (75% concentration) to the oil, stir and heat to 60°C, stop heating, and continue stirring for 10 min to obtain degummed oil.

[0051] 2) Alkali refining and deacidification

[0052] Add the lye solution with a temperature of 55°C and a concentration of 12°Bé, stir and heat to 80°C, react for 10 minutes, and then remove the soapstock by centrifugation to obtain a deacidified oil.

[0053] 3) Flash dehydration

[0054] The above-mentioned deacidified oil is transported to a flash tower for one flash evaporation to remove part of the water to obtain dehydrated oil.

[0055] 4) Level 1 lightening

[0056] The dehydrated oil is transported to the preheater through the feed pump and preheated to a preheating temperature of 180°C. After that, the preheated dehydrated ...

Embodiment 3

[0068] The present embodiment provides a method for refining rice bran oil, comprising the following steps:

[0069] 1) Phosphoric acid degumming

[0070] Heat the crude rice bran to 55°C, add 0.10% phosphoric acid (85% concentration) to the oil, stir and heat to 70°C, stop heating, and continue stirring for 20 minutes to obtain degummed oil.

[0071] 2) Alkali refining and deacidification

[0072] Add the alkaline solution with a temperature of 65°C and a concentration of 15°Bé, stir and heat to 90°C, react for 20 minutes, and then remove the soapstock by centrifugation to obtain a deacidified oil.

[0073] 3) Flash dehydration

[0074] The above-mentioned deacidified oil is transported to a flash tower for one flash evaporation to remove part of the water to obtain dehydrated oil.

[0075] 4) Level 1 lightening

[0076] The dehydrated oil is transported to the preheater through the feed pump and preheated to a preheating temperature of 200°C. After that, the preheated d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com