Production process of thick-layer asphalt waterproof roll

A kind of asphalt waterproof membrane and production process technology, applied in the direction of layered products, lamination, lamination device, etc., can solve the problems of increasing the production cost of the membrane, large area of coating tank, complex production process, etc., to achieve The effect of material saving, low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

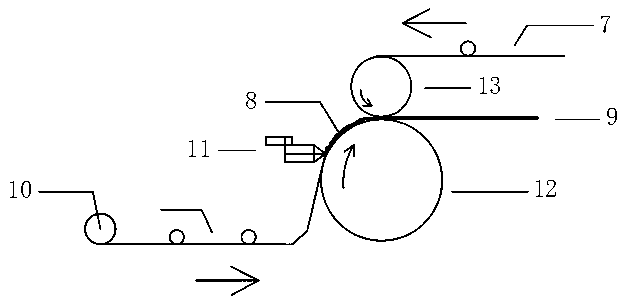

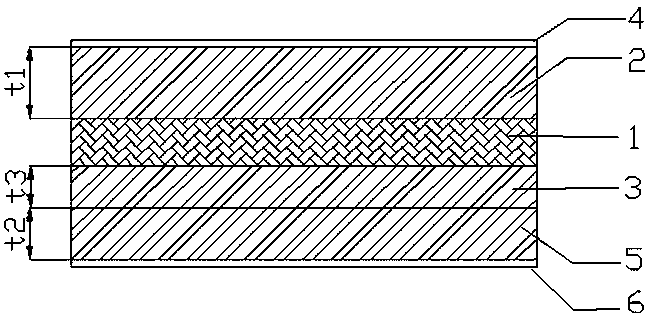

[0030] A production process of thick-layer asphalt waterproof membrane, such as figure 1 , 2 It includes the following steps:

[0031] S1 Preparation of the main body layer 7: After pre-soaking the tire base 1 in a dipping tank, squeeze it dry, cool it, and then put it into the coating tank with coating material, adjust the height position of the tire base 1, and make it through the coating roll The coating material is respectively coated on the upper surface and the lower surface of the tire base 1, so that the upper surface of the tire base 1 forms an upper surface coating layer 2 with a thickness of t1, and the lower surface of the tire base 1 forms a first lower surface with a thickness of t3. The surface is coated with a cover layer 3, and t3 is less than t1, and then the cover layer 2 is coated on the upper surface with a cover layer film 4 to obtain the main body layer 7;

[0032] S2 Preparation of the lower layer 8: the unwinding mechanism 10 releases the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap