Method for preparing anti-aging cable sheath

A cable sheath and anti-aging technology, applied to rubber insulators, organic insulators, etc., can solve the problems of workers' health, dust pollution, and low density of white carbon black, etc., to improve insulation and high temperature resistance , low cost, comprehensive performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

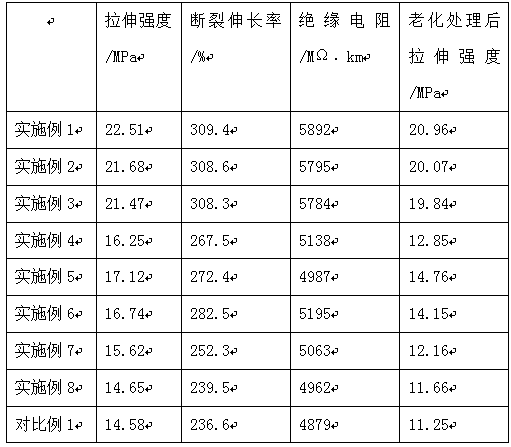

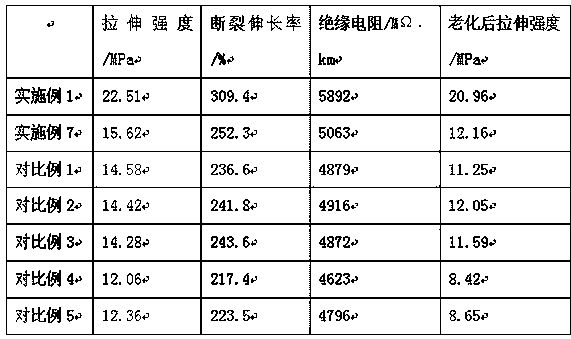

Examples

Embodiment 1

[0035] A preparation method for an aging-resistant cable sheath, comprising the following steps:

[0036] (1) Mix styrene-butadiene rubber, butadiene rubber, and chlorinated polyethylene at a temperature of 95-102°C for 1-2 minutes, then add silicon micropowder, carbon black, epoxy soybean oil, and anti-aging agent AW, nano titanium dioxide, attapulgite, chlorinated paraffin, magnesium spinel, mixed for 150s;

[0037] (2) Add sulfur and tetramethylthiuram disulfide to the rubber treated in step (1) for vulcanization treatment, the vulcanization temperature is 163-168°C, and the vulcanization time is 62s;

[0038] (3) Extrude the rubber material processed in step (2) with an extruder, the length-to-diameter ratio of the extruder is 18:1, and the compression ratio is 1.72;

[0039] The weight ratio of each raw material is as follows: 78 parts of styrene-butadiene rubber, 32 parts of butadiene rubber, 92 parts of chlorinated polyethylene, 9 parts of silicon micropowder, 11 parts...

Embodiment 2

[0057] The weight ratio of each raw material is as follows: 75-80 parts of styrene-butadiene rubber, 40 parts of butadiene rubber, 92 parts of chlorinated polyethylene, 10 parts of silicon micropowder, 9 parts of carbon black, 13 parts of epoxy soybean oil, 1.9 parts of sulfur, 1.1 parts of tetramethylthiuram sulfide, 0.95 parts of anti-aging agent AW, 7.8 parts of nano-titanium dioxide, 46 parts of attapulgite, 11 parts of chlorinated paraffin, and 9.8 parts of magnesium spinel. The processing steps of each raw material are as in Example 1.

Embodiment 3

[0059] The weight ratio of each raw material is as follows: 79 parts of styrene-butadiene rubber, 36 parts of butadiene rubber, 93 parts of chlorinated polyethylene, 10 parts of silicon micropowder, 11 parts of carbon black, 14 parts of epoxy soybean oil, 2.2 parts of sulfur, tetrasulfide 1 part of methyl thiuram, 1.1 parts of anti-aging agent AW, 8 parts of nano-titanium dioxide, 48 parts of attapulgite, 10.5 parts of chlorinated paraffin, and 9 parts of magnesium spinel. The processing mode of each raw material is as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com