Manganese zirconium sulphate composite oxide catalyst as well as preparation method and application thereof

A composite oxide, sulfated manganese and zirconium technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of no catalyst technology, NOx emission reduction, etc., and achieve good medium and low temperature denitrification efficiency, good resistance to sulfur poisoning, and enhanced surface acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of sulfated manganese-zirconium composite oxide catalyst, comprising the following steps:

[0025] (1) Stir manganese acetate solution, zirconium nitrate solution and sulfuric acid solution at room temperature, then add citric acid solution, the mol ratio of the mixed solution of citric acid and zirconium nitrate and sulfuric acid is 1, obtains mixed solution;

[0026] (2) Stir and mix the mixed solution under heating in a water bath to obtain a transparent gel;

[0027] (3) drying the transparent gel to obtain a spongy solid;

[0028] (4) Grinding the spongy solid in a mortar, and then roasting in a muffle furnace to prepare the sulfated manganese-zirconium composite oxide catalyst.

[0029] Further, the concentration of the manganese acetate solution is 1-3mol / L, the concentration of the zirconium nitrate solution is 1-3mol / L, the concentration of the sulfuric acid solution is 0.8-2.4mol / L, and the concentration of the citric acid solution is 4mo...

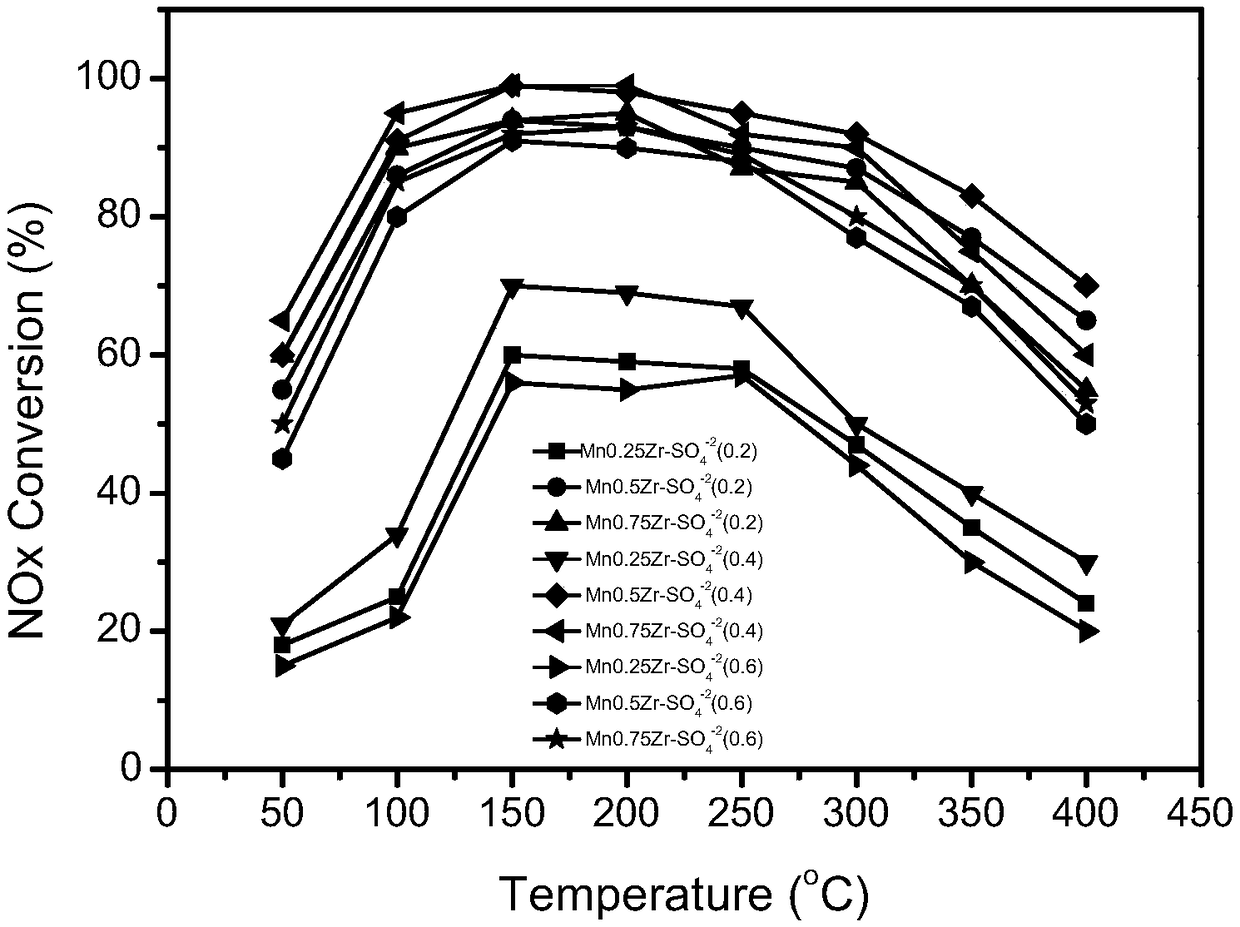

Embodiment 1

[0032] Mn0.25Zr-SO 4 2- (0.2) Preparation and application of sulfated manganese-zirconium composite oxide catalyst

[0033] (1) Stir 10ml 1mol / L manganese acetate solution, 10ml 3mol / L zirconium nitrate solution and 10ml 0.8mol / L sulfuric acid solution at room temperature for 30min, then add 10ml 4mol / L citric acid solution, citric acid and zirconium nitrate The mol ratio with manganese acetate is 1, obtains mixed solution;

[0034] (2) Stir and mix the mixed solution for 5 hours under heating in a water bath at 60°C to obtain a transparent gel;

[0035] (3) drying the transparent gel at 120°C for 24 hours to obtain a spongy solid;

[0036] (4) Grinding the spongy solid in a mortar, and then calcining in a muffle furnace at 450° C. for 4 hours to prepare a sulfated manganese-zirconium composite oxide catalyst.

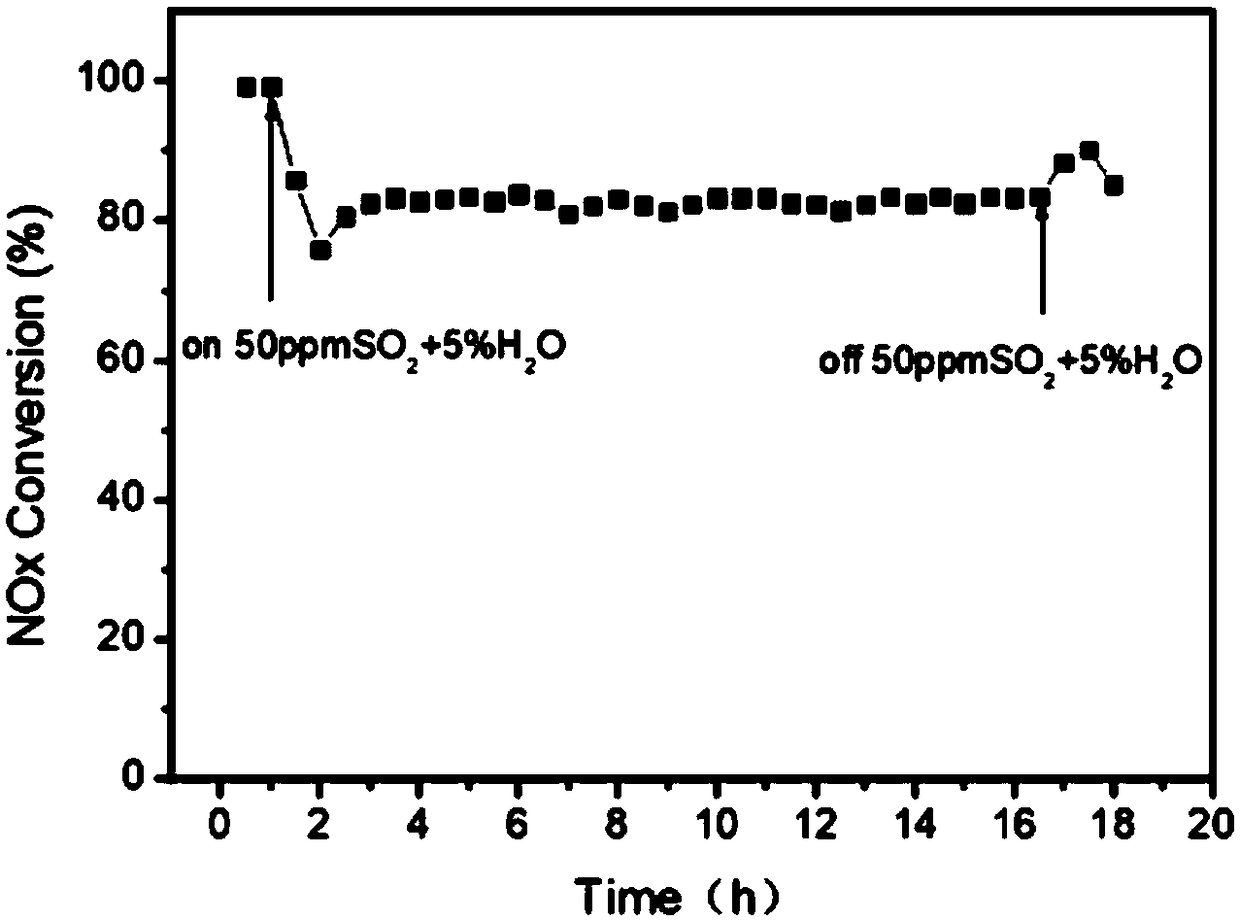

[0037] 0.12g catalyst was placed in a continuous flow fixed bed reactor, and the reaction gas composition included 0.05% NO, 0.05% NH 3 , 5% O 2 , using nitrogen...

Embodiment 2

[0039] Mn0.5Zr-SO 4 2- (0.2) Preparation and application of sulfated manganese-zirconium composite oxide catalyst

[0040] (1) Stir 10ml 2mol / L manganese acetate solution, 10ml 2mol / L zirconium nitrate solution and 10ml 0.8mol / L sulfuric acid solution at room temperature for 30min, then add 10ml 4mol / L citric acid solution, citric acid and zirconium nitrate The mol ratio with manganese acetate is 1, obtains mixed solution;

[0041] (2) Stir and mix the mixed solution for 4 hours under heating in a water bath at 70°C to obtain a transparent gel;

[0042] (3) drying the transparent gel at 120°C for 16 hours to obtain a spongy solid;

[0043] (4) Grinding the spongy solid in a mortar, and then calcining in a muffle furnace at 450° C. for 4 hours to prepare a sulfated manganese-zirconium composite oxide catalyst.

[0044] 0.12g catalyst was placed in a continuous flow fixed bed reactor, and the reaction gas composition included 0.05% NO, 0.05% NH 3 , 5% O 2 , using nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com