Automatically-processing production system and process for seat board of chair

A production system and seat board technology, applied to wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve the problems of low production efficiency, single practicability, high production cost, etc., and achieve high trimming quality and improved High work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

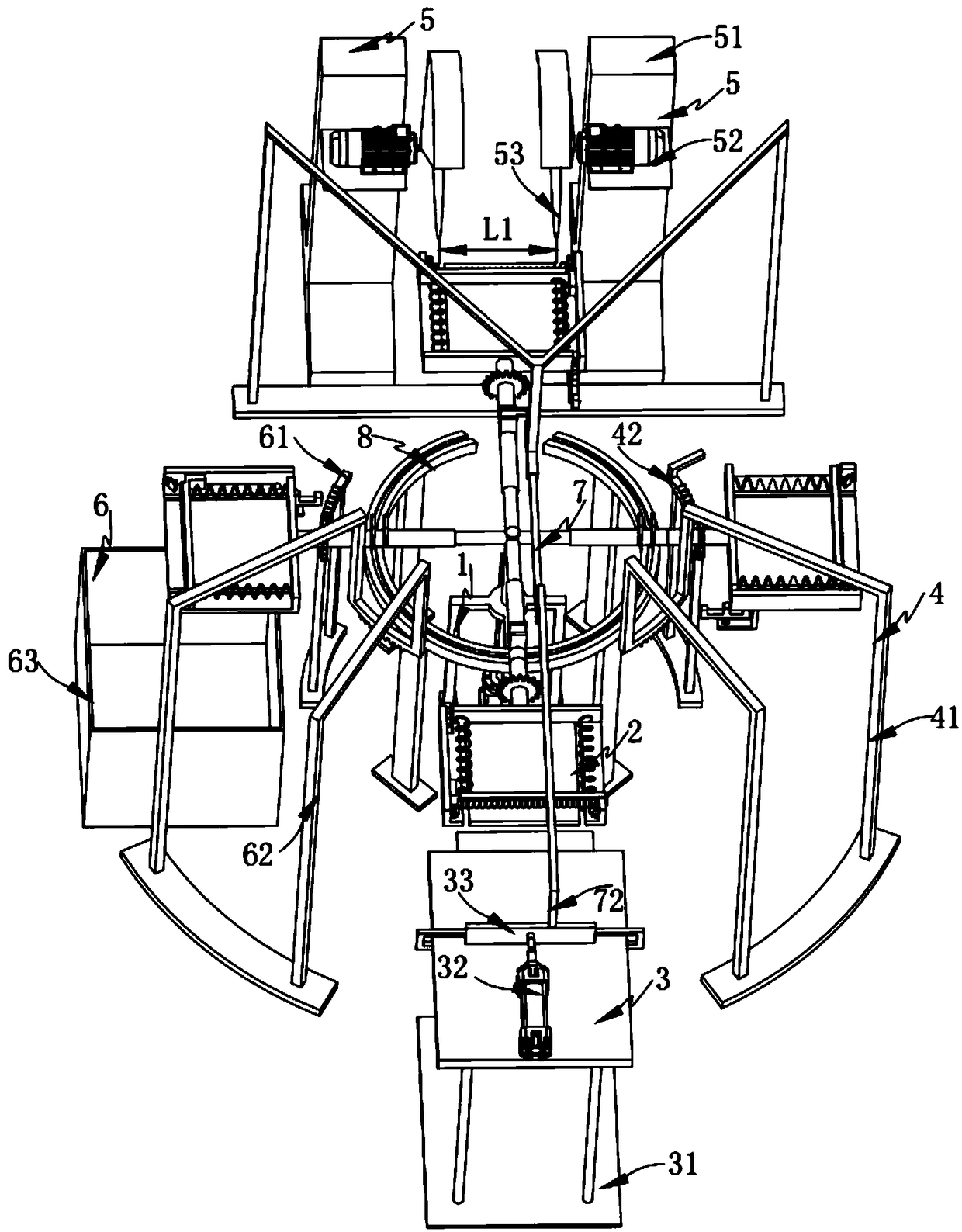

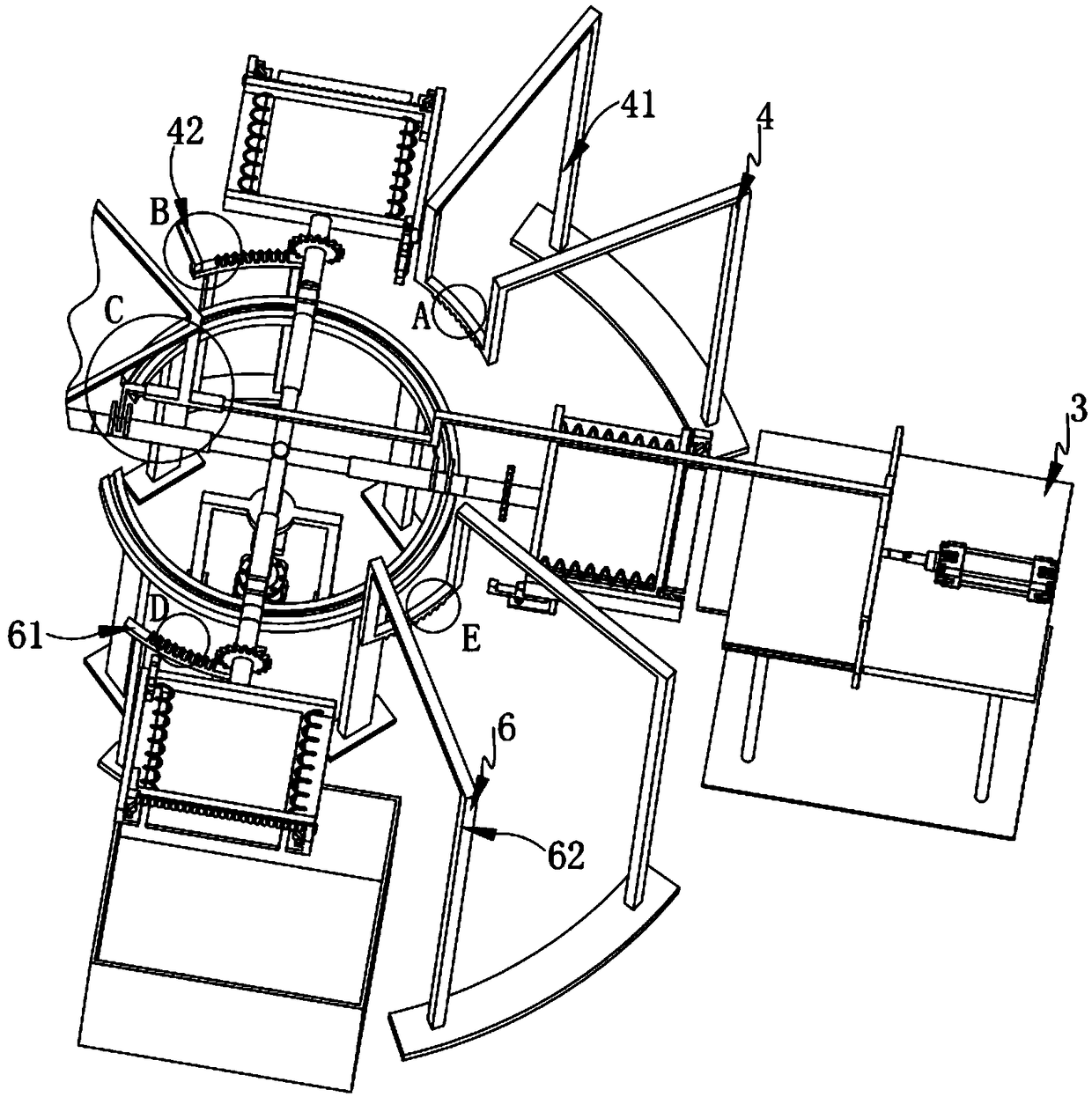

[0088] Such as figure 1 , Figure 8 , Figure 15 , Figure 16 and 17 As shown, a chair seat board automatic processing and production system includes:

[0089] A driving mechanism 1, which includes a frame 11, a rotating shaft 12 and a driving member 13;

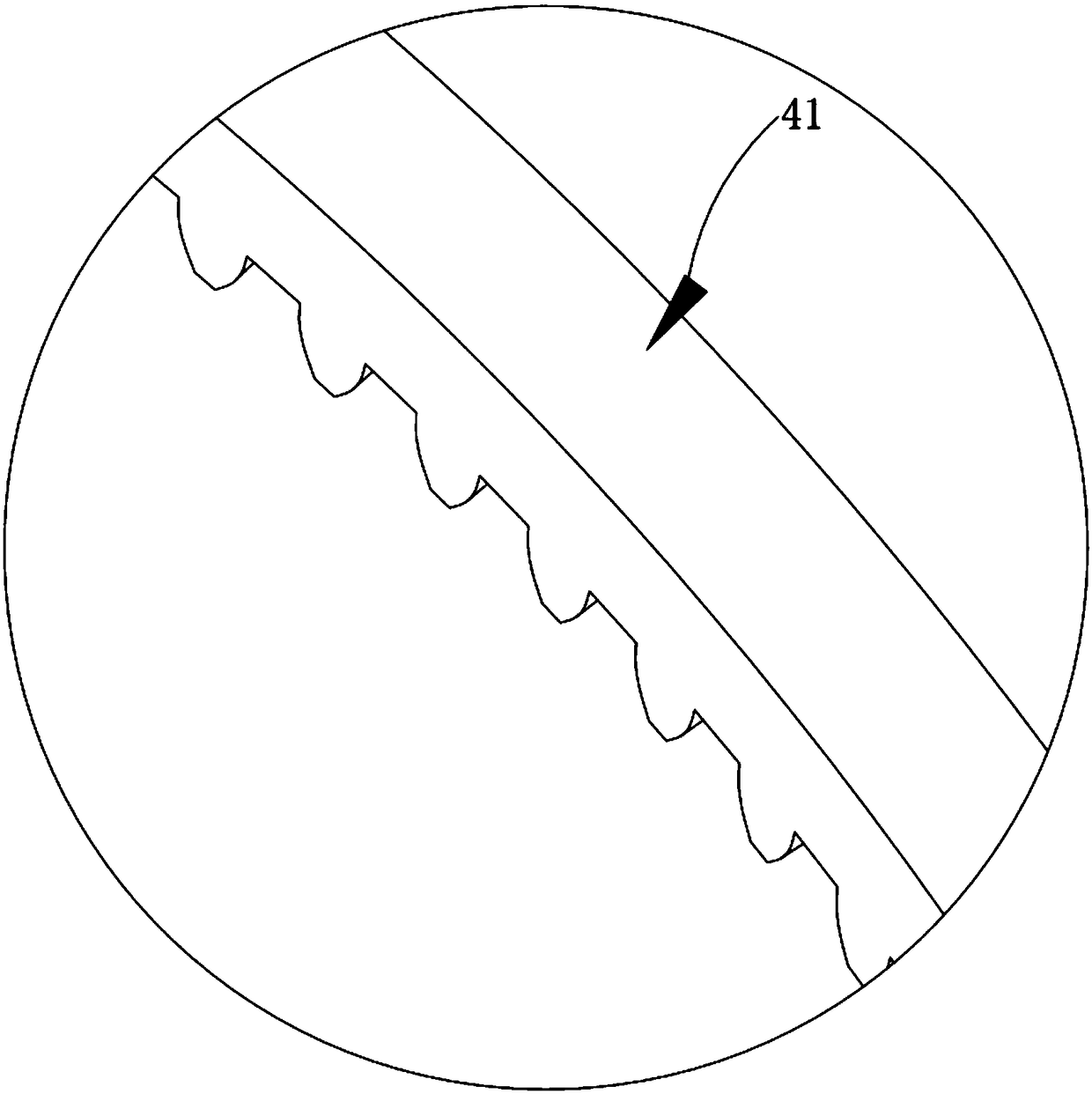

[0090] The feeding mechanism 2, the feeding mechanism 2 is fixedly arranged on the rotating shaft 12, and its number is several, the feeding mechanism 2 is arranged in an array at equal intervals along the axis of the rotating shaft 12, and it is driven by the driving mech...

Embodiment 2

[0137] Referring to the first embodiment, the second embodiment of the present invention describes a technical process of automatically trimming the edges and fixing the length of the wooden blocks used for the production of the seat board of the dining chair.

[0138] Such as Figure 18 Shown, a kind of automatic processing and production technology of chair seat board comprises the following steps:

[0139]Step 1) Loading, the cylinder 32 pushes the arranged wooden blocks onto the supporting plate 24, and due to the entry of the wooden blocks, the extrusion plate 26 is continuously squeezed and slides inward. During the sliding process, the pressing block 262 will The limit block b283 is squeezed to the bottom until the pressure block 262 moves to the bottom, and the limit block b283 pops up to block the extrusion plate 26, so that there is a certain gap between the extrusion plate 26 and the wooden block;

[0140] Step 2) conveying, the feeding mechanism 2 is driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com