Paired roller type crushing equipment for building construction

A crushing equipment and building construction technology, applied in the field of crushers and construction equipment, can solve problems such as single structure, poor functionality, poor practicability, etc., and achieve the effect of strong practicality of selection and good comprehensive performance of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

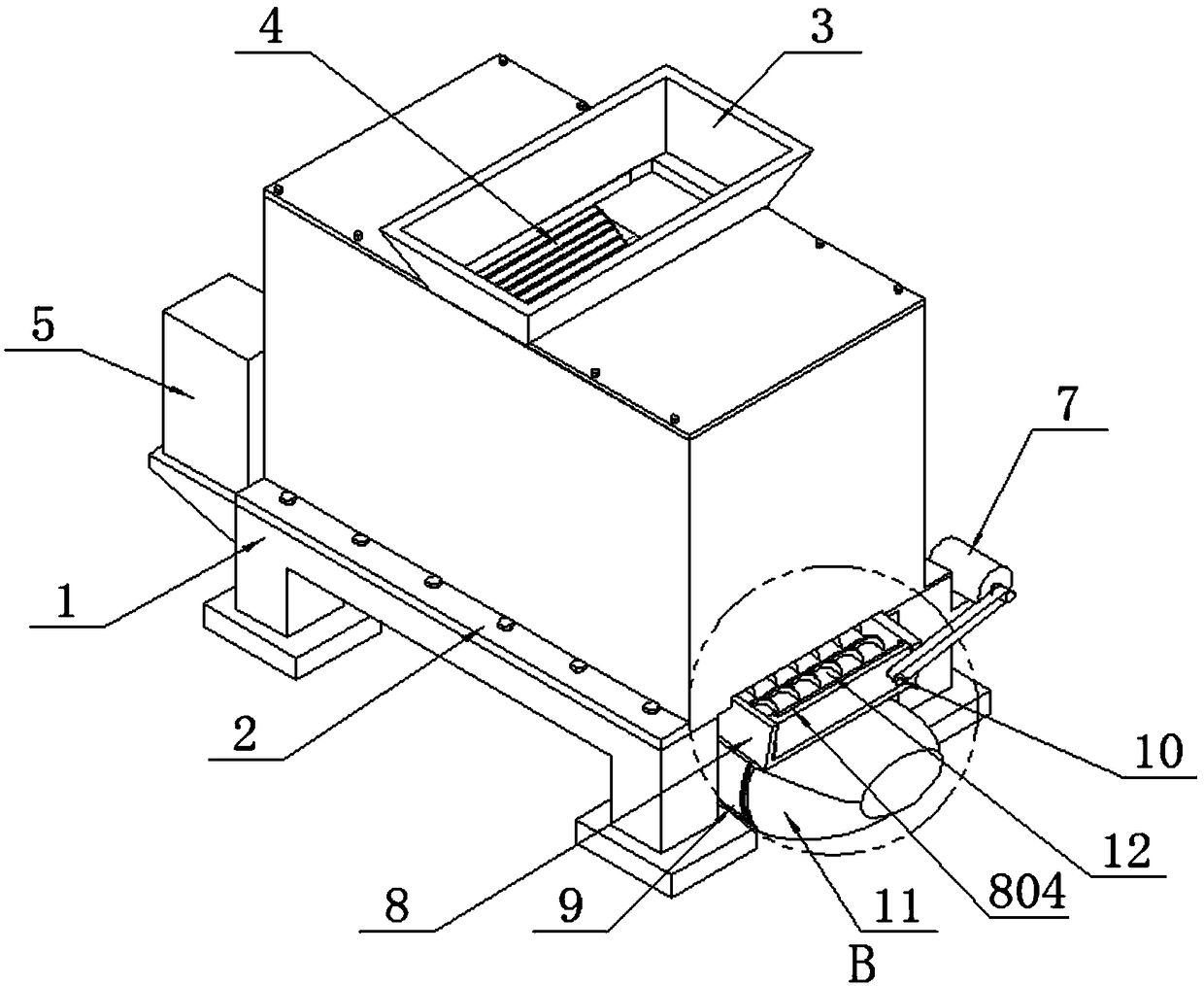

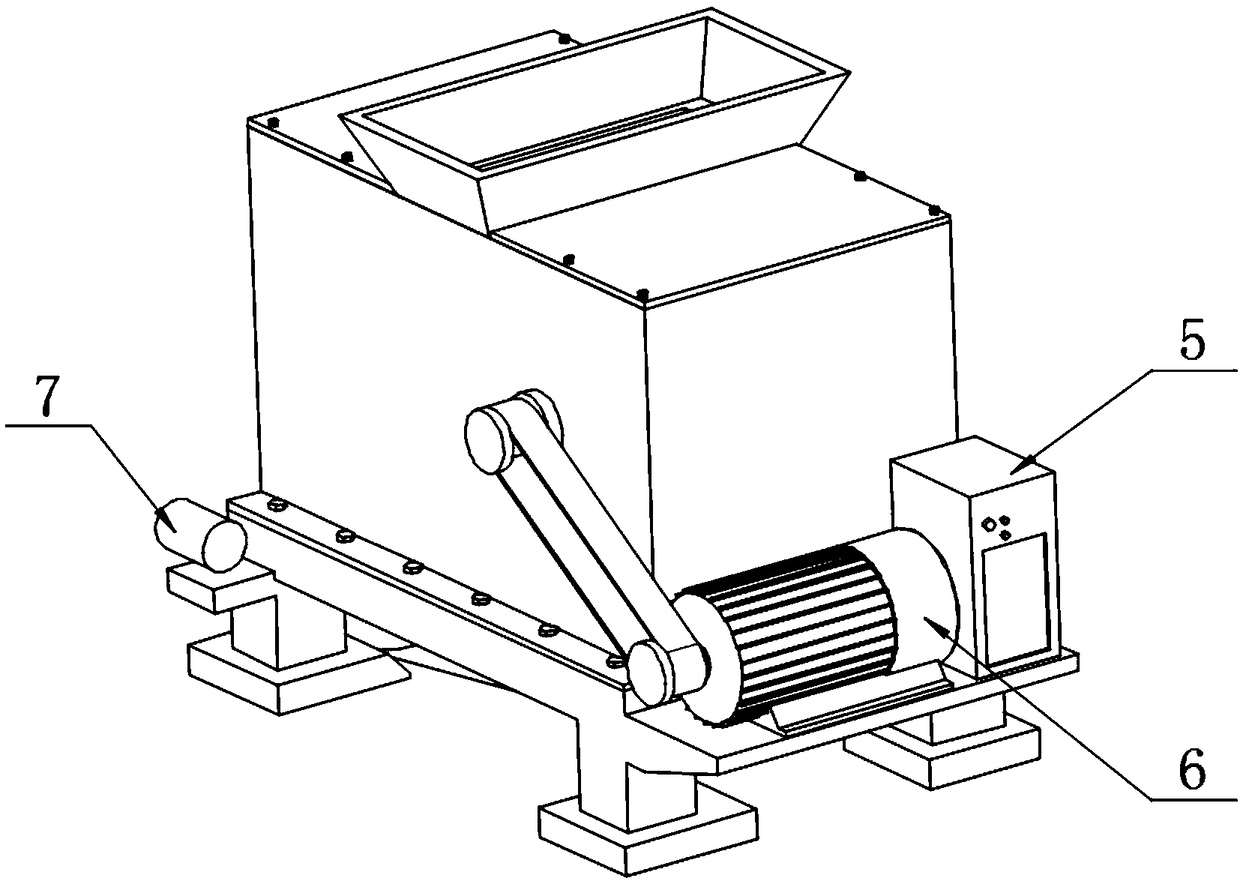

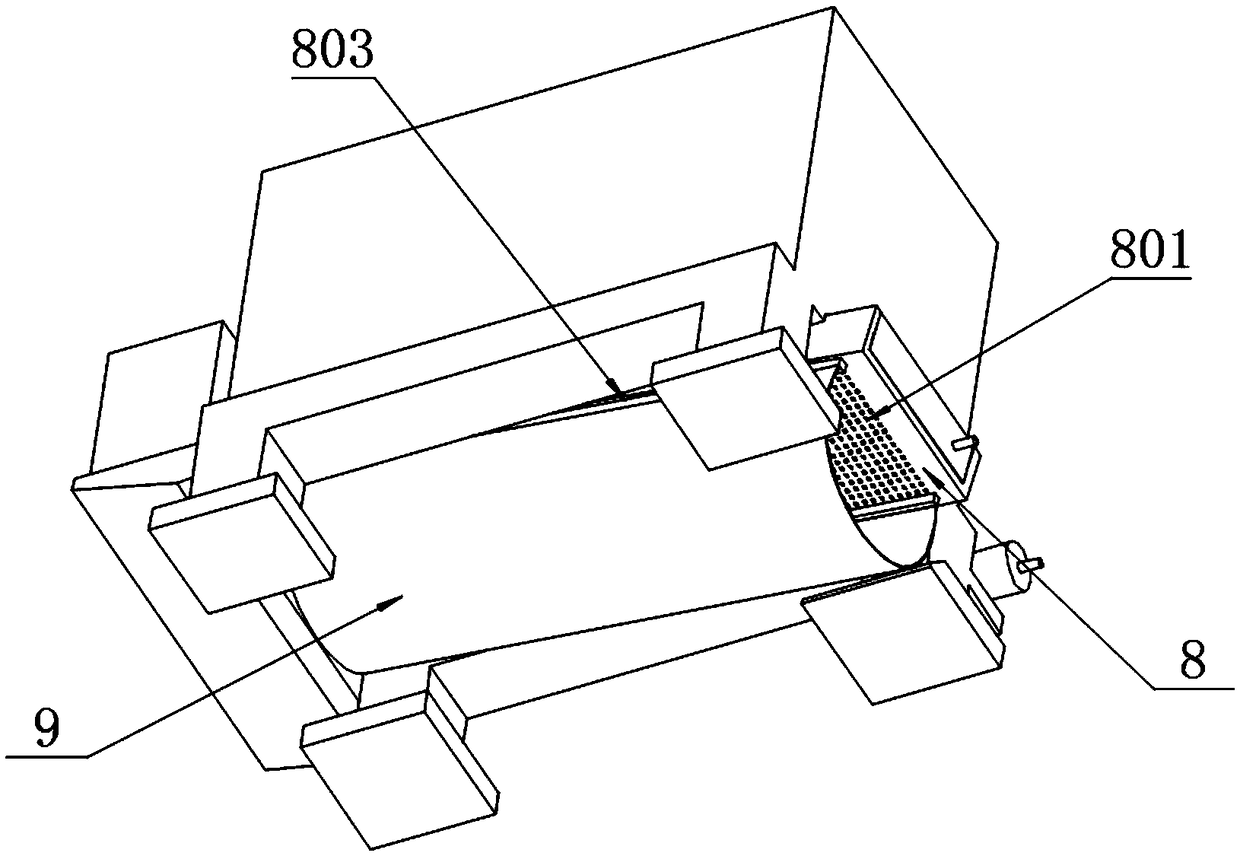

[0031] as attached figure 1 to attach Figure 10 Shown:

[0032] The invention provides a pair of roller crushing equipment for building construction, which has the simple switching of mining stone crushing and construction engineering dual-workplaces, and has an environmentally friendly structure in the process of building lime crushing, including: a bracket 1, a crushing cabin 2. Material inlet 3, counter roller 4, electrical box 5, first motor 6, second motor 7, first lower hopper 8, leakage hole 801, gear seat 802, connecting seat 803, limit slot 804, second Bottom hopper 9, pulley 10, discharge cloth bag 11, stirring shaft 12, gear reversing box 13 and plug-in discharge plate 14: the crushing cabin 2 is a rectangular cabin structure, and it is installed on the bracket by bolts 1, and on the top surface of the crushing chamber 2, there is a rectangular feeding port, and the top of the feeding port is equipped with a feeding port 3 with an inverted trapezoidal structure; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com