Multifunctional stapler

A stapler, multi-functional technology, applied in binding, machining/deformation, etc., can solve problems such as high manual origami, complex cost of electromechanical systems, irregularities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

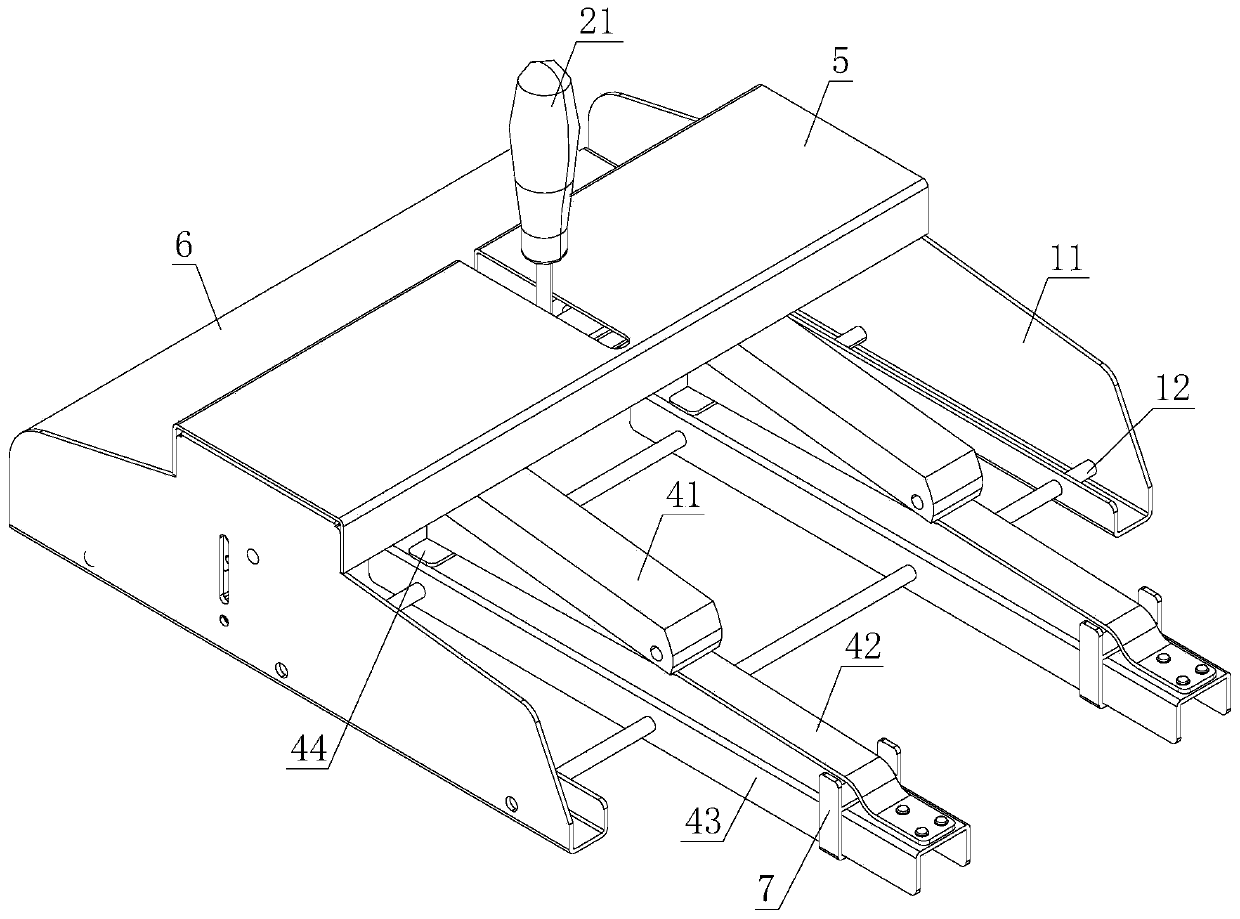

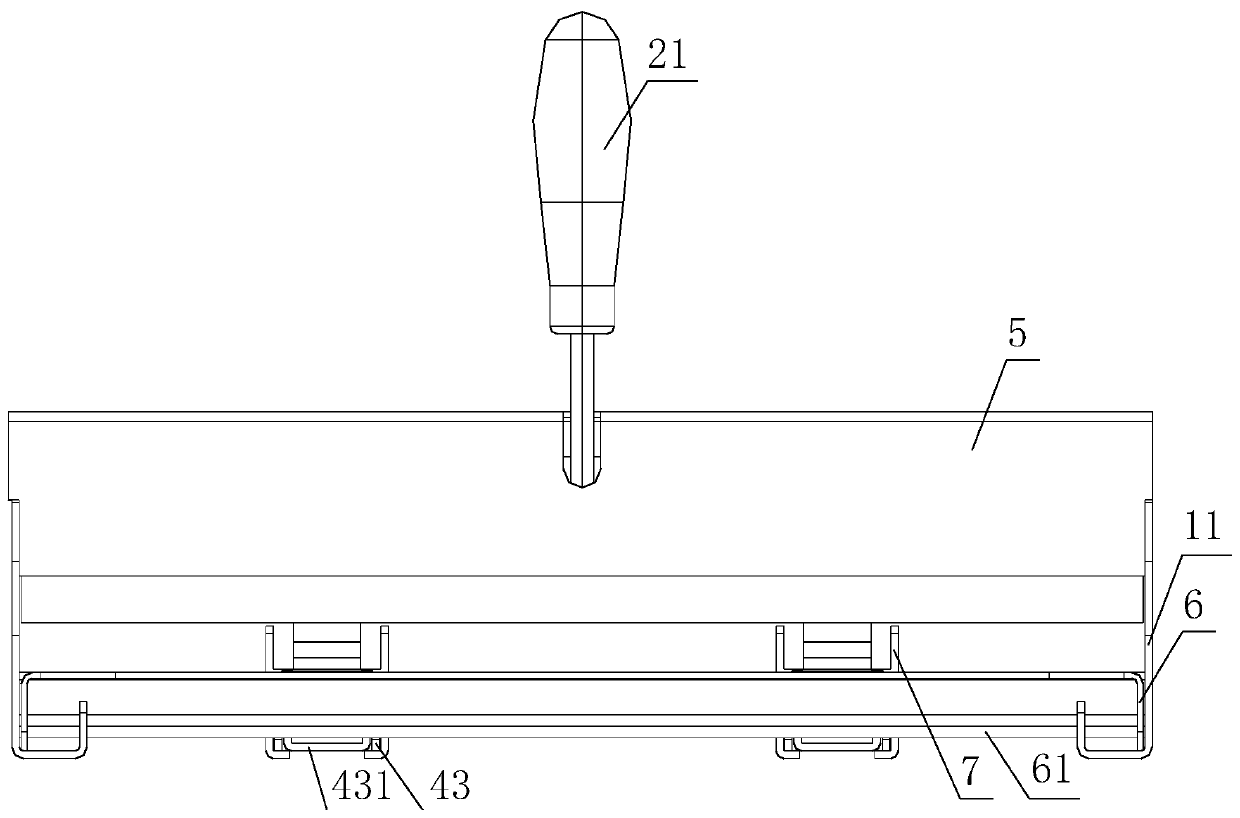

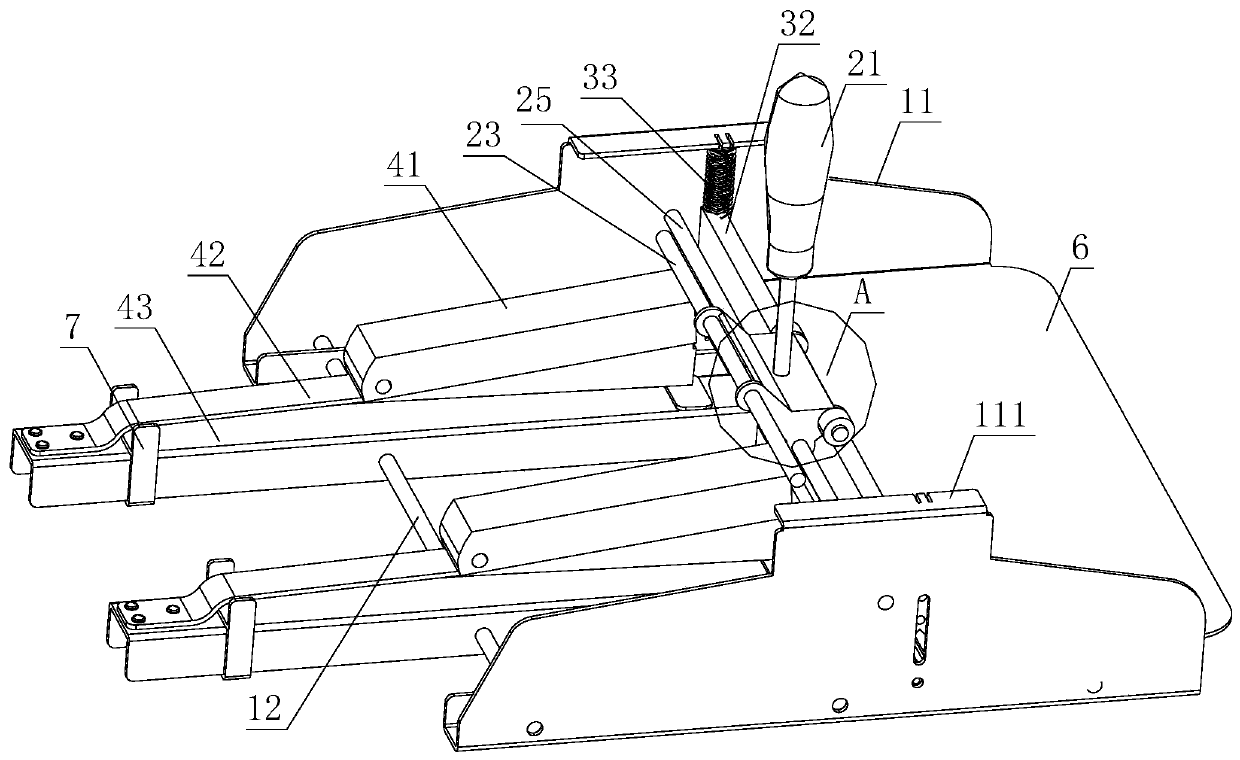

[0030] Such as Figure 1 to Figure 4 As shown, the preferred embodiment of the multifunctional seam stapler of the present invention includes a paper folding mechanism, a binding mechanism, a pressing mechanism, a cover plate 5, a cardboard 6, a spacer 7 and a mounting seat; the paper folding mechanism, the binding mechanism and The pressing mechanisms are all arranged on the installation seat; the paper folding mechanism is used for folding paper to make paper crease; the binding mechanism is used for binding paper. The pressing mechanism is used for pressing the folding mechanism and the binding mechanism. The cover plate 5 is arranged on the mounting seat, and the cover plate 5 is covered on the pressing mechanism, so as to avoid pinching hands, etc. and shielding dust during paper folding or binding. The paper supporting board 6 is installed at the front end of the mounting seat, and the paper supporting board 6 is positioned by a positioning shaft 61; the paper supportin...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 lies in the structure of the pressing mechanism.

[0038] Described pressing mechanism comprises handle 21, origami pressing bar 22, binding pressing bar 23 and rotating shaft 25, and described origami pressing bar 22 is connected with handle 21 by origami connecting piece 241, and described binding pressing bar 23 is connected with handle by binding connecting piece 242. 21, the handle 21 is connected to the rotating shaft 25, and the rotating shaft 25 is arranged on the two side plates 11. In other implementation manners, it is also possible that the folding press bar 22 and the binding press bar 23 are both connected to the rotating shaft 25 . It should be understood that the folding connector 241 and the binding connector 242 may be in the shape of a rod or a sheet, and the folding connector 241 and the binding connector 242 may be integrally formed.

Embodiment 3

[0040] This embodiment differs from Embodiment 1 and Embodiment 2 in that the structure of the pressing mechanism is different.

[0041] Described pressing mechanism comprises handle 21, folding paper pressing bar 22, binding pressing bar 23 and rotating shaft 25, origami pressing bar 22 is connected with rotating shaft 25, binding pressing bar 23 is connected with handle 21, and described handle 21 is connected with rotating shaft 25. In other embodiments, the binding pressing rod 23 may also be connected to the rotating shaft 25 , and the folding pressing rod 22 may be connected to the handle 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com