Coaxiality precision machining guarantee method of long-overhanging combination machining part

A combined processing and precision processing technology, applied in the field of mechanical processing, can solve the problems of increasing the time of inspection and measurement deviation, unstable product quality, unfavorable large-scale processing, etc., to improve processing efficiency, shorten production cycle, and increase processing qualifications. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

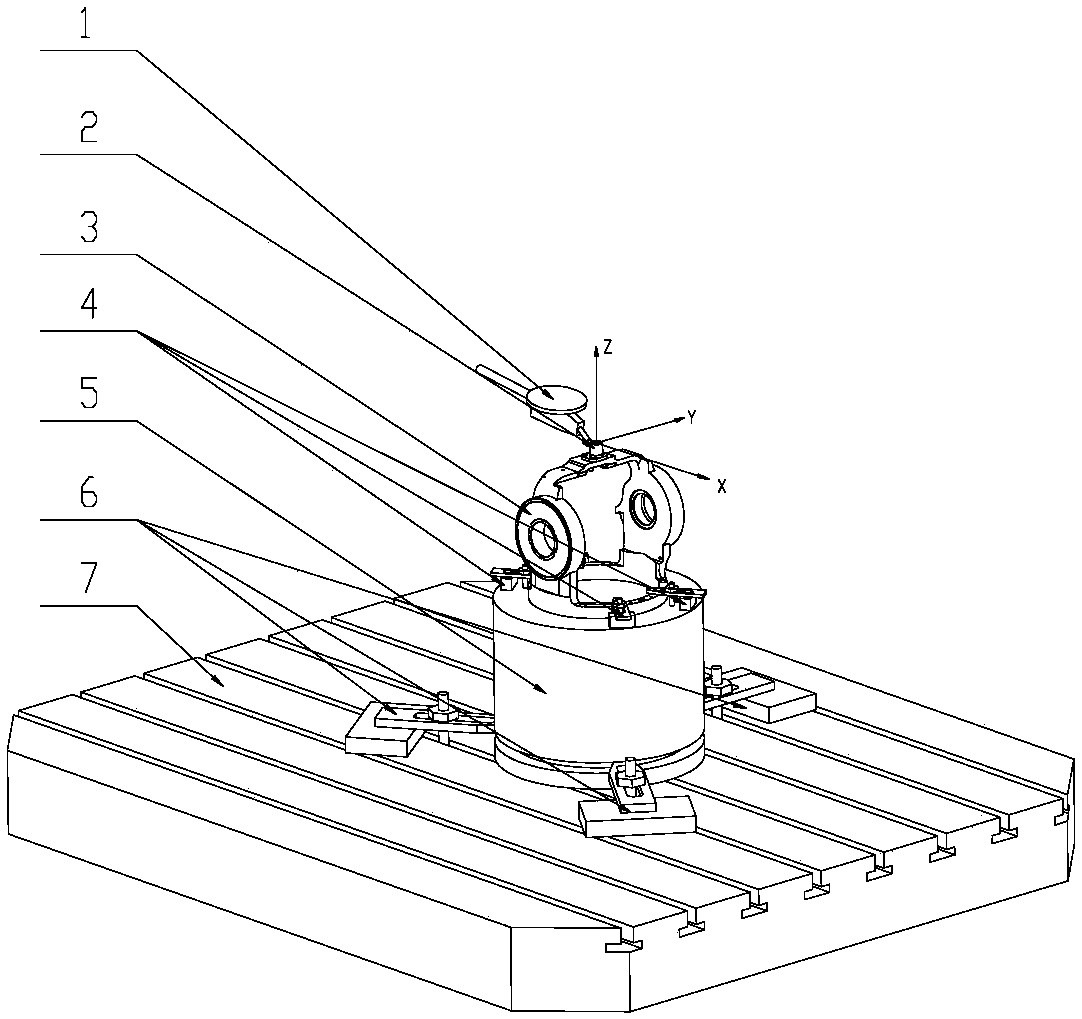

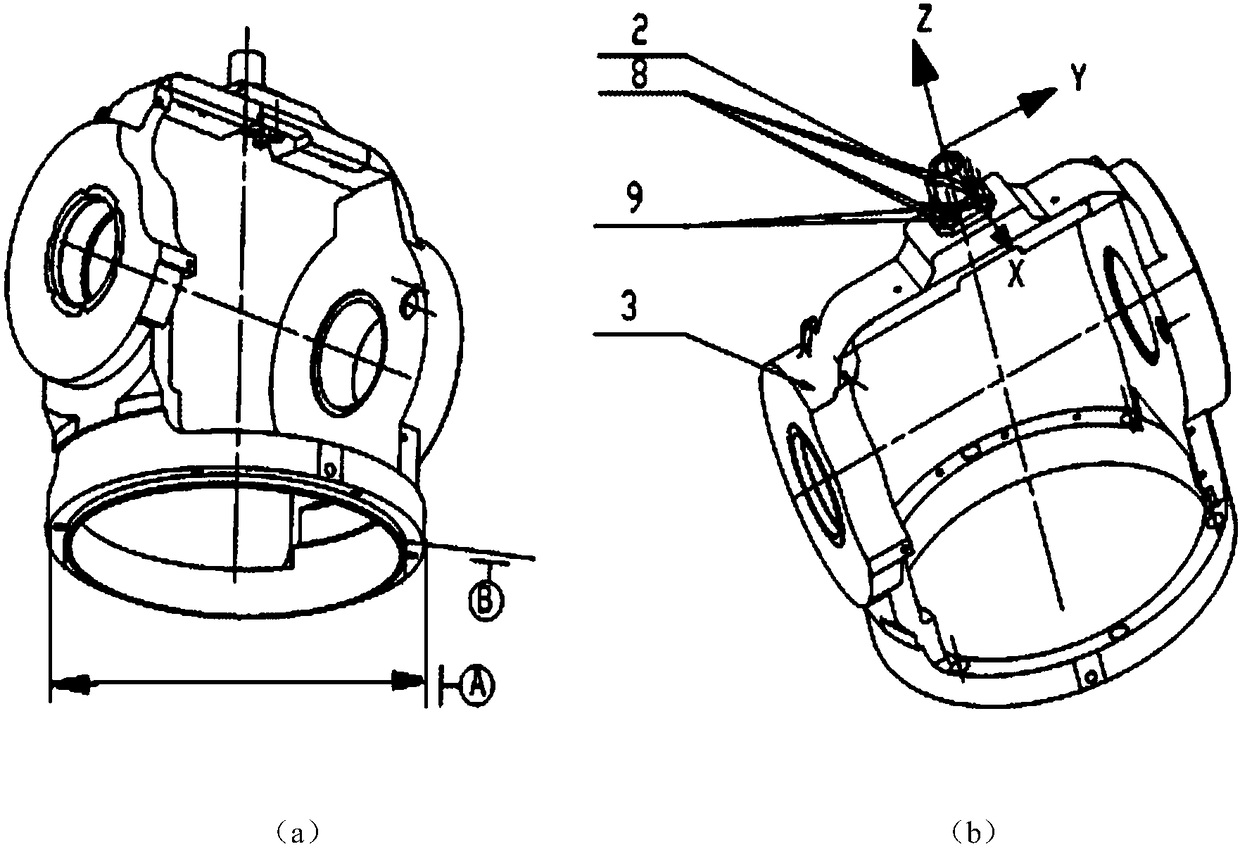

[0027] The present invention will now be further described in conjunction with the embodiments and drawings:

[0028] According to the structural characteristics of long overhang combined processing parts, design and manufacture suitable clamping tooling; by adjusting the position of the small round shaft, the measured values of △1, △2, △3, △4 are approximately equal, and the maximum mutual difference is 0.005mm The method within eliminates various clamping errors, random errors and machine precision errors.

[0029] The invention is directed to the structural characteristics of a long overhang combined processing part, and involves making suitable tooling, finding reasonable processing steps, scientific alignment methods, and correct processing techniques to ensure the requirements of verticality and coaxiality of the parts.

[0030] First, according to the structural characteristics of a long overhang combined processing part, the tooling 5 is designed and manufactured. The desig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap