Positive thick film photoresist for CIS industry

A technology of photoresist and thick film, which is applied in the direction of optics, optomechanical equipment, photoplate making process of pattern surface, etc. It can solve the problems of glue type collapse, inability to maintain a steep angle, peeling of positive photoresist, etc. , to achieve a high level of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

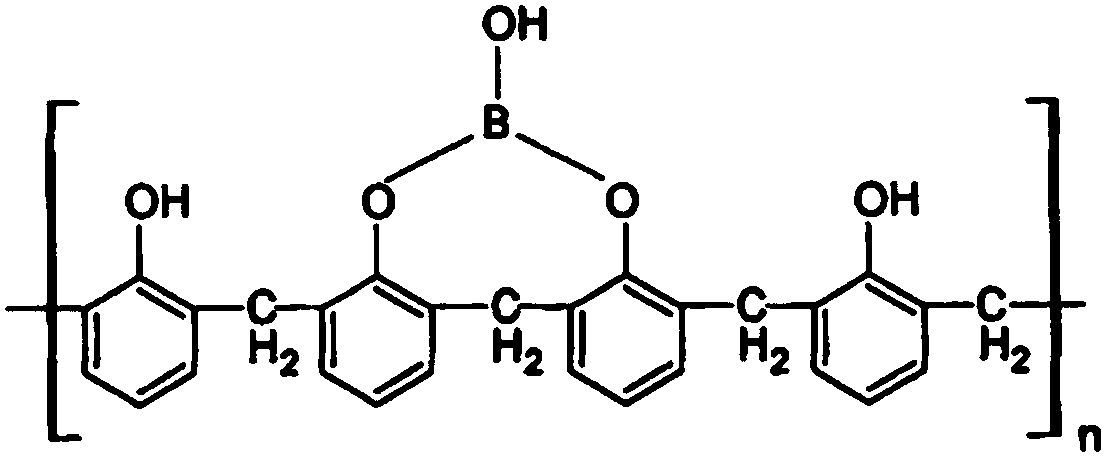

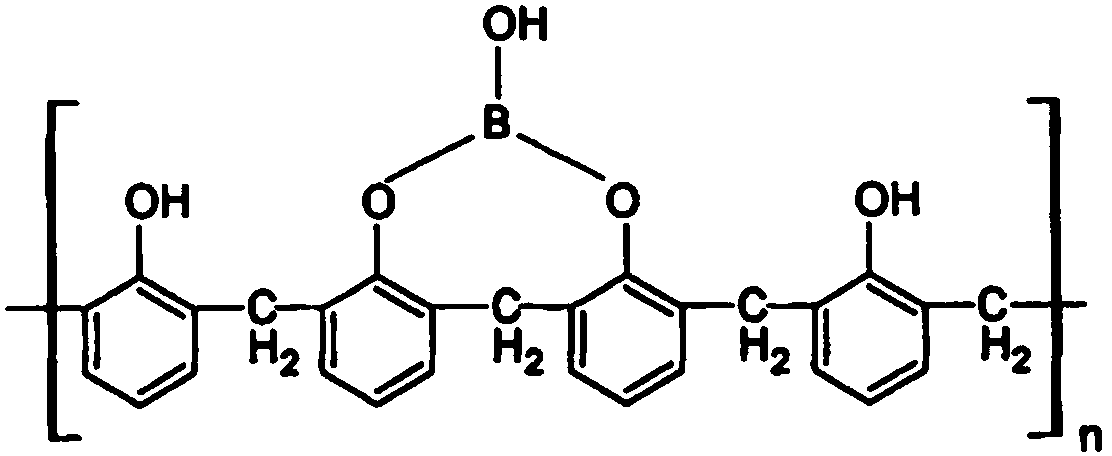

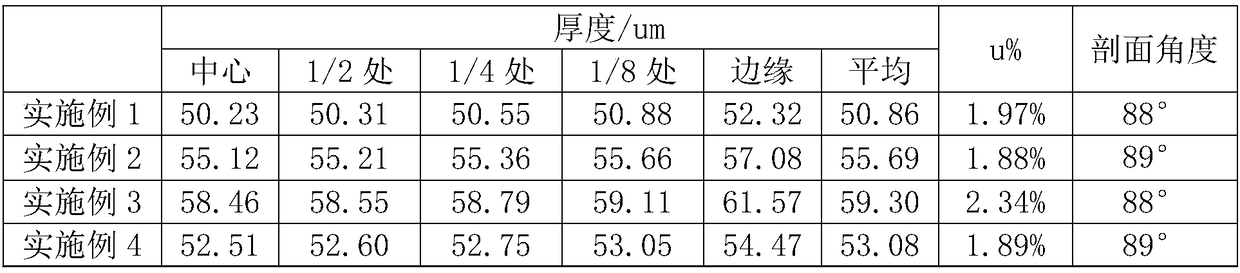

[0017] Mix the raw materials according to the ratio shown in Table 1, wherein the modified phenolic resin is a phenolic resin with the following structure with a molecular weight between 8000 and 15000, which will affect the coating and exposure performance.

[0018]

[0019] The photosensitizer is 2.3.4-trihydroxybenzophenone-1,2-naphthoquinonediazo-5-sulfonate, which affects the deviation of exposure energy.

[0020] The leveling agent is a perfluoroalkyl polyether surfactant, which affects the uniformity of coating.

[0021] The loosening agent is 2,3,4-trihydroxybenzophenone, which affects the gas permeability of the photoresist.

[0022] The solvent is ethyl lactate, which affects the deviation of the viscosity and affects the coating film thickness and exposure energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com