Loudspeaker module

A loudspeaker module and loudspeaker technology, which is applied in the direction of sensors, loudspeakers, electrical components, etc., can solve the problem of falling off of the separated sound hole, the combination strength of the separated sound hole and the module shell is not enough to overcome the bending moment, and the failure of the reliability test, etc. problem, to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

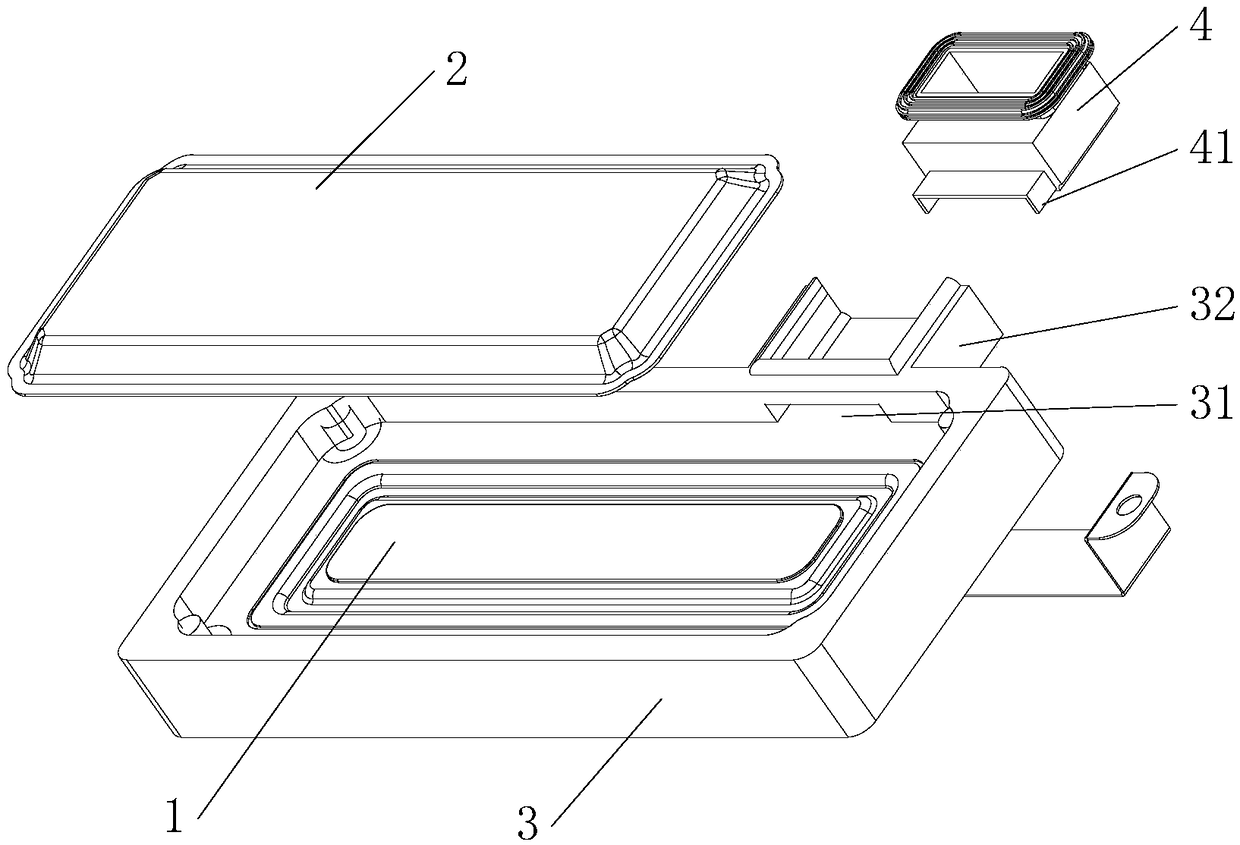

[0020] Such as figure 1 As shown, the present invention provides a speaker module, the module includes a module housing and a speaker unit, an accommodation space is formed in the module housing, the speaker unit is accommodated in the accommodation space, and the accommodation The space is divided into front and rear acoustic chambers. The speaker unit is a moving coil unit or a moving iron unit. For ease of description, a moving coil unit is taken as an example in this embodiment. The moving coil monomer includes a vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com