Method for toughening polypropylene by organic and inorganic hybrid core-shell nanoparticles

A nanoparticle, polypropylene technology, applied in the field of polymer material modification, can solve the problems of poor compatibility, material rigidity and tensile strength decrease, loss of rigidity and other problems, achieve good rigidity and toughness, wide application value, excellent increase The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

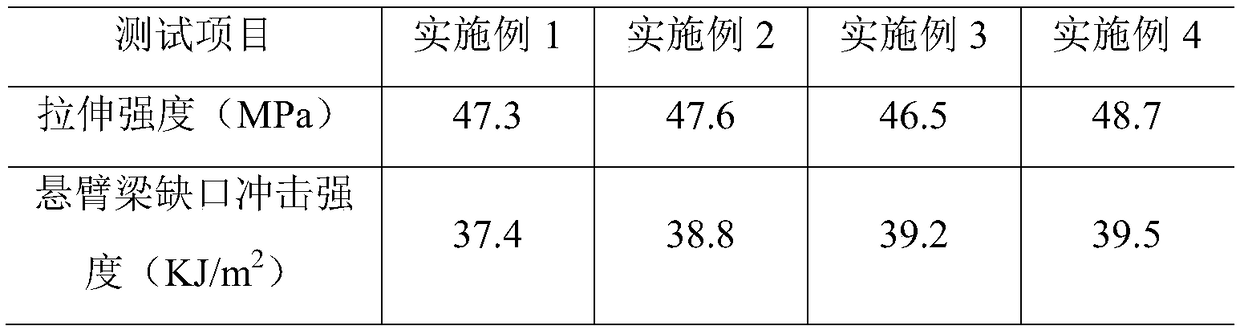

Examples

Embodiment 1

[0020] The present invention designs a novel core-shell nano-particle toughened polypropylene composite material, which includes the following components and weight percentages: 80-90 parts of polypropylene resin, 10-15 parts of core-shell nano-particles, and 1 part of antioxidant ~3 parts and 1~3 parts of dispersant are obtained by blending.

[0021] A method for preparing novel core-shell nanoparticles, comprising the following steps:

[0022] a. Preparation of surface-modified silica: Add silica nanoparticles into an organic solvent, add 2-bromoisobutyryl bromide drop by drop under an ice-water bath, and react for 6 hours after naturally rising to room temperature. In the above preparation process of surface-modified silica, the organic solvent is anhydrous dichloromethane.

[0023] b. Preparation of core-shell nanoparticles: Add the surface-modified inorganic nanoparticles obtained in step a into a polymerization bottle and dissolve them with anisole, then add CuBr, PMDET...

Embodiment 2

[0028] The present invention designs a core-shell nano-particle toughened polypropylene composite material, which includes the following components and weight percentages: 80-90 parts of polypropylene resin, 10-15 parts of core-shell nano-particles, 1-15 parts of antioxidant 3 parts and 1-3 parts of dispersant are obtained by blending.

[0029] A method for preparing novel core-shell nanoparticles, comprising the following steps:

[0030] a. Preparation of surface-modified silica: Add silica nanoparticles into an organic solvent, add 2-bromoisobutyryl bromide drop by drop under an ice-water bath, and react for 6 hours after naturally rising to room temperature. In the above preparation process of surface-modified silica, the organic solvent is anhydrous dichloromethane.

[0031] b. Preparation of core-shell nanoparticles: Add the surface-modified inorganic nanoparticles obtained in step a into a polymerization bottle and dissolve them with anisole, then add CuBr, PMDETA and m...

Embodiment 3

[0036] The present invention designs a core-shell nano-particle toughened polypropylene composite material, which includes the following components and weight percentages: 80-90 parts of polypropylene resin, 10-15 parts of core-shell nano-particles, 1-15 parts of antioxidant 3 parts and 1-3 parts of dispersant are obtained by blending.

[0037] A method for preparing novel core-shell nanoparticles, comprising the following steps:

[0038] a. Preparation of surface-modified silica: Add silica nanoparticles into an organic solvent, add 2-bromoisobutyryl bromide drop by drop under an ice-water bath, and react for 6 hours after naturally rising to room temperature. In the above preparation process of surface-modified silica, the organic solvent is anhydrous dichloromethane.

[0039] b. Preparation of core-shell nanoparticles: Add the surface-modified inorganic nanoparticles obtained in step a into a polymerization bottle and dissolve them with anisole, then add CuBr, PMDETA and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com