A flap retractable control mechanism for rotating wings

A technology of rotating wings and operating mechanisms, applied in the direction of wing adjustment, wing lift efficiency, aircraft parts, etc., can solve the problems that front and rear symmetrical airfoil flaps cannot be applied, and achieve the effect of reducing flow separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

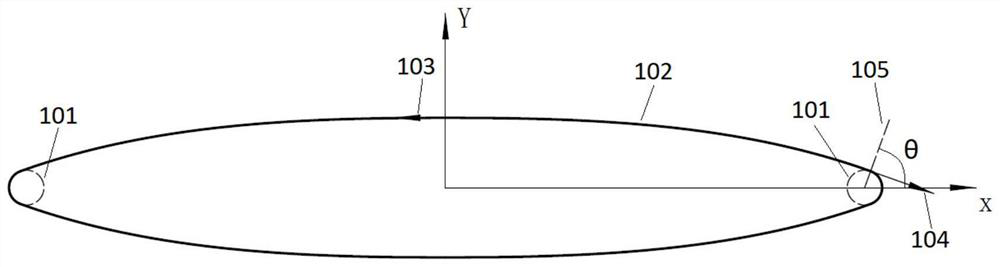

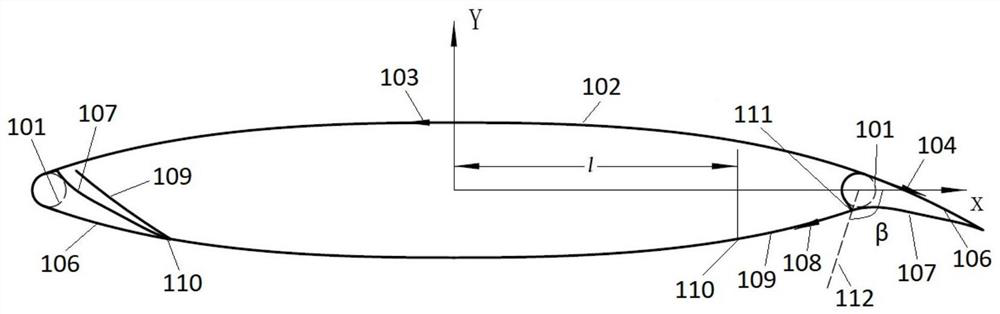

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

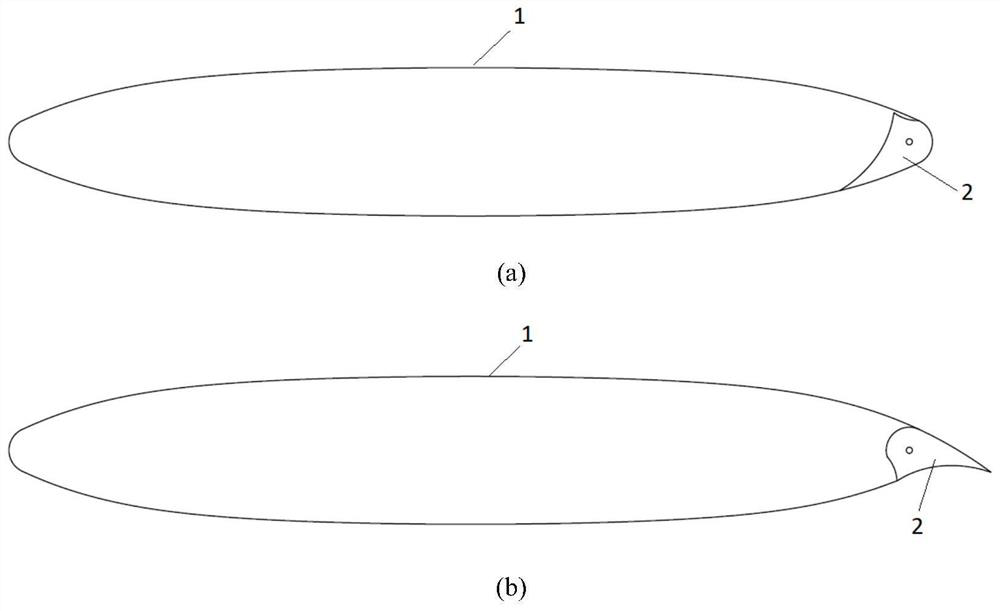

[0027] In this embodiment, flaps are provided at the front and rear ends of the airfoil. In actual use, the flaps on the windward side are folded, and the flaps on the other side are opened. The reason why flaps are set at both ends is that during the rotation, the windward end and the leeward end of the rotating wing on both sides of the rotating shaft are the same, but when the rotating wing stops turning to form a fixed wing, for one side of the rotating shaft When the rotating wing rotates at high speed, the windward end will become the leeward end. At this time, the flap of this end needs to be opened in the fixed-wing flight mode, and the other end changes from the leeward end to the windward side. Flaps retracted. After the flaps are retracted, the sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com