A kind of defrosting method and freezing equipment

A technology for freezing equipment and freezing chambers, which is applied to lighting and heating equipment, refrigerators, refrigeration components, etc., can solve the problems of increasing the opening time of the defrosting heater, excessive frosting of the freezing equipment, and affecting the cooling effect of the equipment. The effect of reducing the defrosting interval, stable cooling effect, and prolonging the service life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

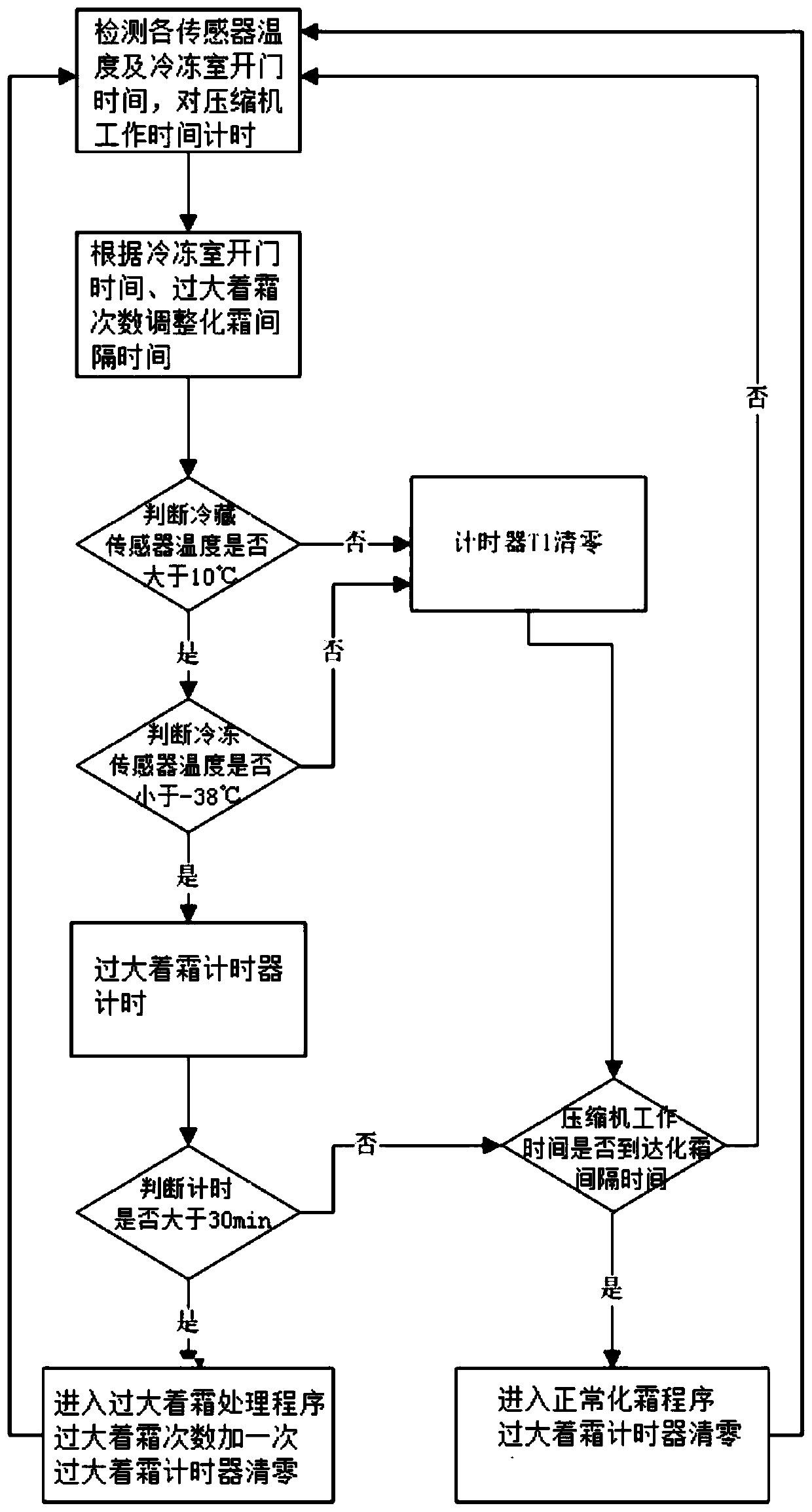

[0052] This embodiment relates to a refrigerator. The defrosting process of the refrigerator is as follows: figure 1 shown, including:

[0053] (1) Detect the temperature of each sensor and the door opening of the freezer: power on to detect the temperature of the refrigerating sensor, the temperature of the freezing sensor, the temperature of the freezing and defrosting sensor, and detect the opening time of the freezer. If there is a fault in the sensor, it will run according to the special fault program to remind the user to repair the sensor; if there is no fault in the sensor, the compressor will run according to whether there is cooling demand in the compartment.

[0054] (2) Adjust the defrosting interval according to the opening time of the freezer and the number of times of excessive frosting: After testing, the number of times of excessive frosting is 1, and the opening time of the freezer is 30s. Among them, the initial frost interval time is 1440min, and the adjus...

Embodiment 2

[0059] Present embodiment continues on the basis of embodiment 1, as figure 1 As shown, the process is:

[0060] (1) Detect the temperature of each sensor and the door opening of the freezer: power on to detect the temperature of the refrigerating sensor, the temperature of the freezing sensor, the temperature of the freezing and defrosting sensor, and detect the opening time of the freezer. If there is a fault in the sensor, it will run according to the special fault program to remind the user to repair the sensor; if there is no fault in the sensor, the compressor will run according to whether there is cooling demand in the compartment.

[0061] (2) Adjust the defrosting interval according to the opening time of the freezer and the number of times of excessive frosting: After testing, the number of times of excessive frosting is 2, and the opening time of the freezer is 500s. Among them, the initial frost interval time is 1440min, and the adjustment time for excessive frost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com