Electrical connector

An electrical connection and channel technology, applied in the direction of connection, circuit, connection device components, etc., can solve the problems of many assembly steps, difficult automatic production and automatic assembly, etc., to reduce the total number, reduce the complexity and assembly time, The effect of improving process and simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

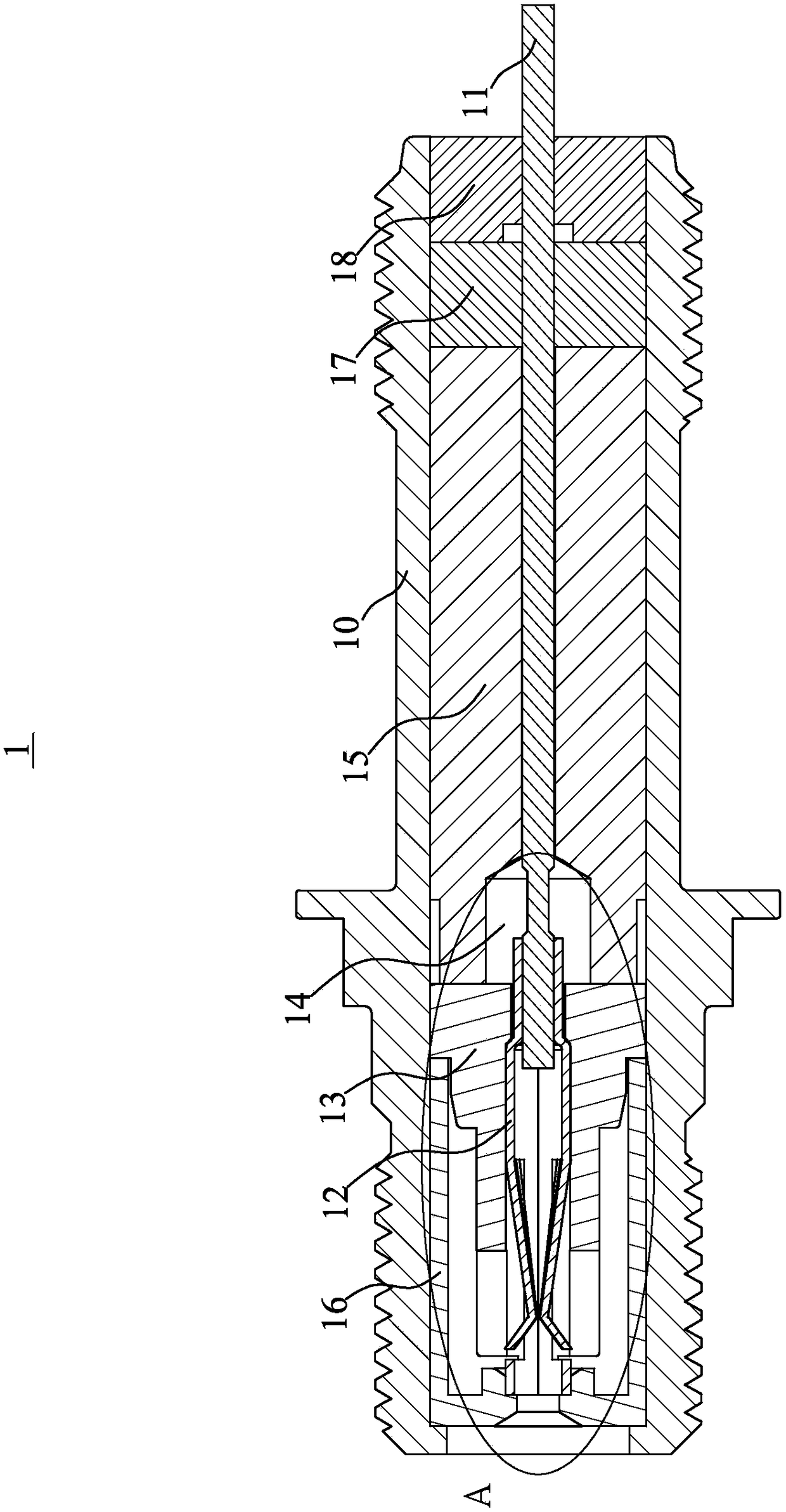

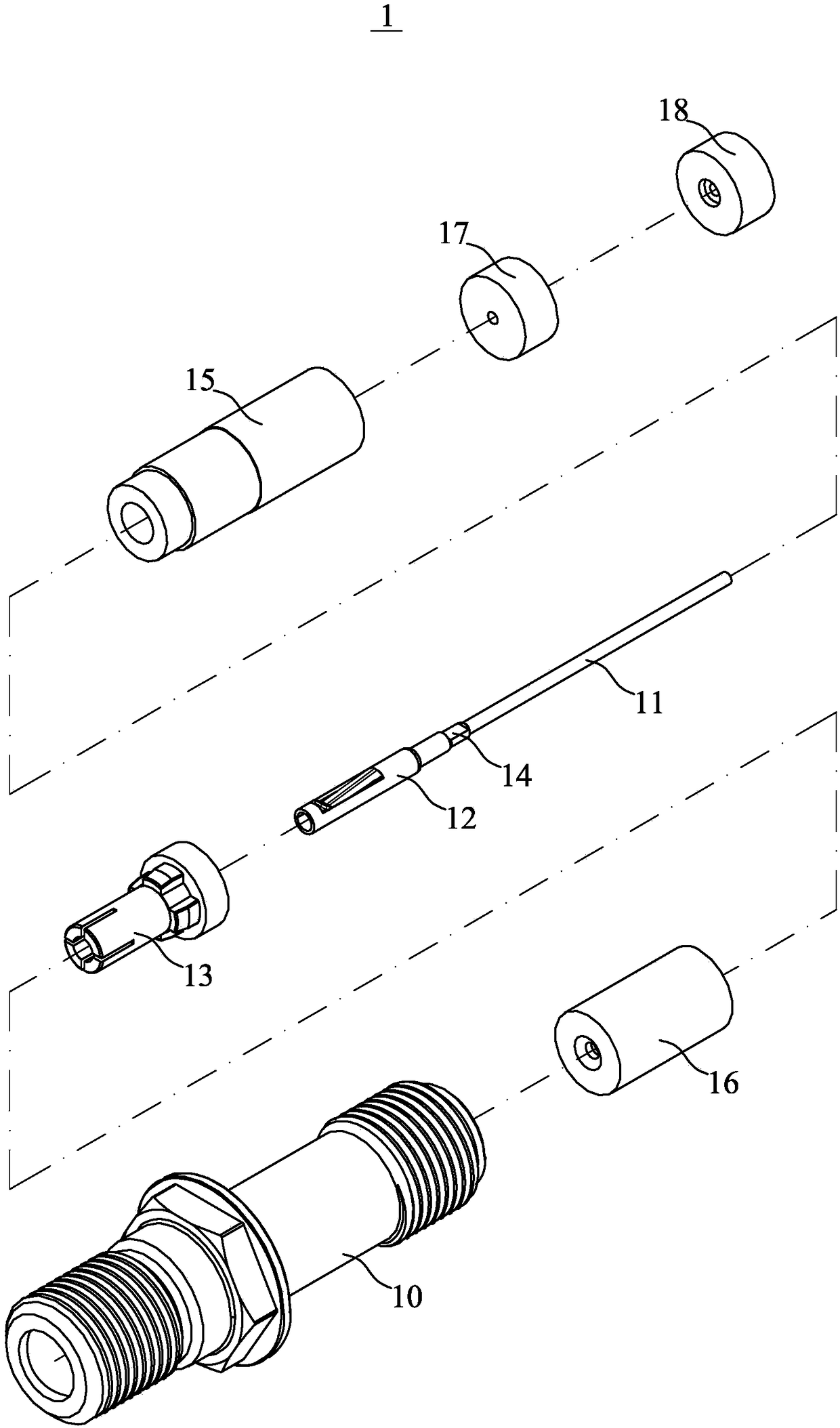

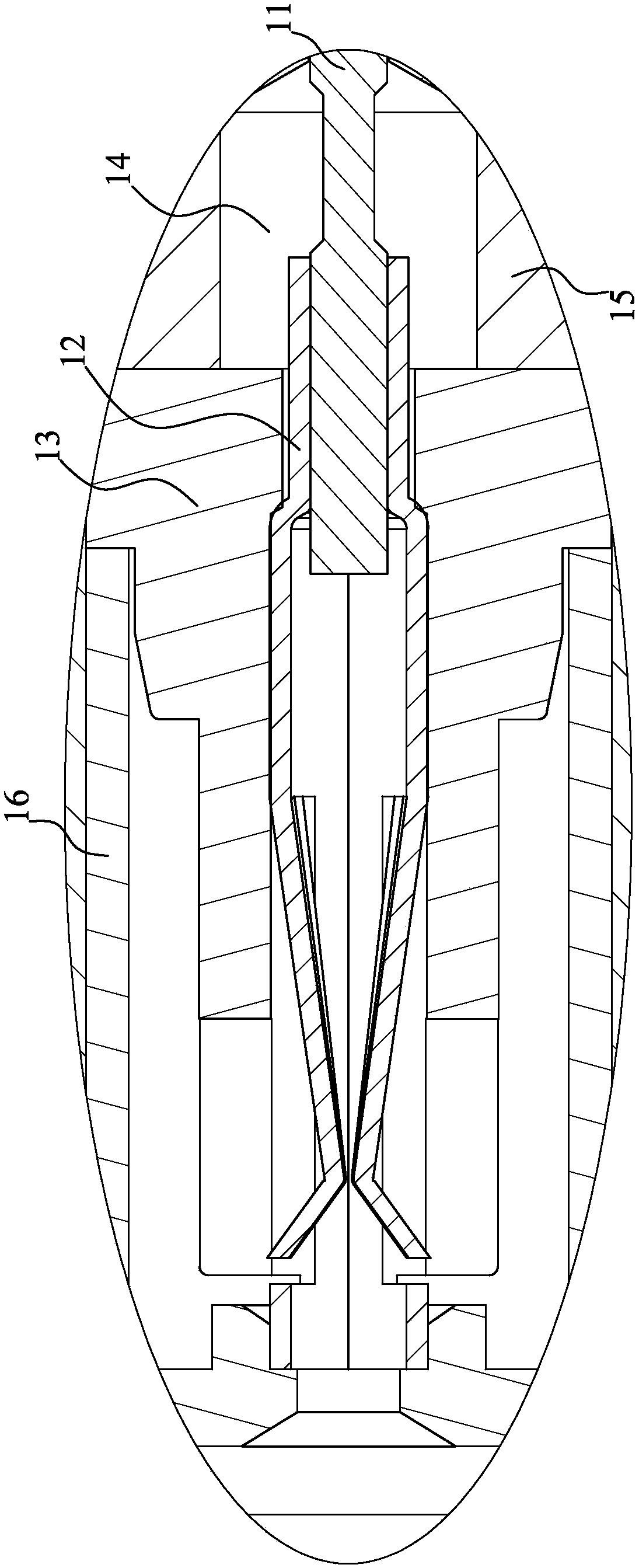

[0026] In order to further have a clearer and more detailed understanding and understanding of the structure, use and features of the present invention, a preferred embodiment is given, and the details are as follows in conjunction with the drawings:

[0027] Please refer to Figure 4 to Figure 7 As shown, the electrical connector 2 of the present invention mainly includes six major structures including a housing 3 , an inner cover 4 , a pad 5 , a wire 6 , a shrapnel 7 and a stopper 8 .

[0028] The shell 3 is mainly made of insulating plastic material, which provides a protective effect on parts such as internal wires and the parts that the human body has the opportunity to touch. The inside of the shell 3 is formed with an accommodating channel 30, and the accommodating channel Two opposite ends of the 30 respectively form a mounting hole 31 and a locking hole 32 .

[0029] The accommodating passage 30 forms a first aperture 301 , a second aperture 302 and a third aperture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com