Hydrocarbon fuel-rich propellant and preparation method thereof

A technology of hydrocarbon fuel and propellant, which is applied to attack equipment, generation of compressed gas, ammonium perchlorate composition, etc., can solve problems such as restricting application, and achieve the effects of improving storage performance, wide source, and high gas yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0044] The invention also discloses a preparation method of hydrocarbon fuel-rich propellant, which comprises the following steps:

[0045] (1) Weighing: Precisely weigh each component in a dry environment for use;

[0046] (2) Mixing: Add functional additives to the adhesive and mix by hand to obtain a pre-mixed slurry, then add the metal fuel, hydrocarbon fuel, and oxidizer to the vertical mixer to mix uniformly, and then add the curing agent to continue Mix, control the mixing temperature to 30℃~50℃, the mixing time is 70min~110min, wait until the system is completely mixed and uniformly discharged;

[0047] (3) Pouring and curing: the slurry is vacuum poured and cured in a dry environment at 50°C to 70°C for 5 to 8 days to obtain a propellant product.

[0048] According to the characteristics of hydrocarbon fuel solid propellant, adjusting the relative performance of hydrocarbon fuel-rich propellant can make it widely used in a variety of advanced air-breathing power plants, such ...

Example Embodiment

[0049] Example 1

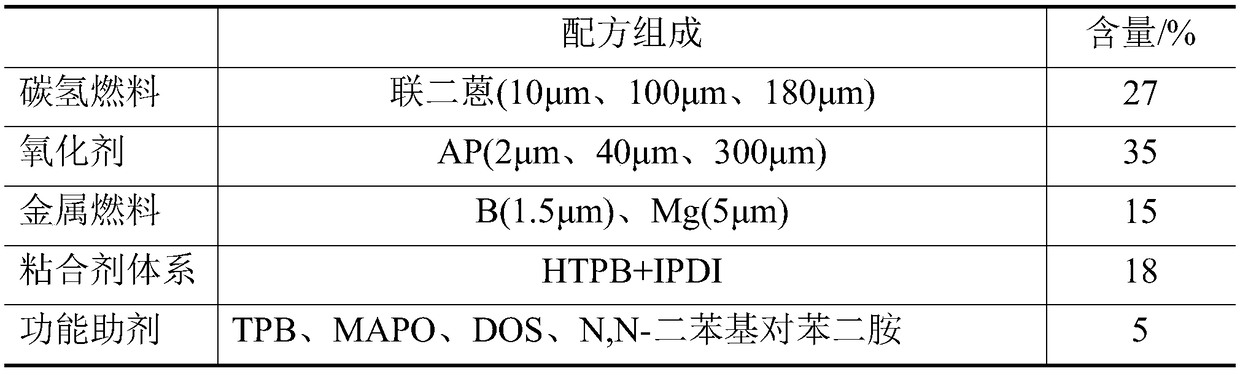

[0050] (1) Propellant formula

[0051]

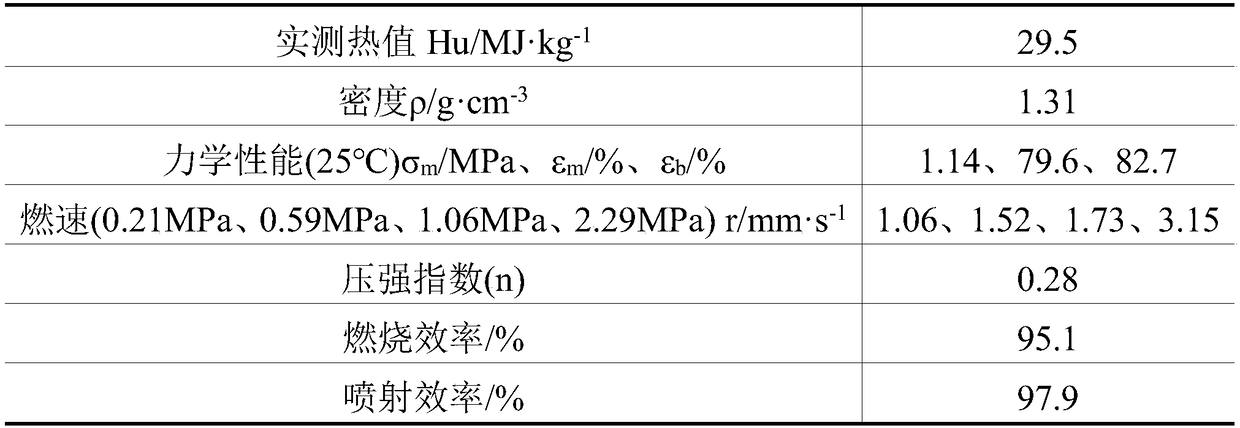

[0052] (2) Propellant performance

[0053]

[0054] It can be known from Example 1 that the measured calorific value = 29.5MJ·L -1 , Combustion efficiency = 95.1%, excellent combustion performance.

Example Embodiment

[0055] Example 2

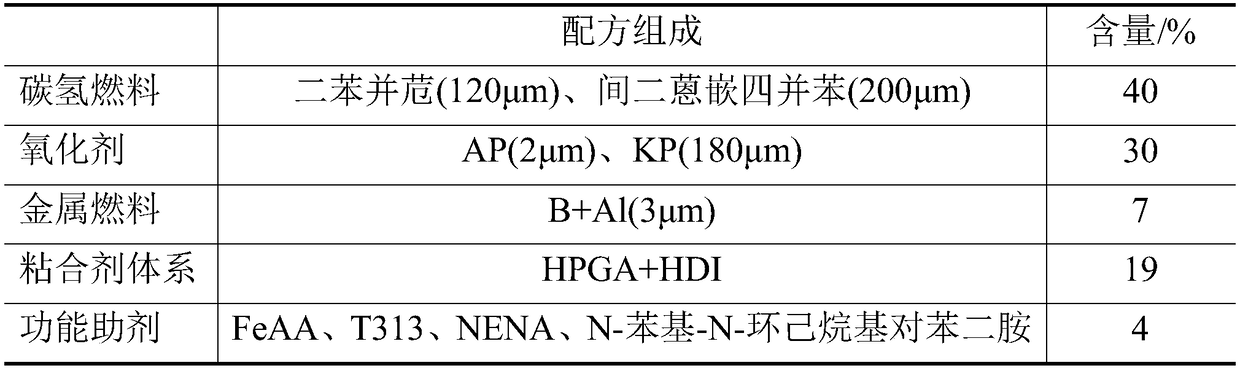

[0056] (1) Propellant formula

[0057]

[0058] (2) Propellant performance

[0059]

[0060] It can be known from Example 2 that the measured calorific value = 31.9MJ·L -1 , Combustion efficiency = 96.0%, excellent combustion performance.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap