Forming method of electric cable and insulating part thereof

A technology of insulating parts and molding methods, which is applied in the direction of insulating conductors/cables, electrical components, cables/conductors, etc., can solve the problem of vertical holes that cannot be produced in insulating parts, and achieves the reduction of signal transmission attenuation and dielectric constant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

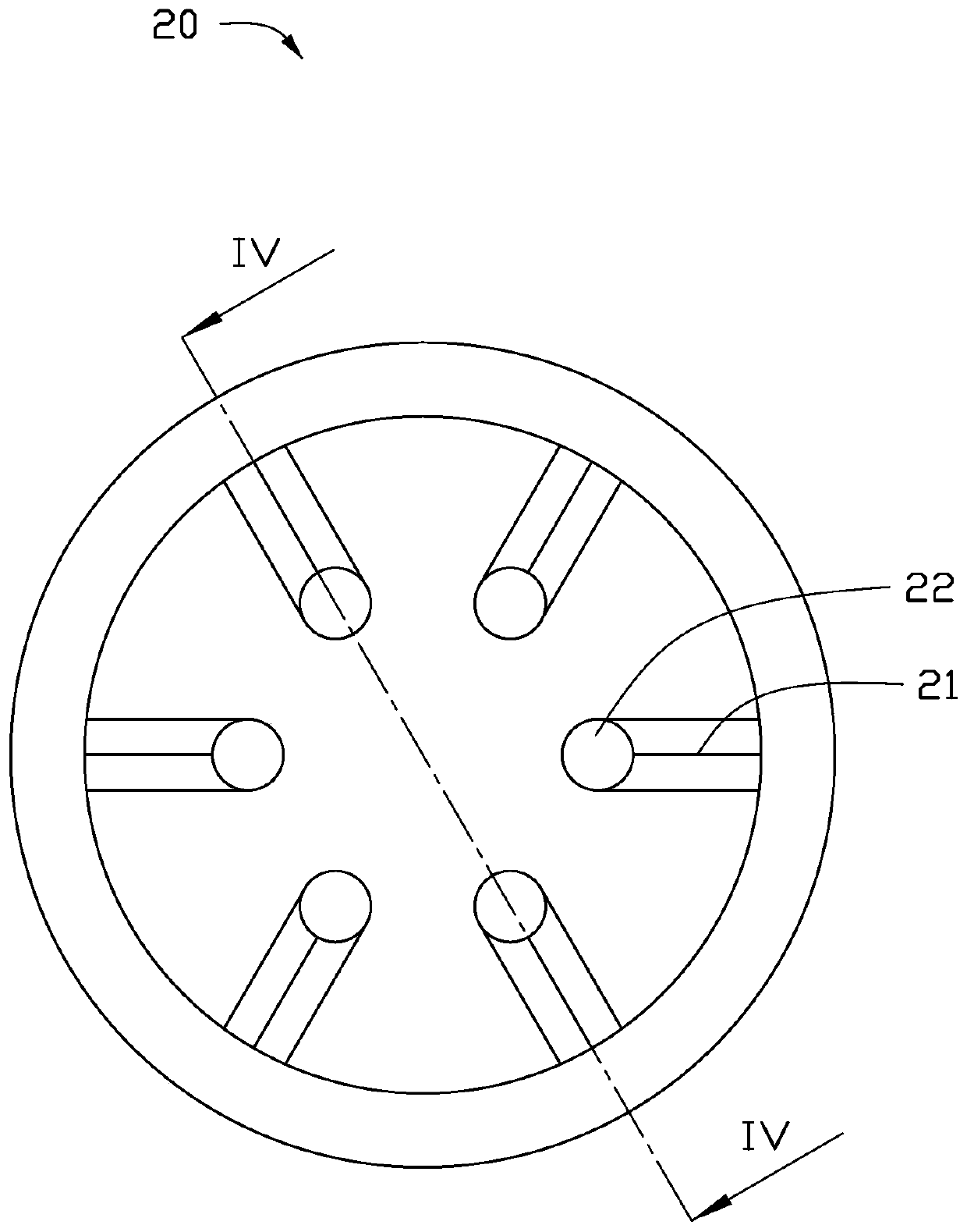

[0028] The technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by a person of ordinary skill in the art without creative work shall fall within the protection scope of the present invention. It should be noted that in this article, "curing" specifically refers to sealing and standing the mixture of PTFE and booster at room temperature. The purpose is to make the booster and PTFE powder fully fuse, which is conducive to subsequent promotion. Extrusion processing is carried out. "Pressing" specifically refers to pouring the matured mixture into a press cylinder, and setting a certain pressure to gradually press the mixture into shape, with the purpose of removing the air mixed in when the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com