Manufacturing method of Fresnel lens, used injection molding mold device and produced Fresnel lens

A Fresnel lens and manufacturing method technology, applied in the direction of lenses, household appliances, other household appliances, etc., can solve the problems of insufficient local filling of the mold cavity and insufficient sharpness of the sawtooth portion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described below in conjunction with specific embodiments, and the advantages and characteristics of the present invention will become clearer along with the description. However, these embodiments are only exemplary and do not constitute any limitation to the scope of the present invention. Those skilled in the art should understand that the details and forms of the technical solutions of the present invention can be modified or replaced without departing from the spirit and scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

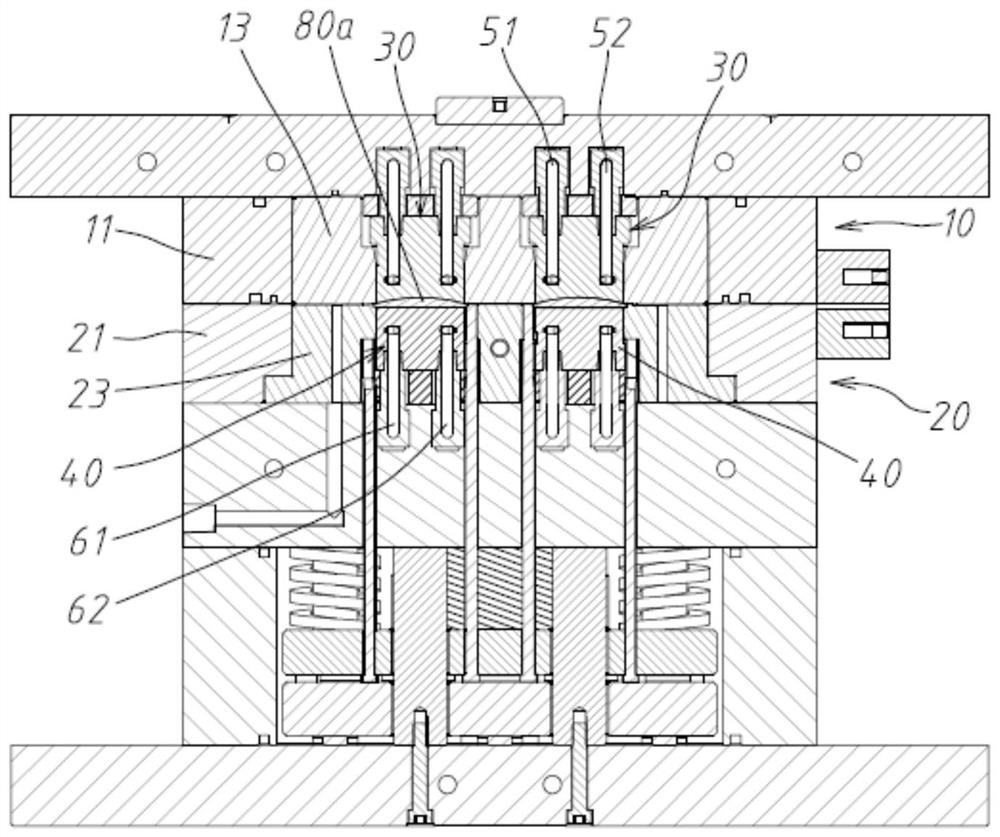

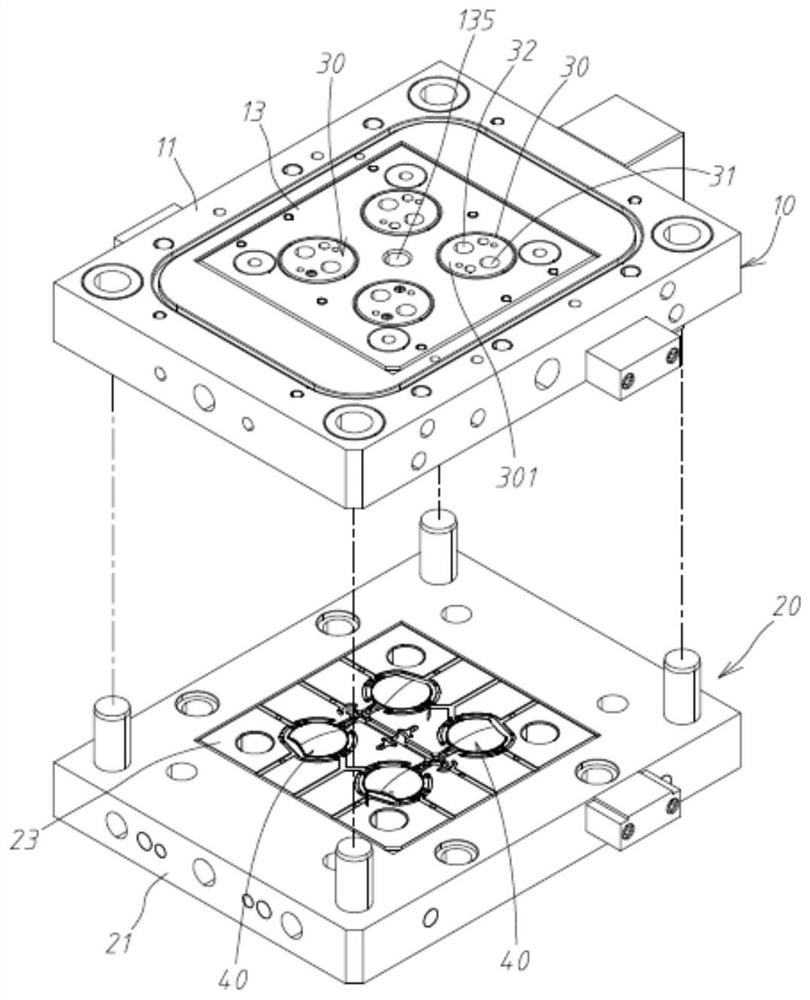

[0088] Please refer to Figure 1 to Figure 3 as well as Figure 16 The Fresnel lens injection molding mold device 1 of the present invention can be connected with a rapid cooling and rapid heating mold temperature control machine 2 and a plastic injection molding machine 3, and includes: a female mold 10, a male mold 20, at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com