Cement clinker

A technology of cement clinker and parts by weight, which is applied in the field of cement clinker, which can solve the problems of high price and increased production costs of enterprises, and achieve the effects of improving overall performance, reducing production costs, and improving slurry fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

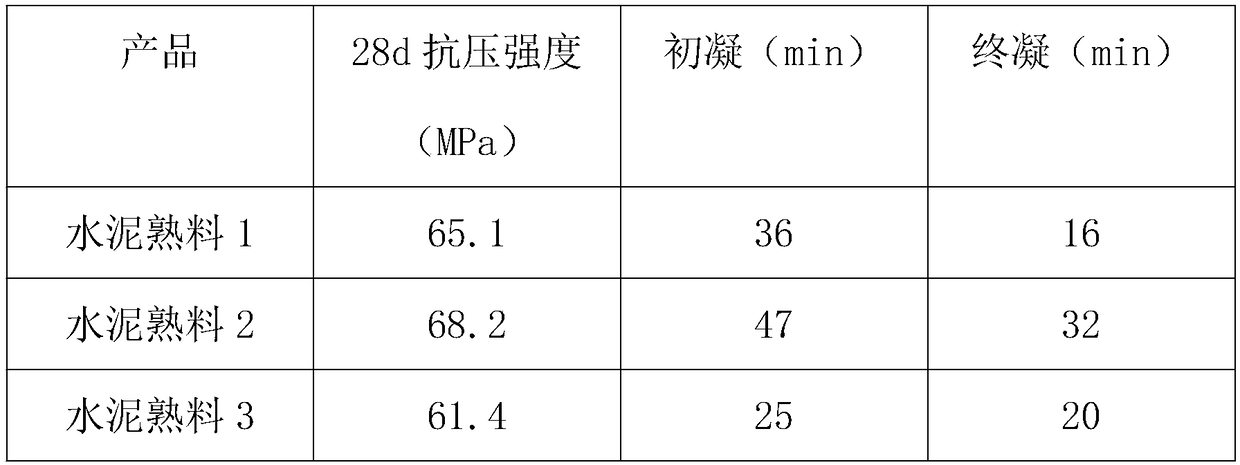

Embodiment 1

[0018] A cement clinker, the cement clinker is composed of the following components in parts by weight: 95-110 parts of limestone, 5-8 parts of phosphorus slag, 3-5 parts of copper slag, 1-3 parts of fly ash, stable Dose 0.1-0.3 part.

[0019] Further, the phosphorus slag is the white granular silicate waste slag obtained by the factory using the electrothermal sublimation method to prepare Huanglin, and its vitreous content is 90%, and the potential mineral composition is mainly pseudolimestone (α-CS), lanceolite (C 3 S 2 ·CaF 2 ) and a small amount of apatite.

[0020] Further, the copper slag is the black granular waste slag discharged from the smelting plant, and its main potential mineral is fayalite (FeO SiO 2 ) and mullite (A 3 S 2 ), wherein the vitreous content is 80%.

[0021] Further, the fly ash comes from a power plant, which contains 80% glass and a small amount of α-quartz (α-SiO 2 ), the potential mineral is mullite (A 3 S 2 ).

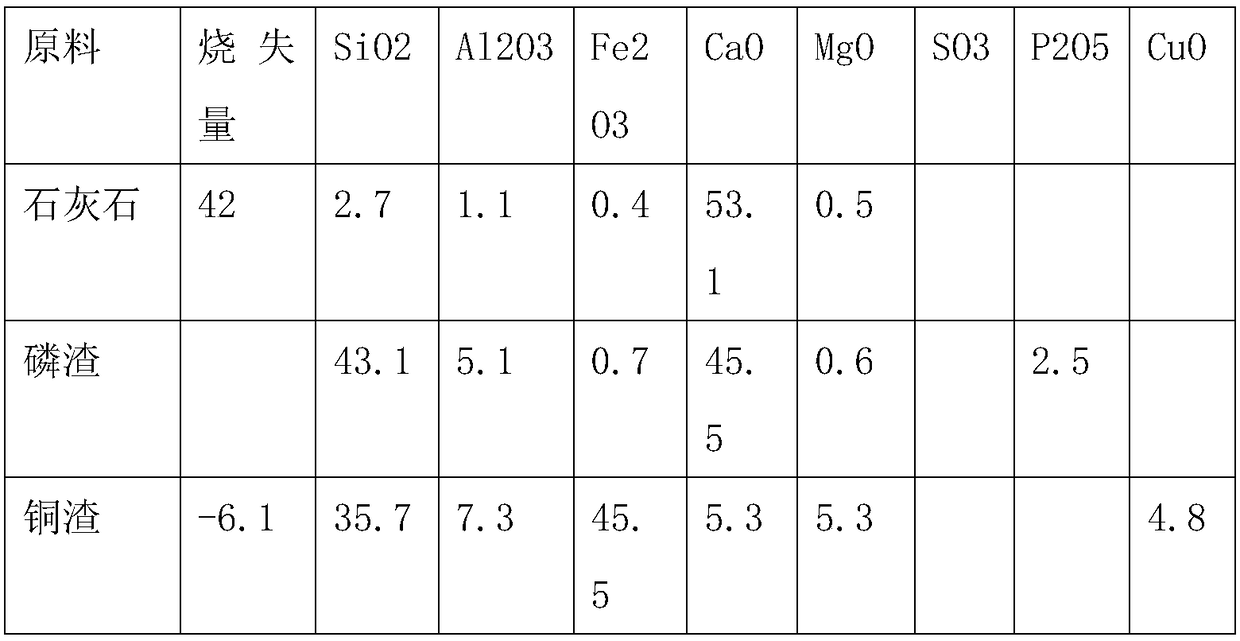

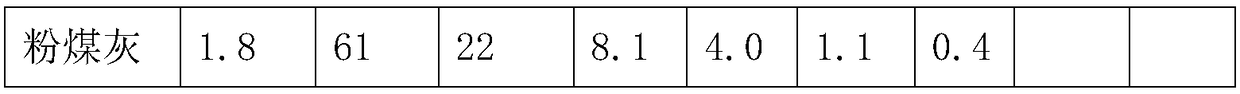

[0022] The main chem...

Embodiment 2

[0029] A cement clinker, the cement clinker is composed of the following components in parts by weight: 95 parts of limestone, 5 parts of phosphorus slag, 3 parts of copper slag, 1 part of fly ash and 0.1 part of stabilizer.

[0030] Further, the phosphorus slag is the white granular silicate waste slag obtained by the factory using the electrothermal sublimation method to prepare Huanglin, and its vitreous content is 90%, and the potential mineral composition is mainly pseudolimestone (α-CS), lanceolite (C 3 S 2 ·CaF 2 ) and a small amount of apatite.

[0031] Further, the copper slag is the black granular waste slag discharged from the smelting plant, and its main potential mineral is fayalite (FeO SiO 2 ) and mullite (A 3 S 2 ), wherein the vitreous content is 80%.

[0032] Further, the fly ash comes from a power plant, which contains 80% glass and a small amount of α-quartz (α-SiO 2 ), the potential mineral is mullite (A 3 S 2 ).

Embodiment 3

[0034] The cement clinker is composed of the following components in parts by weight: 100 parts of limestone, 6 parts of phosphorus slag, 4 parts of copper slag, 2 parts of fly ash and 0.2 part of stabilizer.

[0035] Further, the phosphorus slag is the white granular silicate waste slag obtained by the factory using the electrothermal sublimation method to prepare Huanglin, and its vitreous content is 90%, and the potential mineral composition is mainly pseudolimestone (α-CS), lanceolite (C 3 S 2 ·CaF 2 ) and a small amount of apatite.

[0036] Further, the copper slag is the black granular waste slag discharged from the smelting plant, and its main potential mineral is fayalite (FeO SiO 2 ) and mullite (A 3 S 2 ), wherein the vitreous content is 80%.

[0037] Further, the fly ash comes from a power plant, which contains 80% glass and a small amount of α-quartz (α-SiO 2 ), the potential mineral is mullite (A 3 S 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com