Cotton-polyester speckled double-layer plain cloth fabric and weaving process thereof

A technology of gypsophila and fabrics, applied in the direction of fabrics, multi-strand fabrics, textiles and papermaking, etc., can solve the problems of not meeting the market's large-volume demand, high technical requirements, and high quality selection requirements, and achieve large market promotion value, The effect of low technical requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] The present invention realizes the purpose of weaving a cotton-polyester double-layer plain cloth fabric by relying on the change of the yarn raw material and the fabric structure.

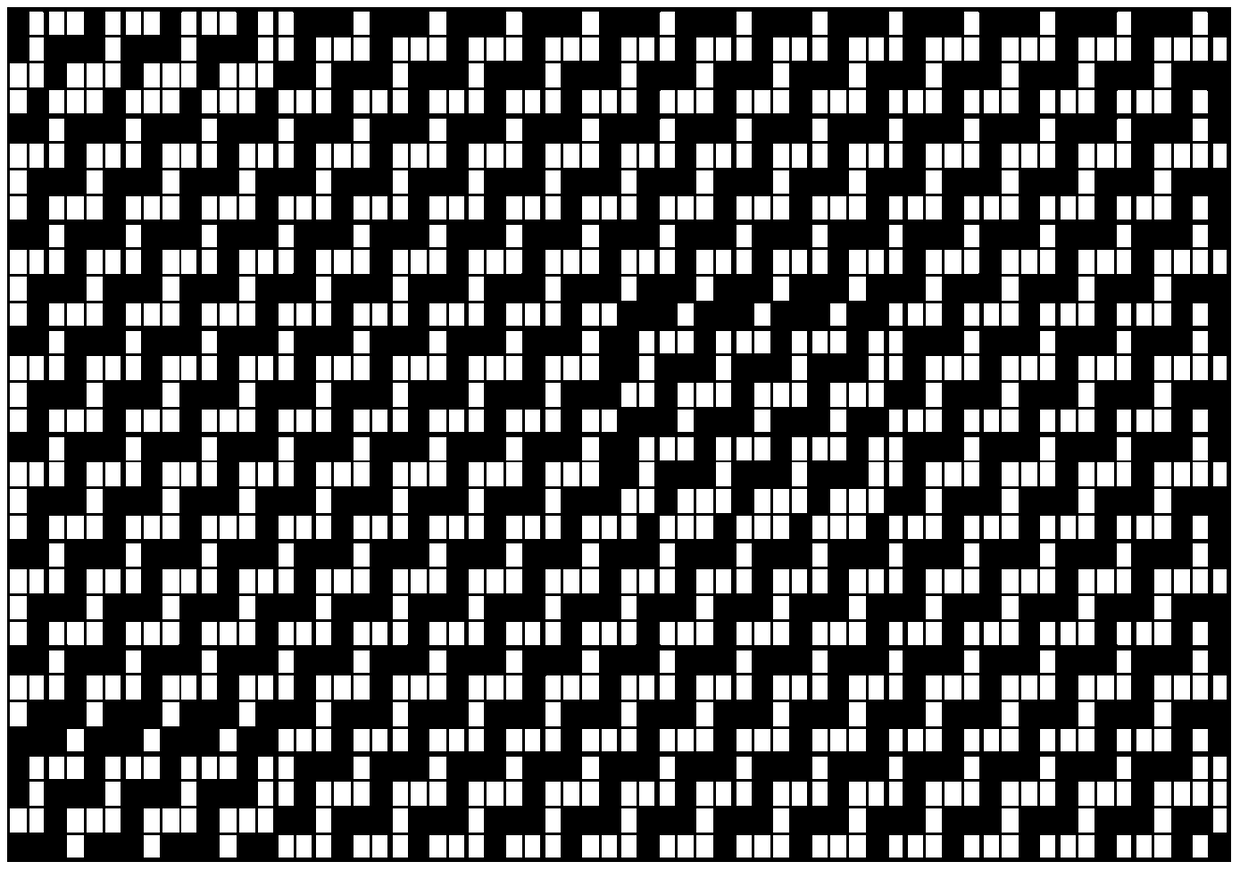

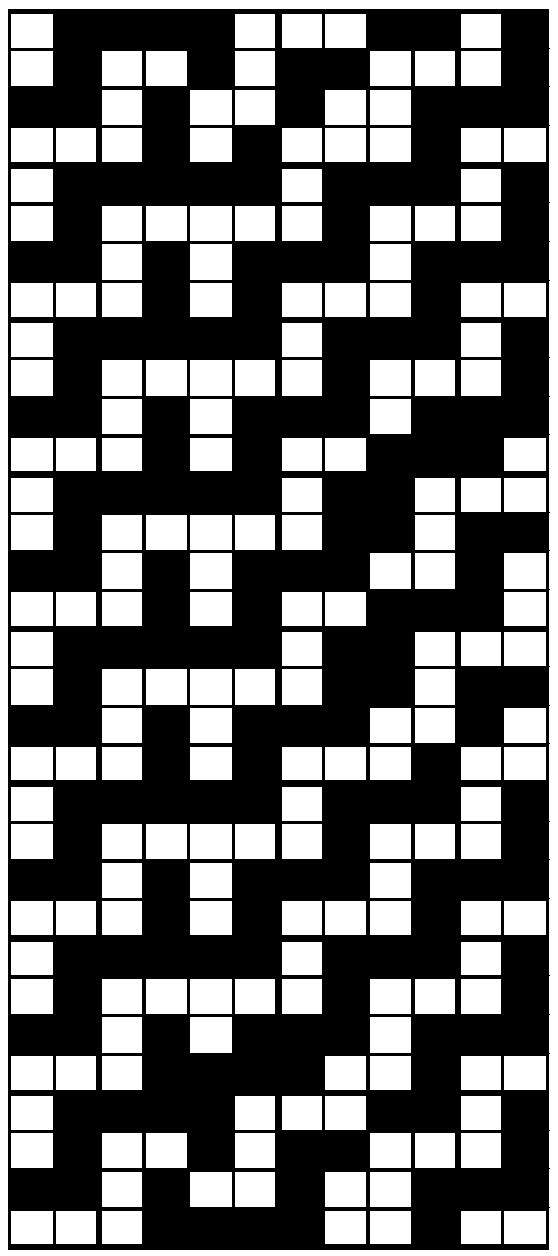

[0027] combined with Figure 1~2 , a kind of double-layer flat cloth fabric full of cotton and polyester, the fabric includes two kinds of yarns, cotton yarn and polyester yarn, and the cotton yarn is positioned at the front side of the fabric, and the polyester yarn is positioned at the back side of the fabric; the warp and weft yarns of the fabric are JC40s+T40s (1: 1)×JC40s+T40s(1:1), the warp and weft density is 160×130 threads / inch, the fabric width is 66 inches; the fabric satin is full of stars;

[0028] Among them: J stands for "combed", C stands for "cotton", JC40s stands for "combed cotton yarn of count 40", and T40s stands for "yarn of count 40 polyester yarn"....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com