Warp-knitted weft-knitted composite knitting system and knitting method

A technology of weft knitting and warp knitting, applied in weft knitting, warp knitting, knitting, etc., can solve problems such as non-existence, and achieve the effects of various changes, convenient control, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] Example 1

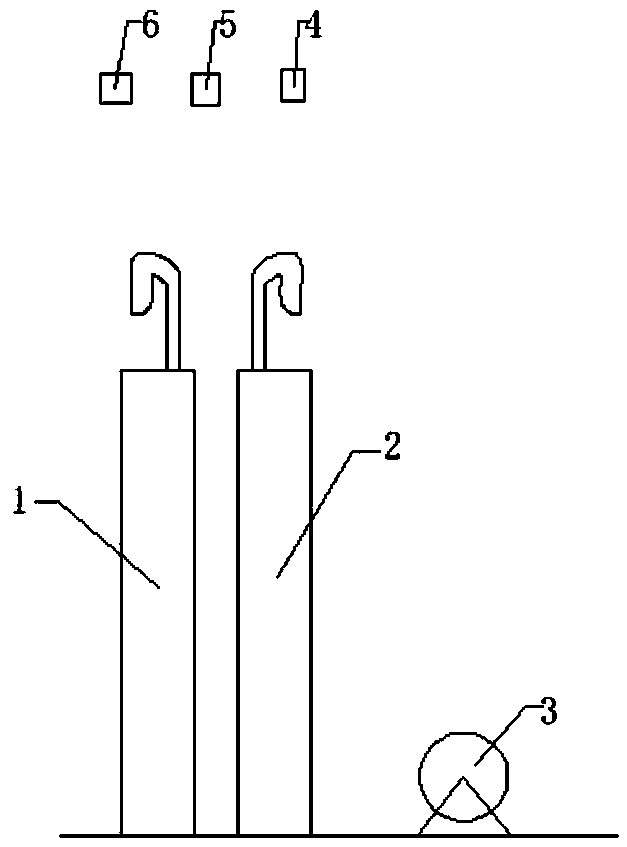

[0036] Such as figure 1 As shown, this embodiment 1 provides a warp-knitting and weft-knitting composite knitting system, including a warp-knitting machine tool 1, a weft-knitting machine tool 2, a cloth winding mechanism 3, a first yarn feeding mechanism 4, a second yarn feeding mechanism 5, and a second yarn feeding mechanism. Three yarn feeding mechanism 6;

[0037] The warp knitting machine tool 1 and the weft knitting machine tool 2 are arranged back to back in the front-to-back direction at intervals, and the number of knitting needles of the two is the same;

[0038] The first yarn feeding mechanism 4 is placed above the weft knitting machine tool 2 for feeding yarn to the weft knitting machine tool 2, and the third yarn feeding mechanism 6 is provided on the warp knitting machine tool 1. Above, it is used to feed yarn to the warp knitting machine tool 1, the warp knitting machine tool 1 and the weft knitting machine tool 2 synchronously knit the course, t...

Example Embodiment

[0046] Example 2

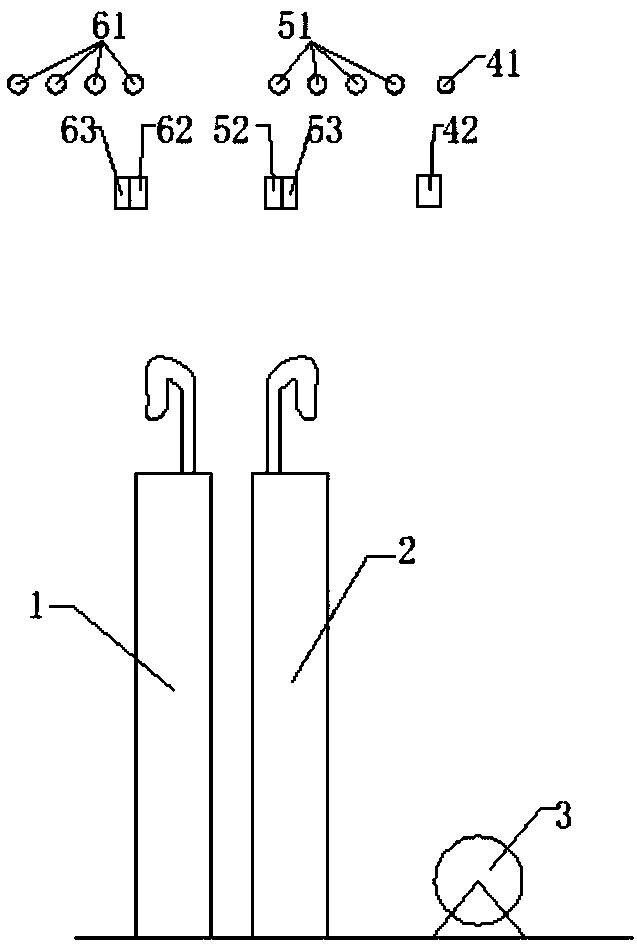

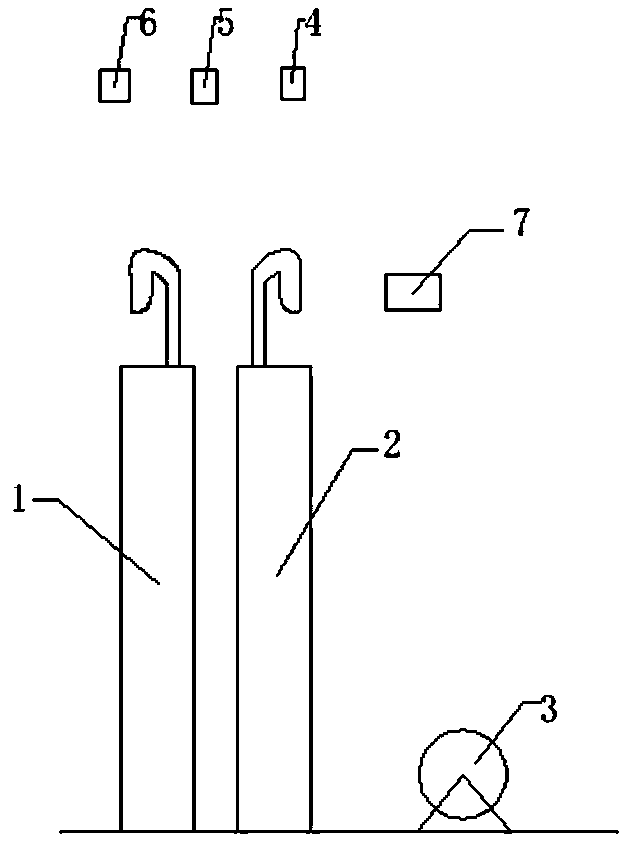

[0047] Such as Figure 3-5 As shown, it is the same as Embodiment 1, the difference is that the above technical solution also includes a transfer mechanism, and the transfer mechanism 7 is arranged on the rear side of the weft knitting machine tool 2, which is used to transfer several weft knitting machines of the weft knitting machine tool. The stitch of the needle is moved to the knitting needle adjacent to it.

[0048] Specifically, the transfer mechanism 7 in the above technical solution includes a two-dimensional moving platform 71, a mounting seat 72, a telescopic member 73, and a transfer needle 74, and the two-dimensional moving platform 71 is installed behind the weft knitting machine tool 2. , The mounting seat 72 is a bar-shaped rod, which is horizontally arranged in the left and right direction behind the knitting needles of the weft knitting machine tool 2, and the left and right sides of the mounting seat 72 respectively extend to and the weft knit...

Example Embodiment

[0054] Example 3

[0055] This embodiment provides a knitting method of the warp-knitting and weft-knitting composite knitting system as described in Embodiment 2. The weft-knitting machine tool 2 continuously knits, the warp-knitting machine tool 1 intermittently weaves, and the warp-knitting machine tool 1 and The weft-knitting machine tool 2 knits a course at the same time. After the warp-knitting machine tool 1 finishes weaving a course, it stops and waits for the weft-knitting machine tool 2 to knit the corresponding course after the two knitting the next course synchronously. Wherein, the first yarn feeding mechanism 4 sequentially lays all the knitting needles of the weft knitting machine tool 2 into loops one by one, and the third yarn feeding mechanism 6 synchronizes the multiple knitting needles of the warp knitting machine tool 1. After the yarn is formed into a loop, the second yarn feeding mechanism 5 is first moved to the top of the warp knitting machine tool 1 unde...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap