Piezoelectric substrate and surface acoustic wave device

A piezoelectric substrate, substrate technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, fabrication/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, etc. direction, can solve the problems of substrate edge defect, chipping, lower productivity, electrode short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

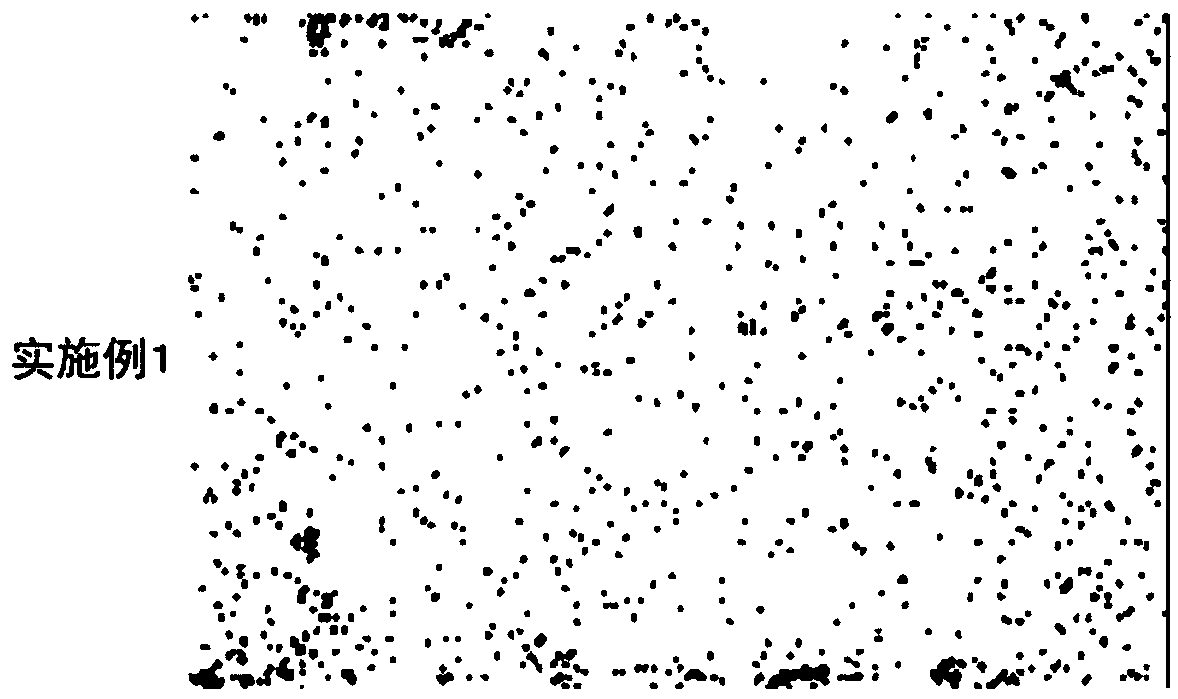

Embodiment 1

[0041] Using the raw materials of lithium carbonate and tantalum pentoxide (Japanese: raw materials), LT single crystal rods with a diameter of about 100 mm were grown by the Czochralski method. The obtained LT single crystal rod was subjected to peripheral grinding, slicing, and grinding to obtain a substrate with a thickness of 200 μm. The resulting substrate was mixed with KHCO 3 Together, heat treatment was performed at 550° C. for 2 hours under a nitrogen atmosphere to obtain an LT substrate.

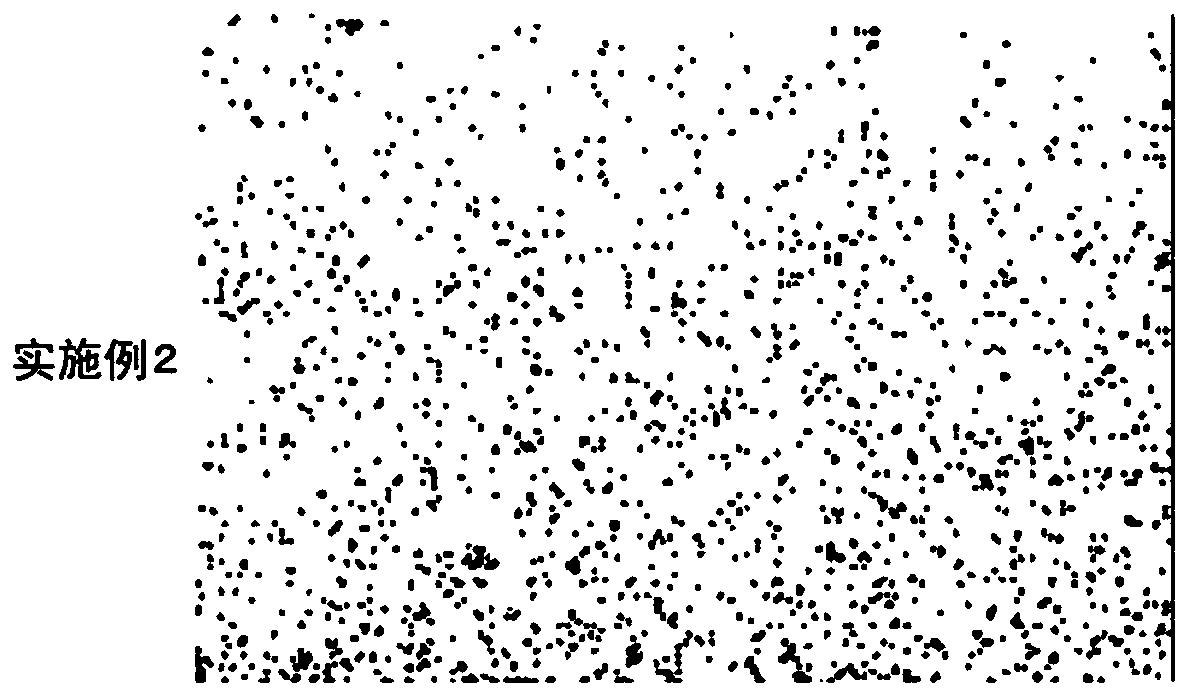

Embodiment 2

[0043] In order to examine the allowable degree of variation in characteristic values, an LT substrate was obtained in the same manner as in Example 1.

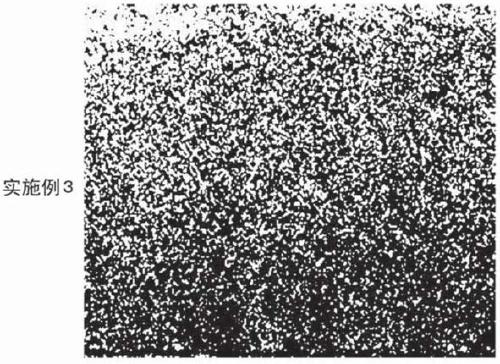

Embodiment 3

[0045] An LT substrate was obtained in the same manner as in Example 1 except that the processing temperature was set at 580°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com