Method for preparing magnesium-based catalyst for 1,3,3,3-tetrafluoropropylene through dehydrofluorination of 1,1,1,3,3-perfluoropropane

A technology for dehydrofluorination and tetrafluoropropene, which is applied in the direction of dehydrohalogenation preparation, physical/chemical process catalyst, catalyst activation/preparation, etc., can solve the problems of catalyst deactivation and increased separation cost, and achieve high catalytic activity and good life , highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

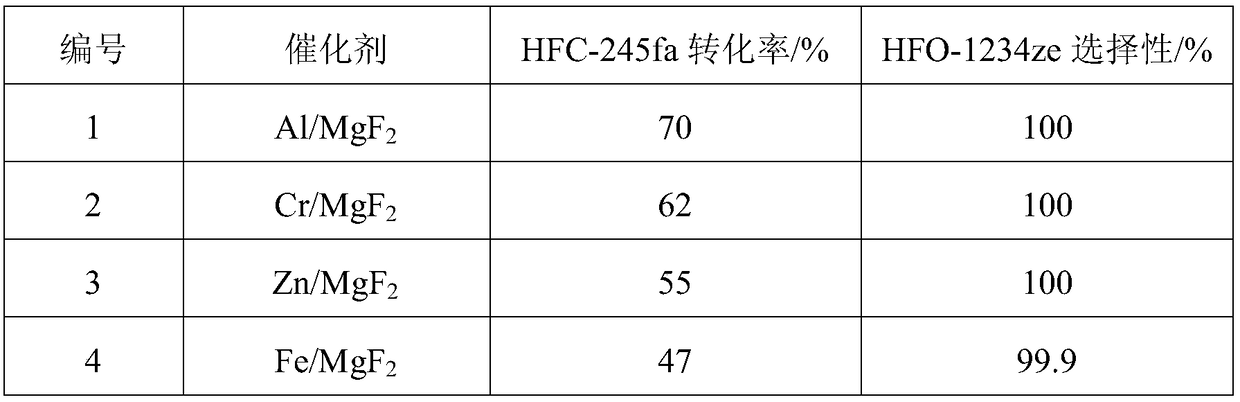

[0025] Dissolve 1 mol of magnesium source, a certain amount of active components and the same mass of complexing agent in 50 mL of polyol, and form a colorless and clear solution after a water bath temperature of 60°C and magnetic stirring; add a metered ratio of 40wt.% hydrofluoric acid, Continue the reaction for 6h; after aging at 80℃~100℃ for 24h, a solid gel is obtained; continue to dry at 110~150℃ to obtain magnesium fluoride xerogel, which is ground into powder, and finally calcined at 400℃ for 5h to obtain catalyst powder. Re-granulation, that is, the magnesium-based catalyst is prepared by the bulk doping method. The catalyst was applied to the HFC-245fa gas-phase dehydrofluorination synthesis reaction of HFO-1234ze. After running for 24 hours, the reaction results are shown in Table 1.

[0026] The active components introduced in Example 1 were Al(NO 3 ) 3 ·9H 2 O, Cr(NO 3 ) 3 ·9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O,...

Embodiment 2

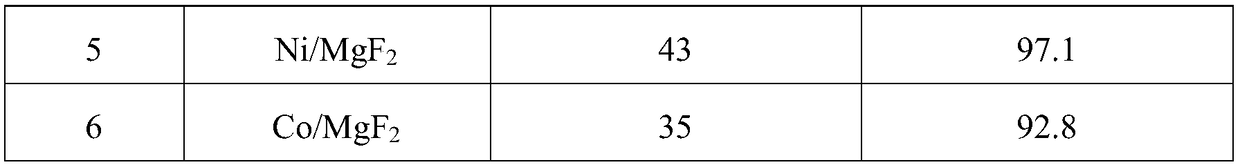

[0031] The active component introduced in this example is Al(NO 3 ) 3 ·9H 2 O, the molar ratio of active component to carrier ranges from 0.05 to 0.3.

[0032] The catalyst performance evaluation conditions are the same as in Example 1, and the catalyst evaluation results are shown in Table 2.

[0033] Table 2

[0034] Numbering

Embodiment 3

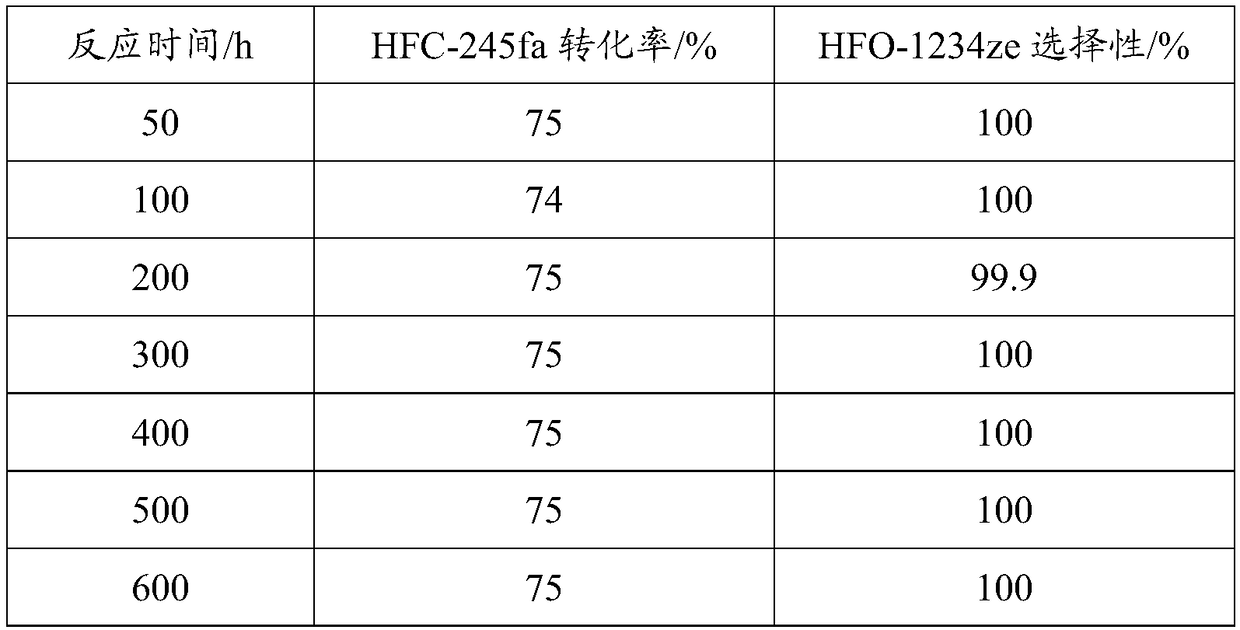

[0036] Take 20% Al / MgF numbered 4 in Example 2 2 The catalyst was subjected to a life test. The catalyst performance evaluation conditions were the same as in Example 1. The reaction was continuously run for 1000 hours. The evaluation results are shown in Table 3.

[0037] table 3

[0038]

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com