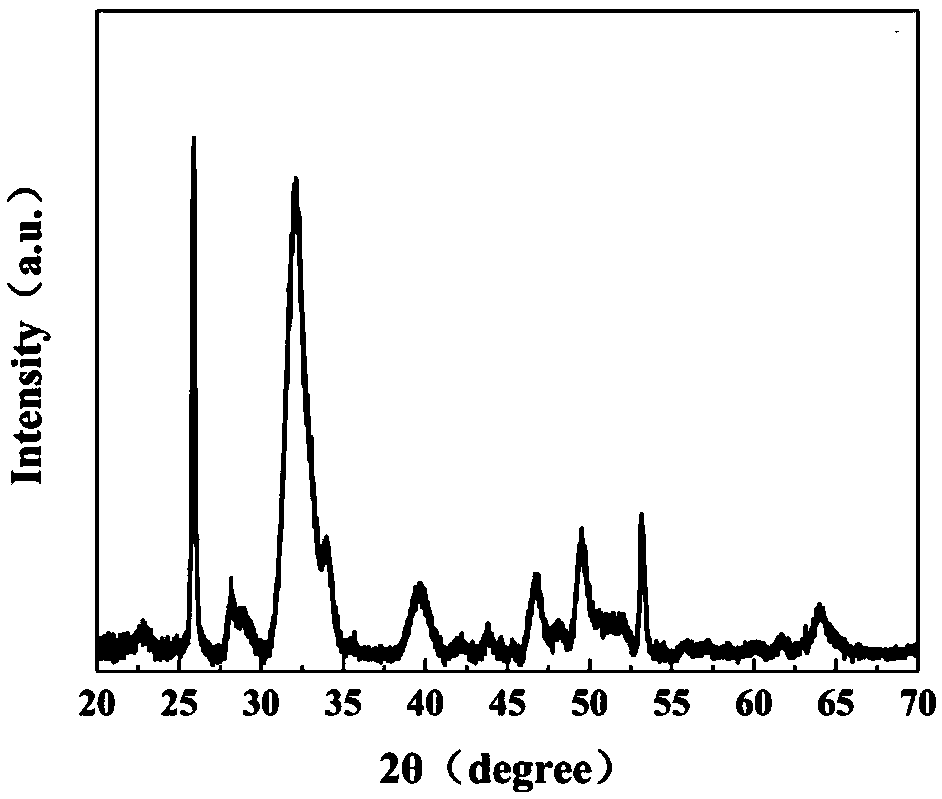

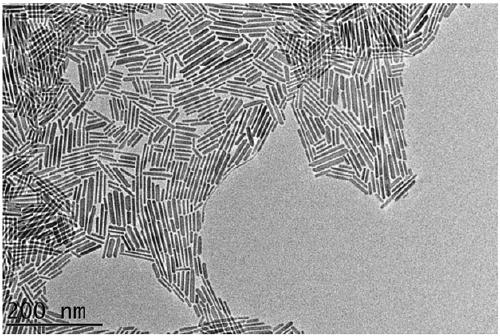

Two-step oil-solute hydroxyapatite nanorod preparing method

A hydroxyapatite, oil-soluble technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of nanocrystal crystallinity, morphology, size deficiency, material application cannot be realized, low solubility of sodium phosphate, etc. problems, to achieve the effects of good morphology controllability, low cost, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Dissolve 0.02mol calcium nitrate in 20g water to obtain solution A;

[0036] 2) Dissolve 0.032mol ethylenediamine in a mixture of 40g ethanol and 0.04mol oleic acid to obtain solution B;

[0037] 3) Add solution B obtained in step 2) into a three-necked flask, then slowly drop solution A obtained in step 1) into solution B, and stir for 10 minutes to obtain solution C;

[0038] The mol ratio of described oleic acid and calcium is 2:1;

[0039] The molar ratio of oleic acid to ethylenediamine is 5:4.

[0040] 4) Dissolve 0.012mol of trisodium phosphate in 30g of water to obtain solution D;

[0041] 5) Under stirring conditions, slowly drop the solution D obtained in step 4) into the solution C obtained in step 3), and continue stirring for 20 minutes after the dropwise addition to obtain a suspension;

[0042] 6) Centrifuge or filter the suspension obtained in step 5) to obtain a precipitate, redisperse the precipitate in 100 g of deionized water, and adjust the pH...

Embodiment 2

[0047] Embodiment 2, with embodiment 1, difference is,

[0048] 1) Dissolve 0.02mol calcium nitrate in 20g water to obtain solution A;

[0049] 2) Dissolve 0.032mol ethylenediamine in a mixture of 40g ethanol and 0.02mol oleic acid to obtain solution B;

[0050] 3) Add solution B obtained in step 2) into a three-necked flask, then slowly drop solution A obtained in step 1) into solution B, and stir for 10 minutes to obtain solution C;

[0051] The mol ratio of described oleic acid and calcium is 1:1;

[0052] The molar ratio of oleic acid to ethylenediamine is 5:4.

[0053] 4) Dissolve 0.012mol of trisodium phosphate in 30g of water to obtain solution D;

[0054]6) Centrifuge or filter the suspension obtained in step 5) to obtain a precipitate, redisperse the precipitate in 100 g of deionized water, and adjust the pH to 10.5 with 1 mol / L sodium hydroxide to obtain a reaction solution 1;

[0055] 7) The reaction solution 1 obtained in step 6) was placed in a high-temperatur...

Embodiment 3

[0056] Embodiment 3, with embodiment 1, difference is,

[0057] 1) Dissolve 0.02mol calcium nitrate in 20g water to obtain solution A;

[0058] 2) Dissolve 0.032mol sodium hydroxide in a mixed solution of 40g ethanol and 0.04mol oleic acid to obtain solution B;

[0059] 3) Add solution B obtained in step 2) into a three-necked flask, then slowly drop solution A obtained in step 1) into solution B, and stir for 10 minutes to obtain solution C;

[0060] The mol ratio of described oleic acid and calcium is 1:1;

[0061] The molar ratio of oleic acid to ethylenediamine is 5:4.

[0062] 4) Dissolve 0.012 mol of sodium dihydrogen phosphate in 30 g of water to obtain solution D;

[0063] 6) Centrifuge or filter the suspension obtained in step 5) to obtain a precipitate, redisperse the precipitate in 100 g of deionized water, adjust the pH to 7 with 1 mol / L sodium hydroxide, and obtain a reaction solution 1;

[0064] 7) The reaction solution 1 obtained in step 6) was placed in a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com