Quantitative measurement method for putty sanding property

A test method and grinding technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of low reliability of test results, low strength of putty, difficult grinding, etc., and achieve accurate measurement and judgment results and easy operation. , measuring simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

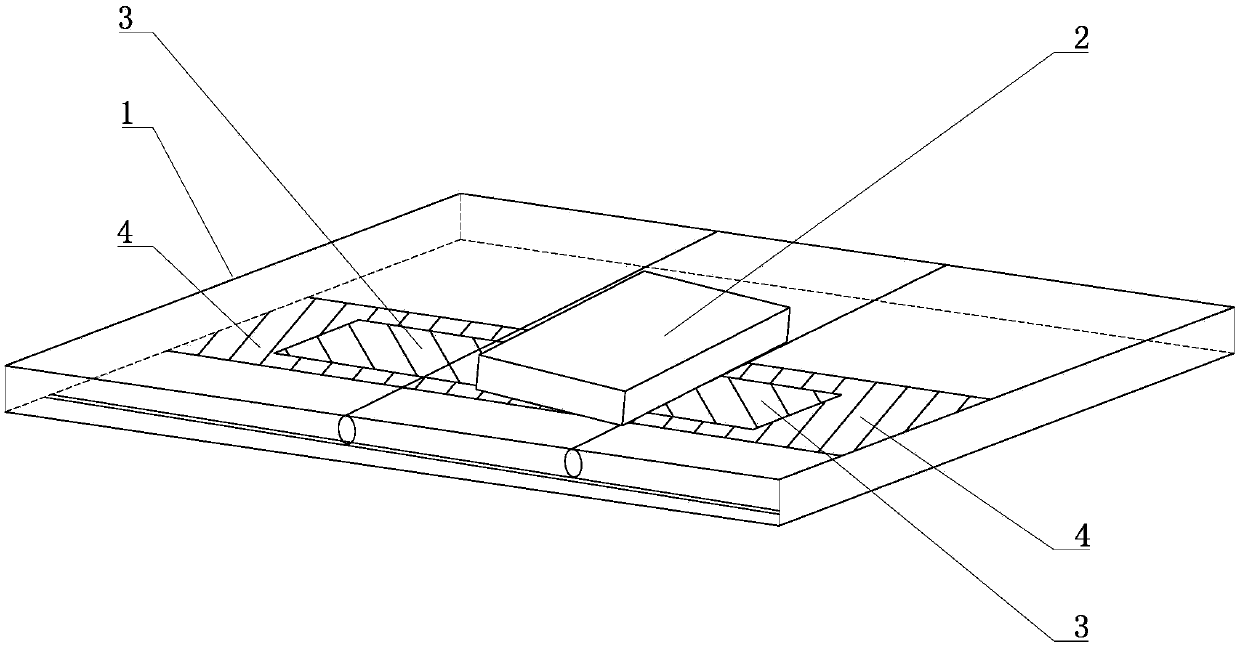

[0026] The present invention will be further described in detail below in conjunction with the drawings.

[0027] The method for quantitative testing of putty sandability of the present invention includes the following steps:

[0028] A. Weigh the putty powder for experiment, add it to the water according to the formula ratio, stir it evenly, leave it for 5 minutes, and then stir for 2 minutes;

[0029] B. Use a rectangular metal frame to scrape the mixed putty with a weight of M 0 The film is completed on the cement board with a wet film thickness of 2mm;

[0030] C. Place curing at room temperature for 24 hours, weigh the total weight of putty layer 3 and cement board 4 after curing M 1 ;

[0031] D. Use a 1kg briquette 2 with 120 mesh dry sanding paper on the bottom surface and place it on the architectural coating scrubbing resistance instrument, and polish the putty layer 10 times after curing, and weigh the total of the putty layer 3 and cement board 4 after polishing 10 times. W...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap