Stationary anodes and x-ray radiators for x-ray radiators

A technology for fixing anodes and X-rays. It is used in X-ray tube anode cooling, X-ray tube electrodes, and X-ray tube components. It can solve problems such as easy damage to the coating, and achieve improved heat dissipation and high reproducibility. The effect of high stability and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

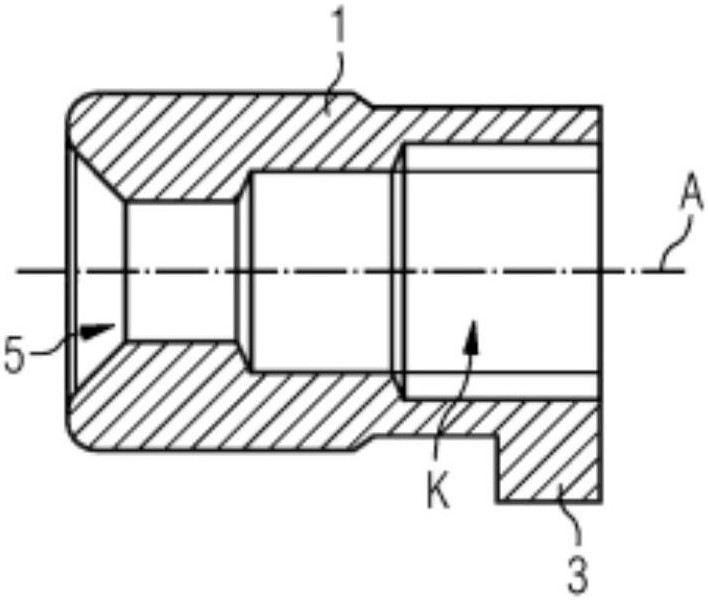

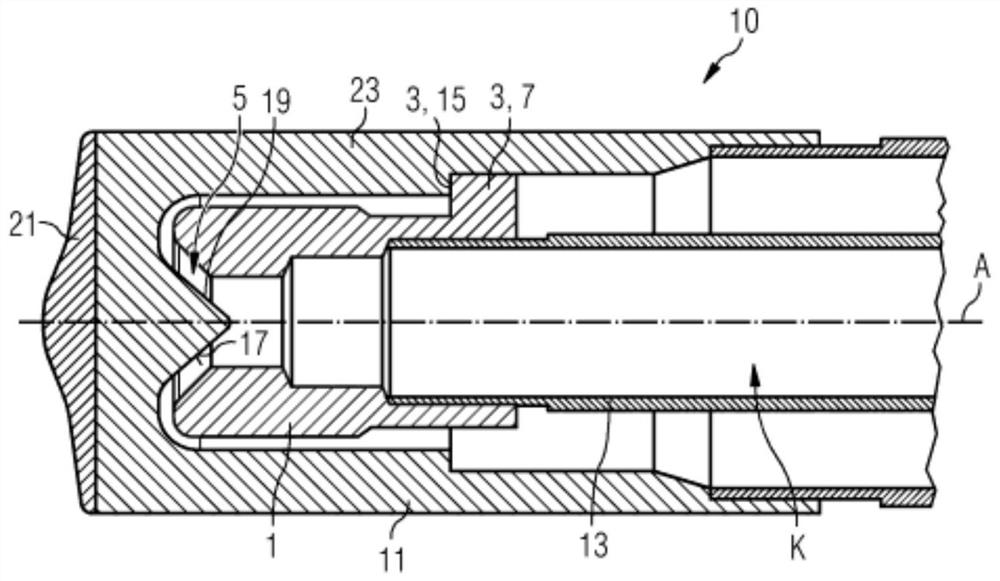

[0034] figure 1 shown for use in figure 2 The nozzle 1 of the stationary anode 10 is shown in detail in .

[0035] The nozzle 1 has a cooling channel K that tapers in the axial direction A for conveying a cooling fluid, in particular fully desalinated water, which diverges at the end into a funnel-shaped outflow opening 5 .

[0036] Furthermore, the nozzle has three stop elements 3 in the form of radially protruding webs 7, wherein figure 1 Only one of the stop elements is located in the section plane shown. The stop elements 3 formed as webs 7 are arranged circumferentially at an angular distance of 120° and serve to fix and center the nozzle 1 relative to the anode base body 11 of the stationary anode 10 so that the cooling channel K is fixed within the stationary anode 1 . Mind stretched. For this purpose, the nozzle 1 is connected at its end facing away from the outflow opening 5 with a delivery pipe 13 which delimits the cooling channel K in sections.

[0037] The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com