Adsorbent and method for treating exhaust gas containing sulfur dioxide

A sulfur dioxide and adsorbent technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low utilization rate of lye and desulfurization rate, improve adsorption performance and selective absorption performance, and improve treatment efficiency. , the effect of strong absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

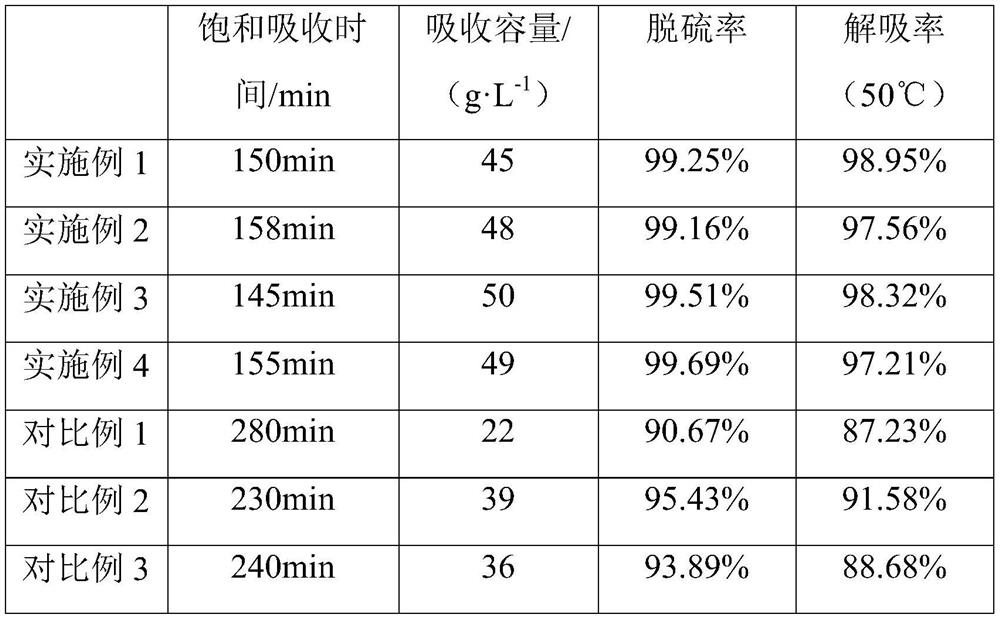

Examples

Embodiment 1

[0032] An adsorbent for treating exhaust gas containing sulfur dioxide: 19.5% diphenylsulfoxide, 10% 2,3-diphenylpiperazine, 30% tetraethylene glycol dimethyl ether, 0.5% copper sulfate and 40% deionized water .

[0033] The preparation method of above-mentioned adsorbent comprises the steps:

[0034] Weigh each component according to the designed proportion, mix each component uniformly, heat to 40° C., and stir at 300 rpm for 1 h to obtain the adsorbent.

[0035] The method for utilizing the above-mentioned adsorbent to treat exhaust gas containing sulfur dioxide comprises the following steps:

[0036] At a temperature of 30°C, the exhaust gas containing sulfur dioxide is 3 The speed of / h passes in the above-mentioned adsorbent, detects the outlet sulfur dioxide content, when the sulfur dioxide concentration reaches 0.8mg / L, stop ventilating, under the stirring speed of 100rpm, add 15wt% sodium carbonate solution 750g in every liter of adsorbent, separate The aqueous pha...

Embodiment 2

[0038] An adsorbent for treating exhaust gas containing sulfur dioxide: 15% diphenylsulfoxide, 7% 2,3-diphenylpiperazine, 27% tetraethylene glycol dimethyl ether, 1% copper nitrate and 50% deionized water .

[0039] The preparation method of above-mentioned adsorbent comprises the steps:

[0040] Weigh each component according to the designed proportion, mix each component uniformly, heat to 45° C., and stir at 500 rpm for 0.5 h to obtain the adsorbent.

[0041] The method for utilizing the above-mentioned adsorbent to treat exhaust gas containing sulfur dioxide comprises the following steps:

[0042] At a temperature of 20°C, the exhaust gas containing sulfur dioxide is 3 The discharge speed of / h is passed in the above-mentioned adsorbent, detects outlet sulfur dioxide content, when sulfur dioxide concentration reaches 0.8mg / L, stops ventilating, under the stirring speed of 150rpm, adds the sodium carbonate solution 550g of 20wt% in every liter of adsorbent, The aqueous p...

Embodiment 3

[0044] An adsorbent for treating exhaust gas containing sulfur dioxide: 20% diphenylsulfoxide, 5% 2,3-diphenylpiperazine, 15% tetraethylene glycol dimethyl ether, 2% copper chloride and 58% deionized water %.

[0045] The preparation method of above-mentioned adsorbent comprises the steps:

[0046]Weigh each component according to the designed ratio, mix each component uniformly, heat to 50° C., and stir at 450 rpm for 1.5 h to obtain the adsorbent.

[0047] The method for utilizing the above-mentioned adsorbent to treat exhaust gas containing sulfur dioxide comprises the following steps:

[0048] At a temperature of 60°C, the exhaust gas containing sulfur dioxide is 3 The discharge speed of / h is passed in the above-mentioned adsorbent, detects outlet sulfur dioxide content, when sulfur dioxide concentration reaches 0.8mg / L, stops ventilating, under the stirring velocity of 100rpm, adds the sodium carbonate solution 450g of 25wt% in every liter of adsorbent, The aqueous ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com