Method for harvesting oil-producing microalgae in urban sewage culture system on large scale by using magnetic particles

A magnetic particle and urban sewage technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low efficiency, high cost, slow speed, etc., and achieve improved separation efficiency, small secondary pollution, The effect of short separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

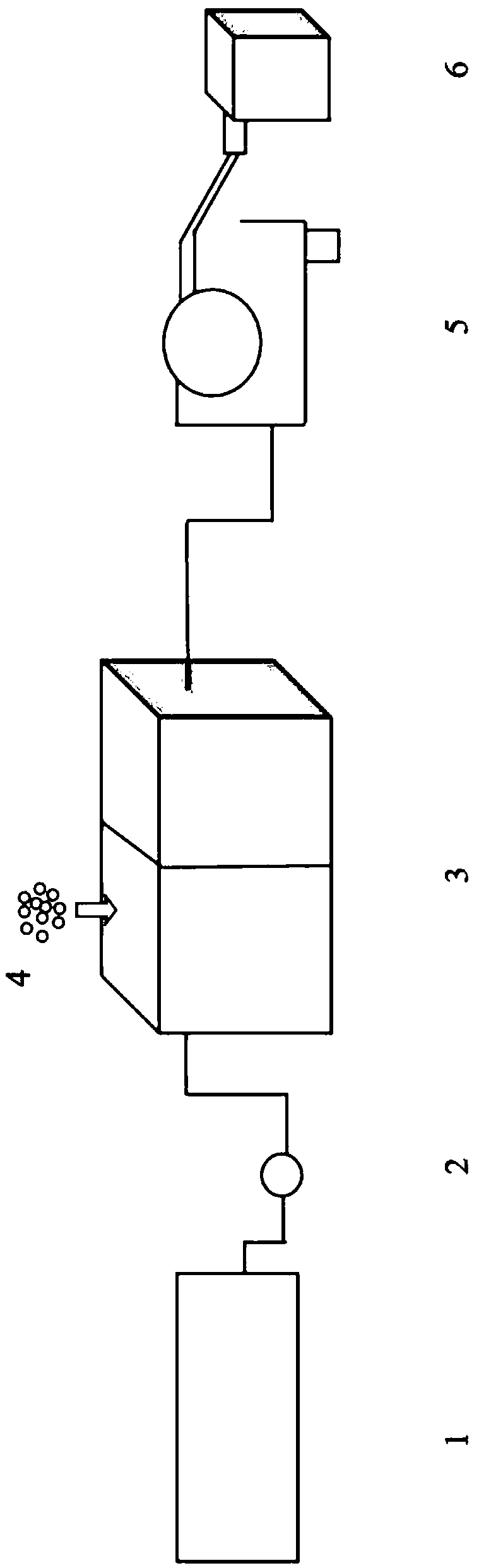

Image

Examples

Example Embodiment

[0031] Example 1

[0032] A method for large-scale harvesting of oil-producing microalgae in urban sewage culture system using magnetic particles. The total nitrogen content is 50mg / L, the total phosphorus content is 5mg / L, and the urban sewage with a pH of 7 is filtered through a 50-mesh filter and enters the outdoors. Cultivate oil-producing microalgae in the racetrack pond. When the microalgae reaches a stable growth period and the concentration of the algae solution is 0.8g / L, the algae solution is introduced into the sub-velocity stirring tank through a water pump. Join Fe 3 O 4 The mass ratio with PAC is 1:3. The magnetic particle flocculant prepared by co-precipitation method is 0.5g / L, stirred at 800r / min for 3min, and stirred at 200r / min for 5min. After mixing, it flows through the magnetic separator continuously, and the algae is on the disk. The supernatant is harvested, the supernatant flows out, the hydraulic retention time is 3 minutes, and the microalgae harvest ra...

Example Embodiment

[0033] Example 2

[0034] A method for large-scale harvesting of oil-producing microalgae in urban sewage culture system by using magnetic particles. The total nitrogen content is 60mg / L, the total phosphorus content is 6mg / L, and the urban sewage with a pH of 7 is filtered through a 60-mesh filter and enters the outdoors. Cultivate oil-producing microalgae in the racetrack pond. When the microalgae reaches a stable growth period and the concentration of the algae solution is 1.0g / L, the algae solution is introduced into the sub-speed mixing tank through a water pump. Join Fe 3 O 4 The mass ratio to PAC is 1:2, 0.6g / L of magnetic particle flocculant prepared by co-precipitation-sol-gel method, stirring at 800r / min for 4min, stirring at 200r / min for 6min, and then continuously flowing through the magnetic separator after uniform mixing , The algae is harvested on the disk, the supernatant flows out, the hydraulic retention time is 4min, and the microalgae harvest rate can reach 99...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap