A new energy vehicle synchronous reluctance motor control method based on AC step control

A technology for synchronous reluctance motors and new energy vehicles. It is applied in the direction of AC motor control, generator control, motor generator control, etc. It can solve problems such as the influence of calculation accuracy, poor low-speed performance, and complex system structure, and achieve improvement. Control effect, strong current followability, small torque ripple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

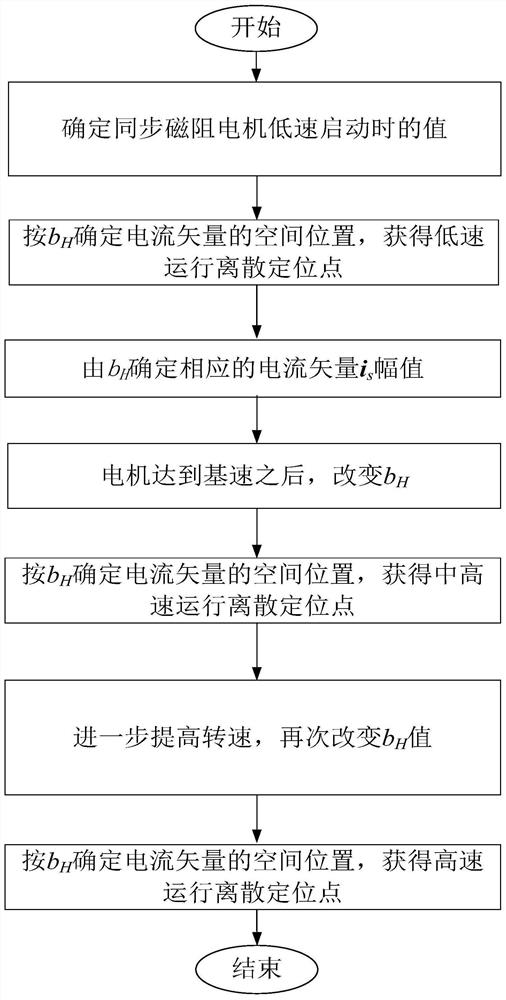

[0153] The AC stepping control method of a synchronous reluctance motor in this embodiment includes the following steps:

[0154] In this embodiment, the motor to be controlled is a salient pole rotor synchronous reluctance motor with a power of 11kw, a rated voltage of 310v, a rated current of 22.2A, and a rated speed of 1500 Rpm.

[0155] Figure 7 The illustrated embodiment shows that the composition of the device used in the operating method of the synchronous reluctance motor AC step control of the present invention includes a DSP control module 1, a power circuit 2, a synchronous reluctance motor 3, an encoder position detection module 4 and an input power supply module 5 , wherein, the input power supply module 5 supplies power for the DSP control module 1, the power circuit 2 and the encoder position detection module 3, and the DSP control module 1, the power circuit 2, the synchronous reluctance motor 3 and the encoder position detection module 4 are sequentially conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com