a graphite base

A technology of graphite base and circular groove, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of poor luminous uniformity of epitaxial wafers and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]In order to make the objects, technical solutions, and advantages of the present invention, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

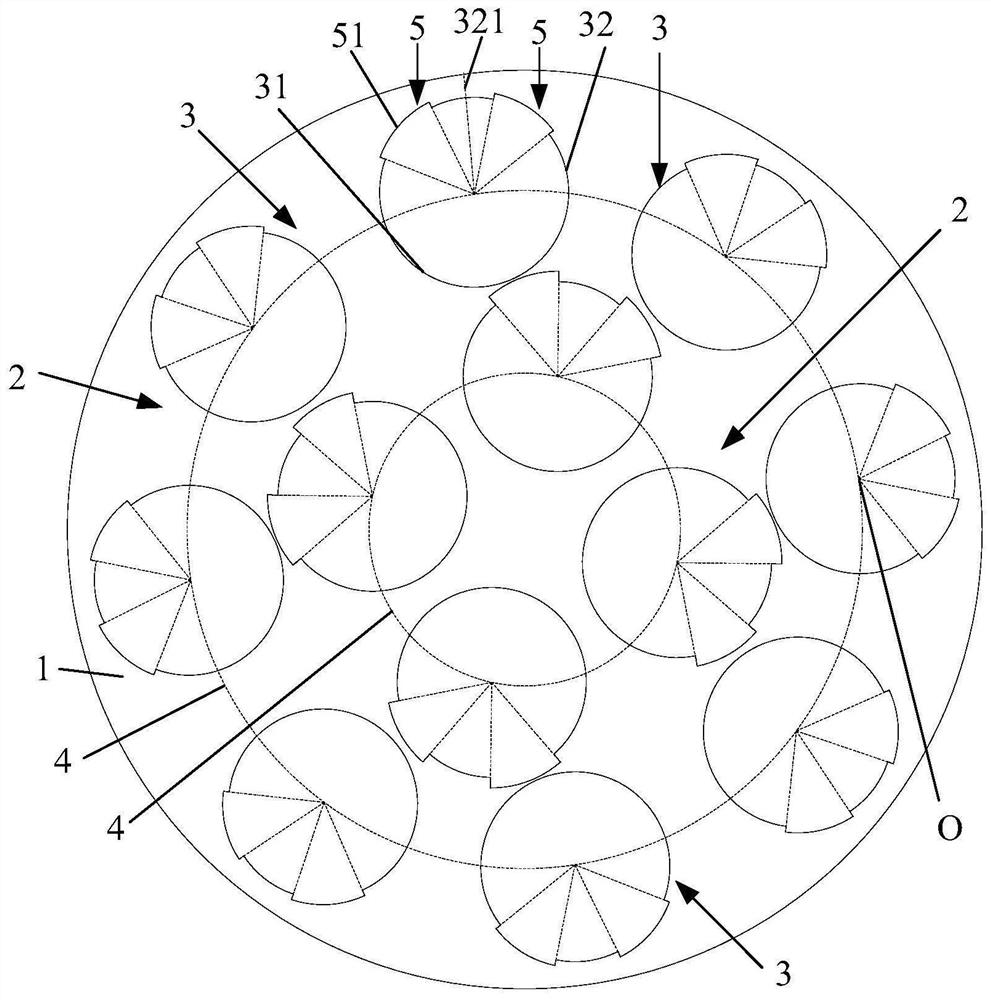

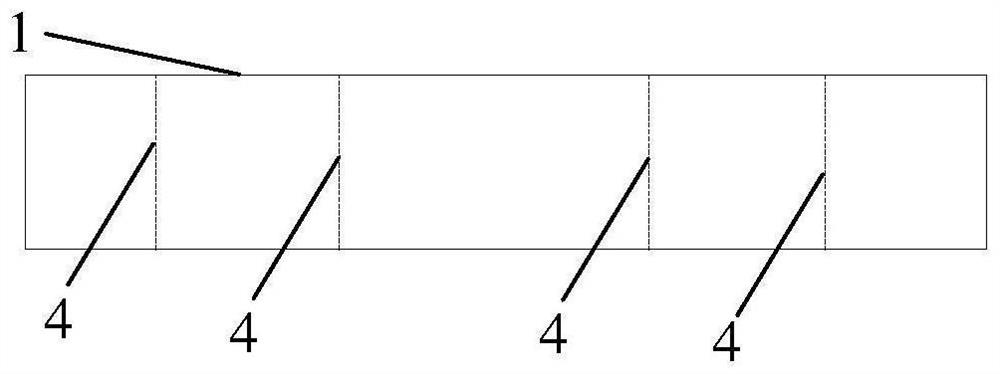

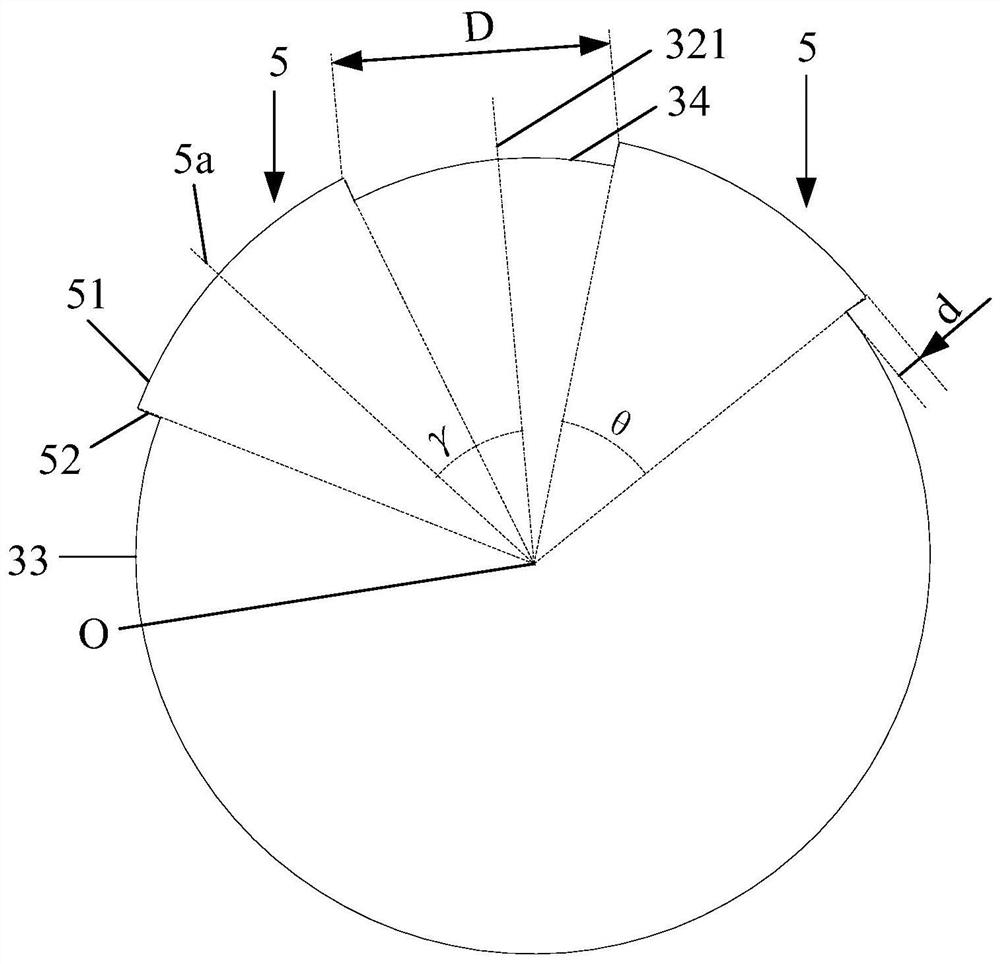

[0025]figure 1 It is a structural view of a graphite base provided by the embodiment of the present invention.figure 2 It is a side view of a graphite base provided in the embodiment of the present invention, combinedfigure 1 versusfigure 2 The graphite base is a cylinder. A multi-set circular groove unit 2 is provided on the end face 1 of the graphite base, and the plurality of circular groove unit 2 taken along the end face 1 of the graphus base, each group of circular groove unit 2 includes more A circular groove 3, a plurality of circular grooves 3 along the circumference of the end face 1 of the graphite base, and the center O of the plurality of circular grooves 3 is in the same cylindrical surface 4.

[0026]The cylindrical surface 4 divides each of the circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com