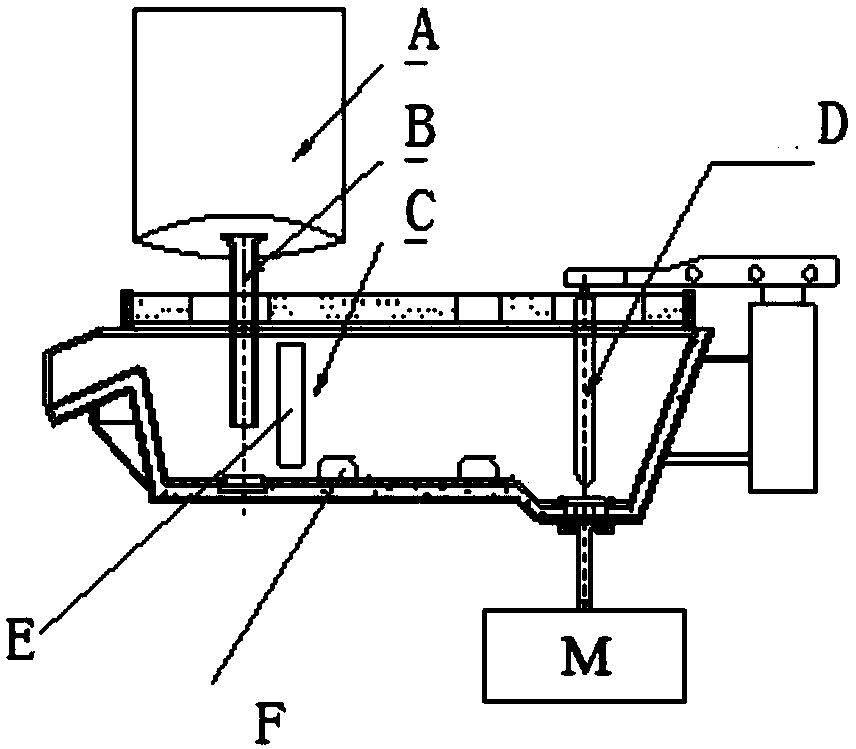

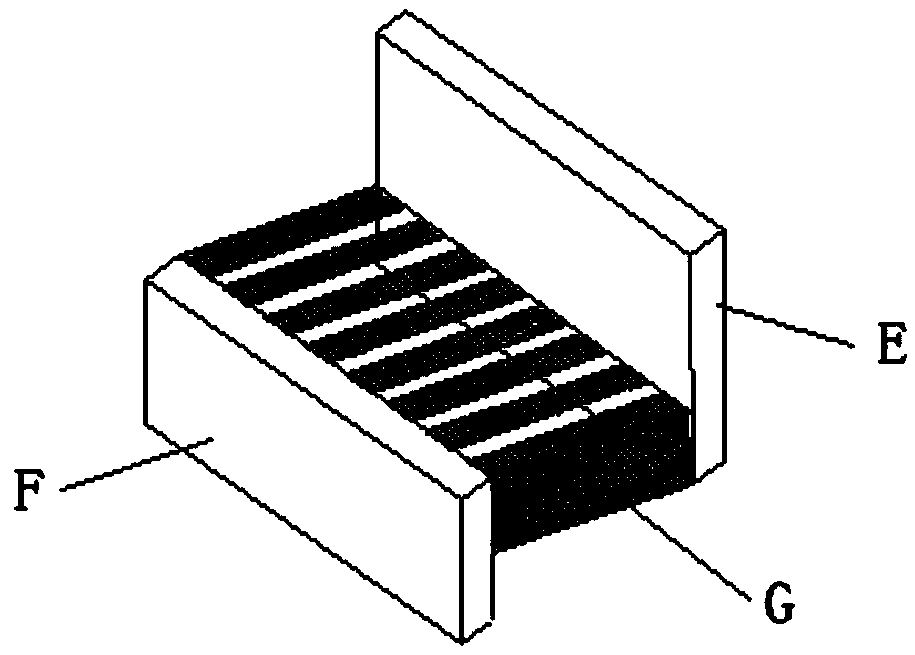

Tundish of barricade and retaining dam structure and masonry method of tundish

A tundish and retaining dam technology, which is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problem that the molten steel cannot provide enough upward force of the flow field, the effect is not very ideal, and the tundish retaining wall has a large gap and other problems, to achieve the effect of promoting the floating of inclusions, increasing the cleanliness, and improving the degree of lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After implementing the tundish of the retaining wall and dam structure of the present invention on the wide and thick plate production line, the cleanliness of molten steel has been effectively improved. The detection of inclusions in cast steel shows that the B-type oxidized inclusions have been reduced from 1.0 to 0.5, and the cleanliness of molten steel has increased. a grade.

Embodiment 2

[0027] After implementing the tundish of retaining wall and dam structure of the present invention on the wide and thick plate production line, the weight of unqualified steel plate flaw detection caused by excessive inclusions in the steel dropped from an average of 45 tons / month to an average of 10 tons / month.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com