High-efficiency chemical mixing device

A mixing device and chemical technology, applied in the field of high-efficiency chemical mixing devices, can solve the problems of affecting the effect of mixing, affecting the effect of stirring, difficult to clean and maintain, and achieve the effect of enhancing the stirring effect, improving the stirring effect and facilitating daily maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example one

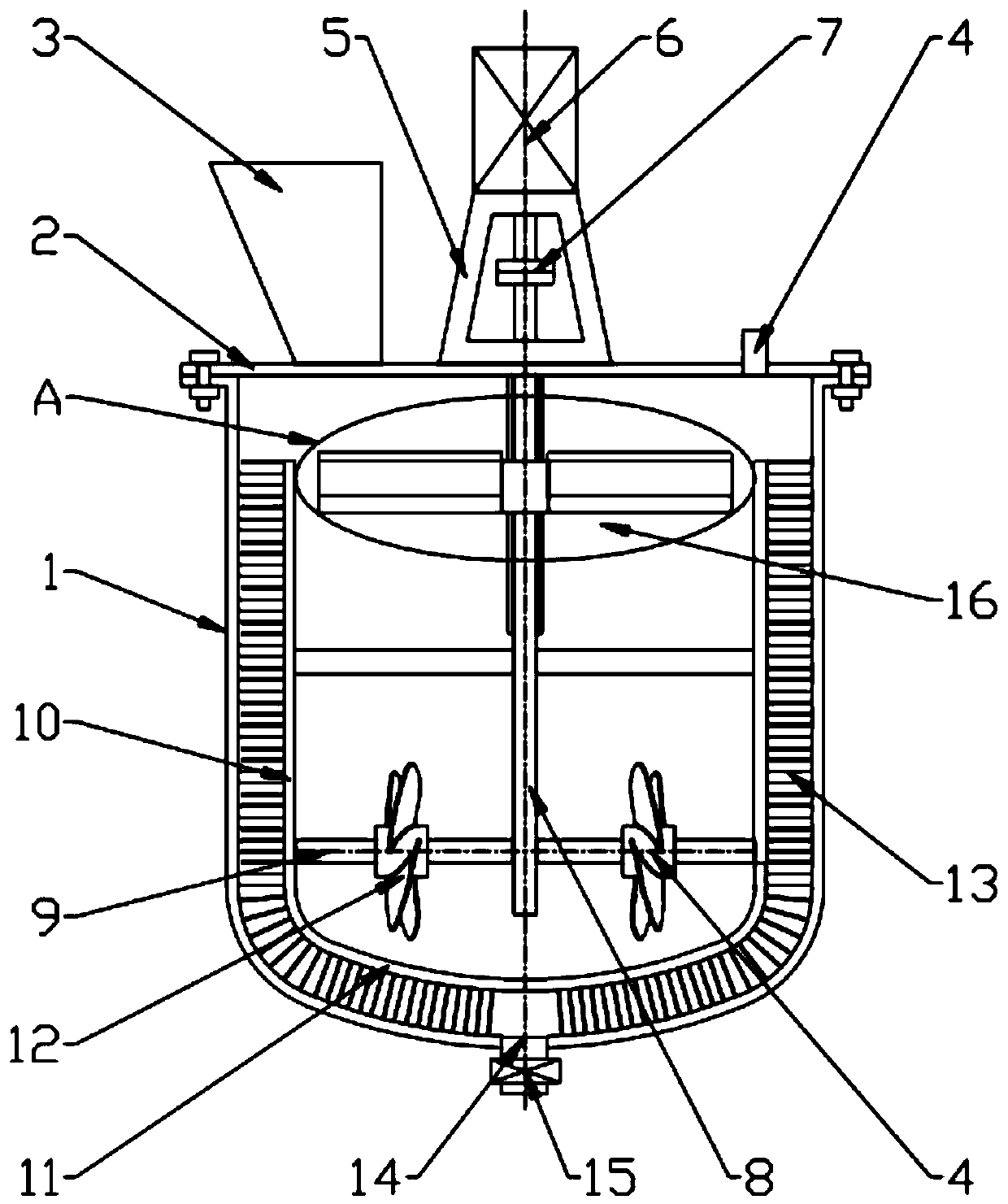

[0024] See Figure 1-3 , A high-efficiency chemical mixing device, comprising a casing 1, an upper cover 2, a hopper 3, a cleaning port 4, a motor support 5, a motor 6, a coupling 7 and a stirring shaft 8; the casing 1 is arranged above The upper cover 2 is provided with a discharge port 14 at the bottom; the upper side of the upper cover 2 is provided with a feed hopper 3 on the left side, and a cleaning port 4 is provided on the right side. A motor support 5 is installed in the center; a motor 6 is installed above the motor support 5 , A coupling 7 is set in the center; a stirring shaft 8 is fixed below the coupling 7; a defoaming device 16 is set in the middle of the stirring shaft 8, and a horizontal support rod 9 is set at the bottom; the horizontal support rod 9 is provided with or without power The outer end of the impeller 12, the horizontal support rod 9 is connected to the vertical mounting plate 10; the outside of the vertical mounting plate 10 is...

Example Embodiment

[0026] Example two

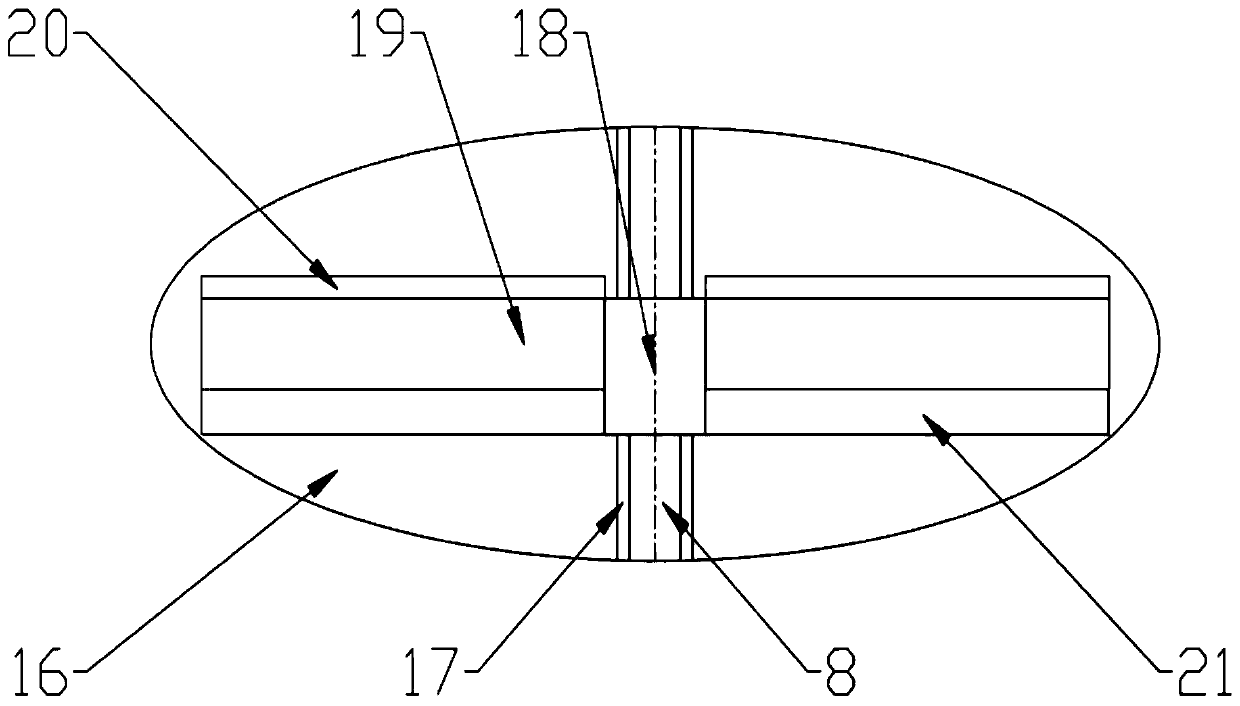

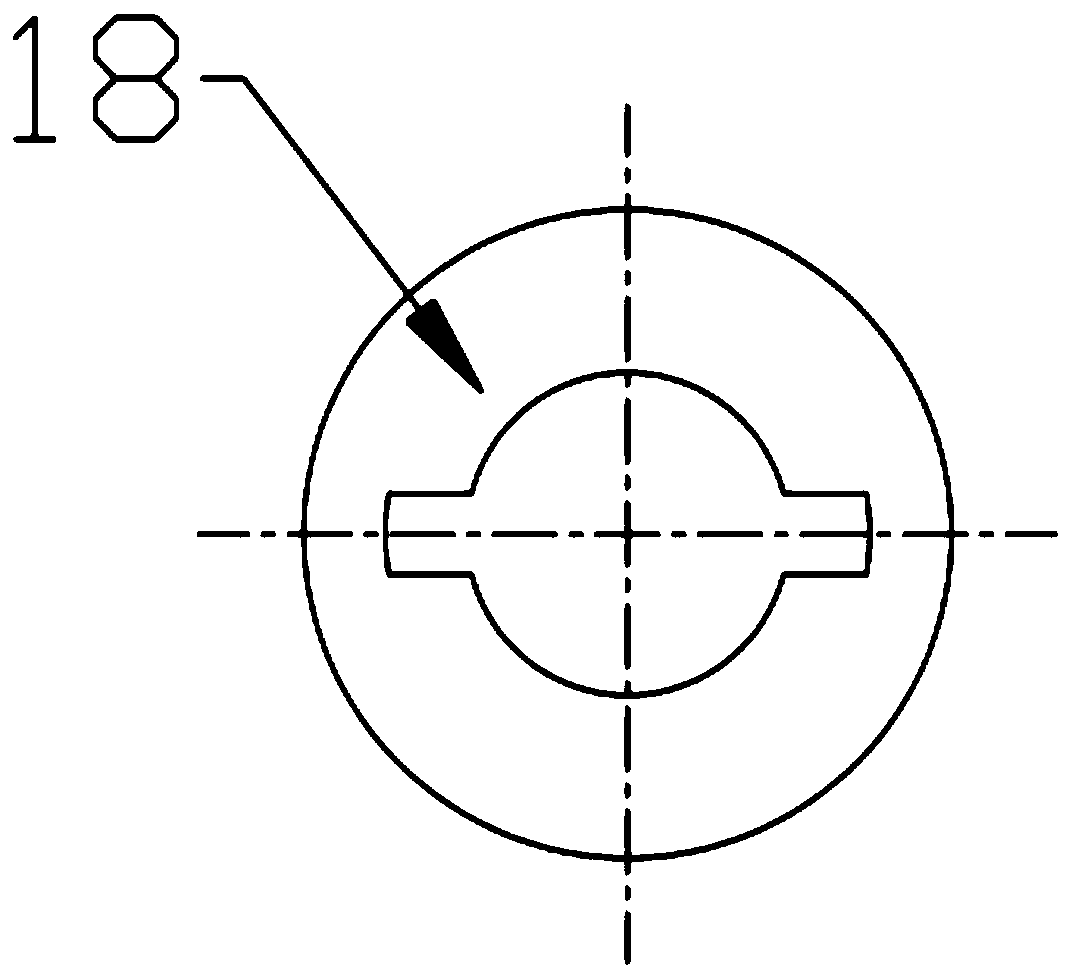

[0027] See Figure 1-3 , A high-efficiency chemical mixing device, the defoaming device 16 includes a guide sleeve 18; the left and right sides of the guide sleeve 18 are respectively provided with a defoaming rod 19; the upper surface of the defoaming rod 19 is provided with a defoaming net 20 , The lower surface is provided with a floating block 21; the guide sleeve 18 is sleeved in the middle of the stirring shaft 8 and can slide freely up and down; the middle surface of the stirring shaft 8 is provided with a guide plate 17; the guide sleeve 18 is provided with and The guide plate 17 is slidingly matched with the groove; the floating block 21 in the defoaming device 16 drives the guide sleeve 18 and the defoaming rod 19 to float up and down along the guide plate 17 on the stirring shaft 8 as the liquid level of the material changes. The bubble net 20 removes bubbles on the surface of the liquid surface and improves the mixing effect.

[0028] The working ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap