A kind of graft copolymer of cellulose and its derivatives and PET and its synthetic method

A technology of graft copolymer and synthesis method, applied in the field of graft copolymer of cellulose and its derivatives and PET and its synthesis, can solve the problems of long reaction time and less than 60% graft rate of CDA and PET, etc. , to achieve the effect of increasing the grafting rate, shortening the grafting time and improving the grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

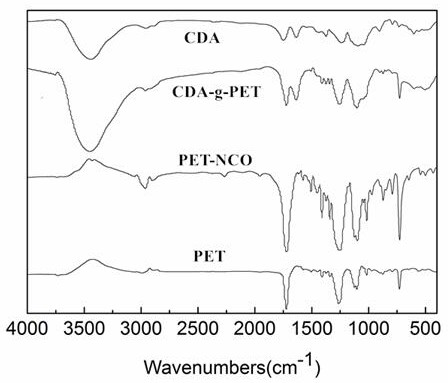

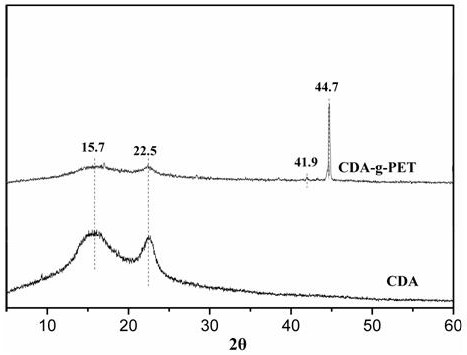

Method used

Image

Examples

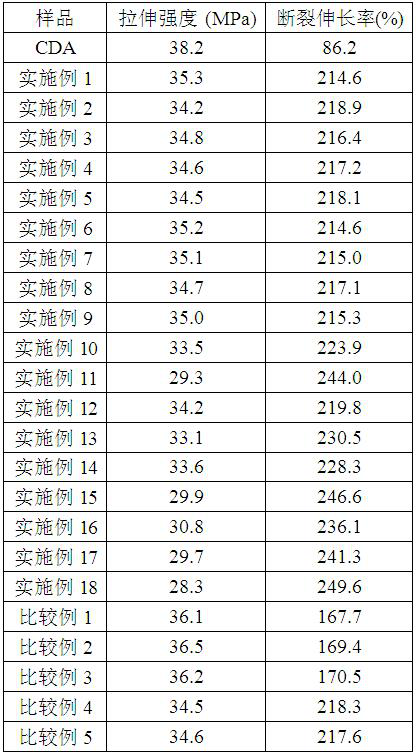

Embodiment 1

[0037] First, dissolve 0.0348g of ethylene glycol antimony in 10mL of ethylene glycol, add 66.4g of terephthalic acid, add 34.6ml of ethylene glycol and 6.33g of n-decyl alcohol. The reaction was carried out at 230°C under normal pressure for about 11 h until the system became transparent and the esterification reaction was completed. Then add 1.66g of trimethyl phosphate, evacuate to 5000Pa and heat up to 265°C, react for 50 minutes, stop the reaction, pour the produced product into water while it is hot, and obtain PET with a number average molecular weight of 2565.

[0038] Take 1 gram of PET with a molecular weight of 2565 and dissolve it in 10 mL of tetrachloroethane, add 0.045 g of isophorone diisocyanate, 0.1 mL of dibutyltin dilaurate and 0.04 g of 1-butyl-3-methylimidazolium dibutyl phosphate ester, and reacted at 70°C for 6 hours to obtain an isocyanate-terminated prepolymer. 1 gram of nanocrystalline cellulose with a number-average molecular weight of 50,000 was ul...

Embodiment 2

[0040] Same as Example 1, except that the monohydric alcohol adopts benzyl alcohol. The grafting rate is 50%, and the mechanical property test results of the sample film are shown in Table 1.

Embodiment 3

[0042] Same as Example 1, except that: n-nonanol is used as monohydric alcohol. The grafting rate is 47%. The mechanical property test results of the sample film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com